Introduction

Lithium-ion batteries promote power storage innovation that supports electronic devices including phones and vehicles and runs large energy systems with increased capacity . Parallel lithium-ion batteries now lead other technology choices in storing energy thanks to their development. Parallel connection of cells within a battery system enhances capacity without affecting voltage. The setup delivers beneficial features for consuming higher power levels or sustaining operation longer. This battery alignment pattern works in different sectors to help customers adapt it to their unique requirements and needs.

The lithium-ion battery industry worldwide grows strongly at $182.53 billion by 2030 because parallel system development drives this surge and increases system capacity . Engineers need basic knowledge about lithium-ion batteries to face rising energy storage needs of higher capacity and better reliability across multiple user groups.

Our complete review explains basic parallel lithium-ion battery rules while reviewing other structures and showing their utility across industries plus studying their problems and looking at new ways to mix batteries boost performance. Our investigation shows how parallel lithium-ion batteries drive sustainable power solutions and electronic devices by overcoming issues of single-cell power limitations.

The Fundamentals of Lithium-Ion Battery Technology connecting batteries

In lithium-ion batteries electrical energy flows by enabling electrons through an external circuit as lithium ions shift from negative (anode) to positive (cathode) in an electrolytic solution. When charging the battery lithium ions travel back to the anode. Battery performance depends on lithium ions moving back and forth between electrode materials according to their rocking chair mechanism, like in one battery .

Each standard lithium battery cell combines four essential elements in its design including a lithium metal oxide cathode typically made from one of three possibilities (lithium cobalt oxide, lithium iron phosphate, or lithium nickel manganese cobalt oxide) and an anode built from graphite.

Lithium-ion technology leads other battery types because it delivers more total energy (150-260 Wh per kg versus 30-80 Wh for lead-acid), leaks minimal power when unused (3-5% monthly compared to 20% for nickel-metal hydride), shows no memory effect and works reliably for over 1,000 charge and discharge cycles. The lithium-ion power system outperforms other rechargeable battery types in all major electronic uses today, especially in terms of amp hours .

The output voltage of one lithium-ion cell ranges between 3.6 and 3.7 volts with variation depending on its materials composition. Lithium iron phosphate (LiFePO4) cells produce 3.2 volts less power than other cells but provide increased protection and longer lifespan. The voltage of two batteries in an electric cell results from the electrochemical difference between its cathode and anode materials.

Lithium-ion cell capability shows as ampere-hours (Ah) or milliampere-hours (mAh) measurements which represent the total power the cell delivers. Cell capacity depends on both the quantities of usable materials in the electrodes and the quality of the battery design, especially under different voltages . Today’s advanced battery cells store 250 to 680 Wh per Litre volumetrically which enables the production of lightweight strong battery solutions.

The lithium-ion cell uses controlled chemical reactions to work properly. During charging lithium ions exit the cathode crystal matrix to enter graphite layers between its layers as the anode material. During discharge, the process reverses. The electrode materials undergo thousands of reversible intercalation reactions without losing their performance, similar to the first battery .

Single lithium-ion cells have built-in safety components including vents for gas release during overpressure, thermal switches that disconnect power at high temperatures and some cells include electrolyte additives to resist flames. The separate safety features protect against thermal runaway by reducing the risk of a reaction speed up when temperatures increase, which can cause some cells to fail immediately .

Engineers who design battery packs for different uses must decide between cell series, parallel, and combination architectures to produce needed voltage and capacity levels. This choice affects both how all the batteries perform and handles safety risks yet increases how complex systems manage operations.

Series vs. Parallel Battery Configurations: A Comprehensive Comparison battery pack

You need to understand series and parallel battery connections to see why parallel lithium-ion batteries deliver special advantages. These separate ways of connecting all the cells produce battery systems with defined advantages and specific performance behaviors.

Batteries in series configuration connect in a straight line whereby positive terminals join negative terminals. When connected this way the batteries produce more voltage at their output without changing how much electricity the package can deliver. When placing three 3.7V batteries in series they would create an 11.1V battery pack with equal storage capacity as a single cell. Series connections help create batteries with higher voltage output which benefits power tools, laptop computers, and electric vehicles.

Every cell inside the chain connection receives exactly the same amount of electrical current. The battery cells generate higher thermal energy during operation when they possess elevated electrical resistance. When a cell in the series connection fails quickly it can receive charging energy from healthy cells which creates threats to safety. Series-connected batteries must use advanced monitoring systems since they need to keep the voltage of the second battery at an even level.

In parallel connections you bring together all positive terminals and all negative terminals. The parallel connection permits more capacity and higher current output without changing the single cell voltage level. When joining three 3.7V cells of 2000mAh capacity side by side will produce a 3.7V battery pack that delivers 6000mAh of power. The connective flow rate boosts up at an equal rate to let the battery pack send or take more current than what a single cell can handle.

All connected cells develop equal voltage output by nature. Connected cells with different electrical voltages will let a minimal current pass through until voltages reach balance. A parallel setup automatically balances battery voltages which eases monitoring work but it does not eliminate the need for cell maintenance.

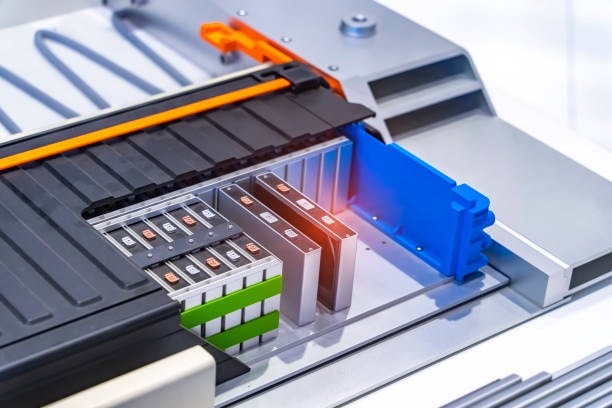

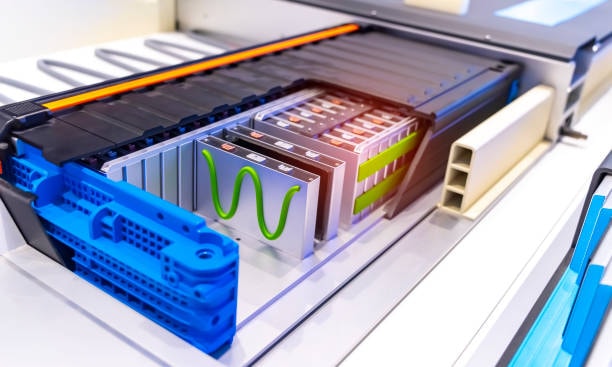

Different applications put multiple cell arrays in parallel that are later wired together in series groups for practical use. The setup offers both high voltage power requirements along with greater capacity and stronger electrical flows using parallel lithium batteries . Each group of parallel cells connects in series to boost voltage output and duplicates the number of groups creates more power. The connection system appears as 4S3P which means four separate series groups made up of three parallel cells each.

Deciding between series, parallel and series-parallel connections depends on the electrical demands of the application along with space constraints, thermal requirements and discharge current requirements. The selected configuration choices create unique strength and weakness balances regarding system design and battery handling.

Series battery packs deliver strong power but the entire system performs at the lowest output rate of its weakest cell. Parallel connections enhance battery reliability with backup power while enhancing current delivery through lower voltage cells. They bring better heat dispersion for applications where batteries endure high demand yet work with basic voltage needs.

How Parallel Lithium-Ion Batteries Work: Technical Mechanisms and Principles connecting lithium batteries

A parallel lithium-ion battery system connects the positive battery terminal ends and links the negative terminal ends to create a larger battery unit. The setup connects positive terminals to positive terminals and negative terminals to negative terminals to build one virtual cell with larger capability and increased current delivery.

A parallel battery pack delivers its total output load to all cells so that every element helps generate electricity. When batteries are connected in parallel the combined cells handle more power safely than solo cells do when they face high demands. Cells in parallel receive their share of total current based on individual resistance and energy level as required by Kirchhoff’s current law.

When electrically connected in parallel multiple cells function according to standard circuit laws. The parallel group of cells gives lower overall electrical resistance because its effective resistance equals the sum of all cell internal resistances divided by the total number of cells. A parallel series decreases internal resistance so the battery provides higher current flow with less voltage loss during operation therefore increasing efficiency and decreasing heat production compared to delivering identical total current with a single cell.

All electrochemical reactions take place within each cell in the parallel group the same way they function in an independent cell. When discharging the battery lithium ions move from graphite anode to metal oxide cathode to generate electrical power through the external circuit. When charging occurs external power moves lithium ions from the cathode to their original home at the anode. The parallel connection permits these operations to happen at the same time across various cells to distribute the workload equitably.

Using interconnected batteries in parallel brings additional protection to the system. When one cell in the parallel group stops working the other cells remain operational but produce less power. With parallel arrangement a system maintains power flow when one cell fails unlike series systems. With four connected cells in parallel mode the system still operates at 75% capacity when one cell experiences total failure because the other cells absorb the extra load.

When cells in parallel operate side by side they offset the common differences that naturally exist between cells. A parallel connection between cells adjusts the charge load based on each cell’s specific ability to prevent weaknesses from affecting the entire battery system performance. Lower-resistant cells take more power during heavy usage while capacity-rich cells send more energy during prolonged light load times.

Each parallel-connected battery in charging takes available current according to its internal resistance and energy level. Cells with low power levels take charge better than high-capacity cells which naturally equalizes battery conditions over time. Parallel cells use natural balancing as their key benefit even when cell matching remains necessary during production.

Parallel lithium-ion batteries show both useful and difficult effects when dealing with heat behavior. When multiple cells handle equal current portions throughout the battery pack they produce more effective cooling compared to a single cell passing the entire load. A faulty cell’s heat increases temperature which decreases its resistance making it draw more current, and threatens thermal runaway safety unless proper protection measures are implemented during manufacturing and product development and the cell adds to the overall risk.

The linking method between cells in parallel affects how the battery system performs. Devices with low electrical resistance need to be installed between cells to share power evenly and avoid wasted energy. Manufacturers construct parallel cell connections using metal busbars and join methods such as welding or soldering combined with special compression devices. Strong and dependable cell connections determine how well the entire parallel battery system operates.

Advantages of Parallel Lithium-Ion Battery Configurations lithium battery: Beyond Basic Benefits lithium batteries in parallel

Parallel lithium-ion battery arrangements serve many special functions that enhance their performance across many specific uses apart from their main strength in boosting capacity, ensuring that they can serve as the last battery option when needed .

Having more batteries than before presents the most recognized advantage. You can extend run times in devices by linking numerous cells together since the ampere-hour (Ah) capacity grows straight with the cell number while ignoring voltage demands. When joining four 3000mAh batteries in parallel the result becomes a 12000mAh battery pack that operates at its original voltage. System designers match capacity requirements directly to application needs by maintaining voltage-dependent components at the same levels battery manufacturer.

Better current handling ability represents the main advantage. Every battery in parallel helps deliver more current to power systems that demand higher power than a single cell can deliver single cell battery. A parallel battery connection delivers strong performance with high energy output demands including power tools drones and electric vehicle systems. The capacity of a parallel pack depending on the number of cells increases safely; a 4-cell parallel connection can output nearly four times more current than a single cell while internal resistance stays acceptable li ion batteries.

Parallel systems ensure better reliability thanks to their failure tolerance capability. In parallel setups one defective cell does not damage the whole battery pack since multiple cells operate while having lower power output. Parallel power connections offer natural defense against failures because they continue operating when one cell stops working properly batteries balanced. This benefit supports medical, safety and remote monitoring devices that need uninterrupted performance. The system slowly breaks down and presents maintenance opportunities before total failure happens same capacity.

A cell battery pack performs better thermally because its current load splits evenly among all cells. Since the total load power is divided among many cells the heat builds up evenly across the entire battery pack which helps ensure longer operating life by averting hot spots. Having heat spread across many cells lets us cool better and prevents unexpected battery overheat issues. A battery pack with parallel cells shows continuous performance by letting one cell reduce speed to keep cool solar panels.

You can achieve better cycle permanence with a parallel battery setup compared to running one cell at its highest output rate. Smaller stress loads on each cell during parallel operation help slow aging processes and increase the total battery life span. Minimal lithium-ion cell use at rates below their capacity (lower C-rates) preserves capacity better than high-level C-rate operation according to research data. Parallel cells handle lower discharge rates than what a single cell would sustain to deliver the entire load green energy.

Parallel placement helps the battery system better receive charging power. A group of cells connected in parallel handles larger fast charging currents evenly among all cells. Cells in parallel can accept higher charging power than singles cells which means battery-powered tools spend less time charging safely. Equipment that requires fast charging such as electric vehicles and industrial machines benefits from parallel configurations because it enhances their operational performance special charger.

Parallel setup designs enable builders to position battery packs easily into specific areas. Using sets of smaller battery cells helps designers create battery packs that match irregular forms and slip into tight areas. Battery designers appreciate this geometric freedom when they need to fit electrical power elements into portable devices or space-restricted industrial devices voltage difference.

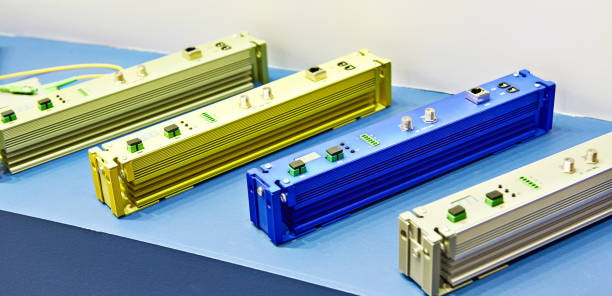

The technique delivers cost savings when it lets designers select economy-packaged cells to replace custom large-size cells. Manufacturing basic cell styles (such as 18650, 21700 or prismatic types) at scale becomes cheaper than producing specialized cells per unit. This also lets users replace any failing cells with brand standard replacements.

Applications Benefiting from Parallel Lithium-Ion Configurations: Industry Solutions battery manufacturer

Parallel lead-acid battery systems provide reliable power delivery across many different fields whenever significant electric charge and current levels are required.

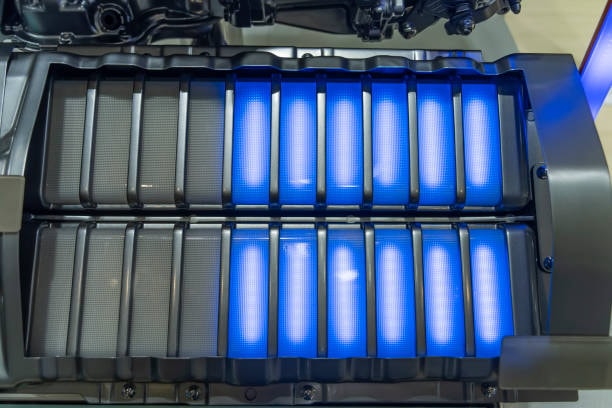

EVs are one of the main fields that benefit from parallel lithium-ion batteries. EVs today use battery packs with thousands of arranged cells wired both in series and parallel to store power. The series-parallel connection system lets the battery handle increased power consumption for best performance during rapid acceleration. Each Tesla vehicle contains many cylinders of cells lined up parallel for grouping and then joined in series to create the needed high voltage. The method uses multiple cells to create safety layers that enhance temperature control. By grouping cells together the power system stays stable since degraded cells in one area affect just a small part of the overall capacity. The three rows of battery cells in parallel enhance fast-charging efficiency because the charging power spreads evenly among all cells.

Parallel connections provide many benefits when used with renewable energy storage systems. Solar and wind energy systems demand large energy storage units known as battery banks to capture their peak power production moments which they later transfer when power generation slows. Lithium-ion batteries arranged in parallel deliver full power capacity plus system redundancy essential for important infrastructure operations. Energy storage systems at grid level connect multiple modules in parallel that service providers can swap while keeping the entire system online. Our systems can automatically expand their power storage capacity through adding more linked battery units for future requirements. Parallel setup’s strong power output capacity helps performance control grids better when power systems with many renewable energy sources face quality problems.

High-current consumer electronics need batteries installed in parallel arrays. The electronic components of powerful gaming computers and professional camera devices alongside high-performance tablets require parallel cell arrangements for managing sufficient capacity and current usage with proper power levels. Smartphones with powerful batteries connect several cells to create a thin model that gives users enough power for an entire day. Advanced video tools depend on parallel batteries to provide consistent high power for their high-tech components that maintain perfect voltage and avoid performance drops.

Portable life-support medical devices put two batteries in parallel to keep systems running dependably and extend battery life when patient safety matters most. Getting power from two independent batteries helps medical devices including ventilators, infusion pumps and monitors maintain proper functioning during blackouts and mobility. Despite offering two power sources our parallel setup gives medical devices a reliable backup system they need to function in critical situations. Medical devices put inside the body need grouped micro-scale cells for longer operating time plus short-term boost capacities needed in treatment like cardiac defibrillation.

Parallel lithium-ion systems supply power to both industrial equipment and UPS systems to deliver backup power during grid failures with high capacity and current output necessary to protect sensitive equipment. Data centers depend more often on lithium-ion UPS systems with linked battery cells to keep their critical systems running when utility power fails. The speed and high power output of lithium-ion system setups ensures defense against any brief power fluctuations that can hurt valuable server equipment.

The military and aerospace industries need parallel lithium-ion arrangements for important applications. Using several lithium-ion cells in parallel favors military portable power systems as well as UAVs and satellites because this setup creates reliable backups and more powerful energy supplies. Parallel systems in space applications prove essential because damaged instruments have no option for fixing or replacing on deployed platforms. Field equipment in the military sector features parallel lithium-ion power systems to decrease weight and support extended operations with peak performance for communication and combat systems.

Lithium-ion technology systems run boats parallel to their house power system and work effectively in all marine vessels. Lithium-ion systems can save weight due to their high energy density and their parallel design provides backup power in marine environments that require it. Parallel lithium-ion battery setups improve boat propulsion performance and range since they offer high currents and longer runtimes.

Parallel lithium-ion battery systems serve as backup power systems required for telecommunications facilities that include remote cell towers and network equipment. These facilities must run with great stability for long periods of power loss at temperatures that can be extreme for their environment. The way lithium-ion batteries arranges in parallel brings together backup capacity and robustness while operating better in temperature conditions compared to other batteries.

Parallel battery setups match the power needs of portable performance tools including scientific tools by supplying large battery capacities and fast power delivery at once. Special application demands push for both long-lasting yet high-current battery support which parallel technology addresses effectively.

Design Considerations for Parallel Lithium-Ion Systems: Engineering Challenges

When creating parallel lithium-ion battery systems you need to focus on design elements that link to their safety performance and life span. technical people solve many technical problems while building advanced solutions that handle these design aspects.

The choice of suitable battery cells matters most among all system components. Parallel-connected batteries need to perform with tiny differences between them for highest efficiency. Manufacturers use cells from single production batches so that mismatched cells do not cause current imbalance and early cell degradation. Advanced manufacturing plants use automated sorting systems that check multiple features of cells to put very similar units into parallel groups. The regular aging process of cells makes their performance differ over time despite effective matching procedures at start.

As the number of parallel cells increases so does the need to manage their temperature effectively. Parallel-loading systems create significant heat in their operation especially during periods of high current flow. Good systems use heat sinks paired with active cooling or phase-change materials to keep the battery pack at its ideal working temperature. Temperature sensors at key locations in the pack give data to the battery control system to tweak both the heat removal system and power handling limits to stop overheating in specific areas. Special battery designs include separate channels to carry heat out of each cell or fill space between cells with electrically insulating fluid that conducts heat well.

The present solutions to balance power distribution evenly between cells maintain the system’s expected performance output. Parallel connections distribute power evenly but little differences between cell resistance creates poor current flow. Advanced battery control systems watch each cell performance and automatically shift power through balanced channels to equalize cell energy use. These designs add resistance detectors in parallel branches to track how power divides among cells before imbalances indicate battery state changes. The active circuit design directs battery current where it needs to go to keep electric power spread evenly between all cells.

The protection circuitry defends against hazards including short circuits, battery drains to zero and excessive charging voltage. Every scenario in parallel connections demands specific protection methods to handle its special needs. Current systems feature backup protection features that prevent dangerous situations when one component breakdown occurs. The PTC devices or fuses in every parallel section enable the detection and isolation of failing cells or sections when an issue occurs. Protection systems consist of several layers to monitor voltage and current levels plus analyze conditions to avoid dangerous failures.

Physical layout and interconnection design significantly impact system performance. Connections with low resistance between cells reduce power waste and proper physical organization helps maintain good temperature control. Engineering teams need to examine how connections handle mechanical strain when the devices operate normally plus handle vibrations and shocks seen in mobile setups. Busbars for parallel connections include large cross-sections to lower resistance levels and resist mechanical stress. Our team selects from available connection techniques like laser welding and ultrasonic welding technology when each cell system needs demand and operates under its unique environmental conditions.

Quality design aims to keep the cells in their correct position and secured from start to finish during product use. The cells in charging and discharging activities plus temperature changes create mechanical stress that weakens connections until they fail. The cell holder and retention system should position cells securely and still handle their small size changes while delivering heat for cooling. Applications that experience jolts and vibrations need additional support and shock reduction measures to protect cell connectivity and avoid battery damage.

Separating electricity between cells and external parts is necessary for safe operation and operation effectiveness. Quality insulators between different cell packs and the battery housing block undesired electrical paths from forming a shortcut around safety controls. Advanced monitoring systems check whether electrical isolation between battery cells remains secure particularly when working with high-voltage batteries due to safety risks.

Ideal system design requires engineers to examine possible battery failures and their effects while working on parallel battery storage units. Engineers need to study all cell fault scenarios to design proper protective measures suitable for ensuring system safety. Our assessment shows the requirement to build material walls between cells as well as structure heat bursts prevention steps that can divide the battery suite into parts.

To create reliable parallel battery systems you need to control both manufacturing steps and assembly operations. The automatic and partially-automated assembly procedure checks product quality during production to find defects earlier. After production we verify capacity and check internal resistance with heat mapping and protection system failure operations.

The need to follow regulatory rules affects parallel lithium-ion battery system design because each product type and geographical market features different standards. Transportation regulations, safety standards, and end-of-life recycling requirements all influence design decisions for parallel lithium-ion battery systems. All test outcomes and safety analysis documents help parallel lithium-ion battery systems follow multiple regulatory standards.

Battery Management Systems for Parallel Configurations: Intelligent Control

Battery Management Systems (BMS) help parallel lithium-ion battery setups work better and safer through their performance optimization technology. Electronically advanced systems monitor the battery functions and modify these controls to ensure safety under all operating conditions.

A good BMS system manages parallel battery configurations by performing multiple necessary control functions. It checks cell voltage levels to keep each battery from causing damage during operation. Parallel setups let you monitor fewer cells since linked cells automatically balance at the same voltage point. Advanced BMS monitoring systems check multiple battery group voltages to identify potential connection issues and cell problems that are not noticeable from their group average voltage.

In parallel designs the BMS needs to track and control how current flows between each battery cell to prevent over-imbalance. State-of-the-art BMS technology includes sensors at each parallel group to detect if a cell cell is failing or has a connection problem. The BMS uses real-time data from hall effect sensors or shunt resistors to see how current moves through the battery system which helps it predict problems before they become severe. Complex systems include sensor groups that detect how each cell element affects the parallel connections.

The main BMS function is maintaining optimal temperature control for the battery. The system uses temperature readings from different battery areas to initiate cooling functions and limit power output to avoid overheating. A parallel battery system needs equal temperatures across all cells to make sure they operate at the same level. The BMS detects problems in the battery pack and cooling system by using its temperature sensors that monitor all areas to generate thermal maps. Temperature readings from the BMS help manage active cooling systems and controls how energy flows into and out of the pack before initiating shutdown at risk thresholds.

The BMS helps operate battery cells better by showing users their precise battery capacity to manage charging and discharging steps well. In parallel battery setups the BMS needs special algorithms to track how several cells work together in one connected system. BMS technology uses different measurement methods such as coulomb counting to track battery charge flows combined with open-circuit voltage reading and impedance monitoring for precise SoC prediction across all operating conditions. Modern computers assist battery management systems by uncovering regular cell behaviors that match certain power storage levels.

Through communication BMS sends measured values to outside systems and accepts control information from them. The system links up with advanced power controls and monitoring systems for vehicle and storage functions. The BMS system communicates through standard technology connections including CAN bus, Modbus, and custom setups. Cloud connectivity in modern BMS designs lets you get advanced functions that predict when parts need work plus send updated control parts to all batteries from the cloud.

A BMS should balance cells even though this function matters less to parallel circuits than to series configurations. Although cells in parallel connections tend to stabilize voltage automatically the BMS needs specific methods to distribute charging current evenly among all cells. Active balancing equipment moves charge from one parallel group of batteries to the next to make up for how cells differ as they age.

The BMS functions of fault detection and protection stand as the essential requirements for lithium-ion parallel systems. The BMS reads voltage temperature and current data continuously to discover electrical issues before they progress to severe problems. After finding developing issues the BMS takes several stages of coverage steps starting from lowering acceptable current levels up to separating faulty sections or fully stopping the system operation. Several protective systems work together to detect and respond to external shorts, cell failures, charging and discharging faults plus thermal issues.

Protection solutions that manage thermal issues make up a vital part when designing and running multiple battery arrays in large energy systems. The BMS tracks important thermal behavior indicators such as voltage problems and temperature surges along with changes to cell resistance that predict degradation. When indicators show a battery issue is coming the BMS protects the battery by disconnecting affected sections and starting emergency cooling or fire suppression actions depending on system needs.

Advanced BMS controllers collect system data to find better ways of running the battery system and fix possible issues. Watching how the battery behaves during use reveals patterns that both show when damage is starting and point out methods to enhance power output. The system keeps providing useful information that supports warranty claims and helps designers make battery upgrades.

BMS tools connect external data to clear indications that operators can act upon. The BMS system can show basic charge status plus full performance readings or notify users about needed service plus reveal the power remaining based on present utilization rates. Different user interfaces handle battery system information in ways that match how the system is used from basic LEDs on personal devices to advanced grid storage and electric vehicle displays.

Challenges and Limitations of Parallel Lithium-Ion Batteries: Critical Constraints

Parallel lithium-ion battery systems have benefits but engineers must deal with important operating challenges to build safe and effective battery solutions. Viewing battery configuration limits helps us create better protection measures and use parallel strategy correctly.

Balanced cells remain the main issue for parallel lithium-ion battery designers. No matter how thoroughly matched cells change from their original performance after a period of use. When cells do not perform at the same level problems arise with current distribution that can overwork some cells and speed up their break down. When cells age at different rates they increase their internal blocking effect and lessen their power input during discharge periods. The unequal aging process between battery cells decreases total parallel group performance and demands special management or replacement of affected cells.

Fault spreading represents a significant threat to operational risks. When one cell develops a fault it draws more power from all its parallel relations until thermal runaway breaks out to all connected cells in the pack. Series connected cells only fail open but in parallel systems when one cell fails the damage spreads across all cells. Thermal runaway presents an added risk because one overheated cell can move down each connected battery pack unit and push those cells into stability threshold temperatures. Controls and defenses that isolate circuits and stop issues quickly need to be added to parallel battery systems to reduce this danger at a higher total cost.

Parallel system design causes extra challenges to monitoring procedures. Monitoring individual parallel group cell voltage requires advanced BMS hardware and software making the system more expensive and complicated. Regular battery management tools that depend on voltage readings show decreased accuracy when used to find issues in parallel arrangements; more sensor types must be added. To monitor current consumption in each part of the parallel branches needs more hardware and adds complex wiring. Also monitoring temperature requires advanced detection capabilities to spot separate heating in each cell of parallel groups.

The setup challenges in parallel arrays become more difficult as the number of parallel groups increases. Enlarged cell parallel networks become harder to balance while protection systems need stronger fault current capability and cell temperature control becomes complex. The multiple connection criteria limit how many cells can work safely without additonal protection systems. Parallel groups of cells that carry a large amount of potential energy create safety dangers when electric faults occur because they generate very high fault currents quickly. To make useable battery systems most designs divide their parallel connections into smaller groups which are combined in series.

Maintenance and serviceability present ongoing challenges throughout the system’s life. Replacing a single cell in parallel group formation proves hard because it affects all the remaining cells. The design poses severe problems when non-stop power is needed or the battery system cannot be easily accessed. Faulty cells in a parallel group need complete module replacement because individual cells cannot be fixed effectively. This maintenance strategy quickly builds up costs while forcing users to end the life of partly working battery systems sooner. Investment-grade battery systems include hot-swap technology in small cell sections but these elements create more complexity and may develop issues.

Cell connections constantly breaking down creates a significant problem for users. Cells need their weak electrical bonds to work well but these bonds become damaged by temperatures shifting, physical movement, and metal degeneration in certain conditions. More resistance in connections causes unequal current spread that leads to faster component breakdown through heat buildup. The right connection methods including laser welding and compression fittings lower failure risk but require continuous monitoring and upkeep for missions with harsh environments.

Power systems with multiple parallel strings are harder to cool especially in systems with heavy current flow. Managing heat production evenly in multiple cells without proper thermal design worsens both cooling flow and heat movement issues. The thermal design needs to handle all expected system conditions because some cell failures could produce unusually high heat levels. Advanced temperature control systems increase product costs and manufacturing difficulty but use energy that lowers system performance effectiveness.

The protection components of a parallel battery system place technical limits on its performance. The rapid protection devices must receive proper sizing adjustments to protect under fault scenarios but avoid disrupting normal high-current procedures. Additional protection gear becomes needed when parallel battery groups become bigger because they face greater fault current risks. Protection systems should reply fast enough to save battery hardware from damage yet stay clear of accidents that will turn the battery equipment off.

Technical and environmental problems come together as batteries approach their final stage. Parallel battery packs show faster changes in cell qualities that force them to get replaced at the end of their lifespan. Cells in parallel groups connect very closely which makes picking out specific ones for recycling hard and the many connections create challenges when automating the disassembly process. Teams worldwide explore new ways to recycle parallel lithium-ion pack batteries as their research proves decisive for expanding their use.

Parallel lithium-ion battery structures create difficult compliance problems because of their many failure modes and great energy storage capacity. Government transportation rules demand intense battery quality checks along with proof of operation for lithium-ion batteries but they inspect parallel battery setups even more rigorously because of their bigger capacity and energy usage. Parallel battery systems need to follow safety protocols that make them more expensive to manufacture especially when used in aircraft and controlled sectors.

Innovations in Parallel Lithium-Ion Battery Technology: Cutting-Edge Solutions

Researchers develop parallel lithium-ion battery technology effectively at high speed by fixing current problems and creating new application fields. The latest research focuses on battery materials science as well as control systems for thermal management and total system optimization.

The research on improved cell-balancing methods shows great promise today. Recent techniques now track battery impedance and measure how current flows through the system as it operates. Improved sensing technology finds underperforming cells better for equal distribution among parallel groups of batteries. Smart battery controls automatically shifts power distribution to protect cells from unequal wear so the entire system can operate longer. Modern battery technology includes active balancing systems that direct energy between multiple branches to correct this change while the battery is operating.

Smart fault control systems are making important updates to parallel setup operations. These systems detect cell or subgroup problems early when they start so pack failures remain small. Both new products and semiconductor switches respond to fault detection in less than a millisecond to enhance safety while maintaining standard performance. Fast-acting electronics block fault currents when they start to harm cells by isolating affected units. These advanced systems track cell performance signs that indicate future failure and help experts isolate cells before genuine failure happens.

Wireless monitoring technology makes it easier to track the performance results of each cell in parallel groups simultaneously. The system design lets the BMS gather full power measurements from every cell by getting rid of physical links to the main processor. Emerging technology uses tiny wireless sensors to detect cell temperature, voltage and in some cases gas pressure that then sends data to a main system headquarters. Reduction in complexity during manufacturing makes this approach more reliable since connections between parts can fail over time. Wireless sensors can draw power directly from battery energy in specific designs using energy harvesting methods.

The new thermal optimization techniques work to make temperature levels of multiple battery packs in parallel match each other. Companies develop phase-change technology to store heat during intense usage plus build microfluidic paths and thermal conductors to even heat spread across battery packs. Cells surrounded by non-conductive thermal transfer fluids become a powerful solution for demanding electrical systems. Extremely powerful batteries stay operable at high output because direct refrigeration removes thermal buildup between cells. Research tests show how active heat removal from hot battery areas happens through thermoelectric elements placed inside the battery pack.

Artificial intelligence systems bring the biggest possible improvements to parallel battery power management. Machine learning examines cell behavior data to detect failures early while optimizing power flows by automating usage pattern navigation and service strategy updates. AI systems that track fleet-wide data and monitor separate battery systems daily get smarter by learning new ways to predict and adjust operations. Informatic systems now take complex battery diagnostics and convert them into easy-to-understand operator recommendations while reinforcement learning techniques update their performance management techniques from results.

Research facilities now develop cell chemistries that work better in parallel applications. Research teams work to produce cells that show minimal performance variation during manufacturing while keeping their age-related performance fluctuations low. Engineers design silicon-graphite composite anodes to expand evenly during charging which alleviates physical strain that impacts battery lifetime difference between cells. Innovative electrolyte solutions use special additives to produce solid-electrolyte interphase (SEI) coatings across all battery cells which minimized performance variances between units.

New packaging solutions help manage the mechanical and thermal problems in parallel battery setup. Structural battery designs use cells as load-bearing elements which saves space while creating efficient thermal paths through components. These advanced designs monitor temperature changes to apply equal pressure on battery connections and keep electrical contact stable from start to end.

Hybrid power storage setups pair parallel lithium-ion batteries with supercapacitors or batteries of different lithium-ion chemistries to achieve optimal performance. Parallel lithium-ion batteries with powerful cells handle both normal battery capacity and short-term load requirements. The main parallel battery group handles lighter loads more often to lower the electrical strain and increase its lifespan despite remaining able to supply necessary power. A smart system controls power share between the storage types according to present power needs and battery conditions.

Self-healing materials and connection systems solve the main battery connection problem that affects parallel battery systems over time. Materials with self-healing properties let conductive polymers fix electrical pathways once mechanical damage happens and special coatings shield connection points from growth of resistive oxides and rust. Experimental battery setups use liquid metal connections that keep electrical contact stable during thermal expansions and contractions. Technology improvements work best when installed in devices that handle shaking motions or experience intense temperature shifts.

New diagnostic systems help companies better maintain multiple lithium-ion devices. EIS tests conducted during system operation capture cell changes before they create operational problems. Acoustic monitors detect small cell structure changes that lead to problems ahead of time while thermal cameras using affordable high-quality lenses spot details about connection and cell issues without physical contact. Quality diagnostics help us switch from fixed replacements to failure-based upkeep which saves life costs and works better.

The entire battery sector now works together to develop shared solutions focused on parallel battery technology. The standards recommend ways to connect battery packs while defining essential safety steps plus heat handling procedures and data exchange methods which decrease product interfacability workloads and development expenses. Standards development works toward regular industry innovation by adding safety and performance rules for all participants.

Future Directions for Parallel Lithium-Ion Battery Systems: Emerging Horizons

Parallel lithium-ion battery technology nears significant changes that will improve power storage for various industries. Emerging energy storage techniques help us overcome present limitations by creating new possibilities that did not exist before because of battery storage restrictions.

Solid-state lithium batteries are expected to deliver the most important new technology advancement. These batteries switch from liquid electrolytes to solid materials which brings benefits of greater stored energy with better safety and durability. Switching to solid-state batteries enhances parallel systems by making these batteries safer against thermal issues and helping producers fit more capacity into smaller space units. Thanks to lower risk of chemical leakage and gas emissions from defects solid-state cells prove better suited than other options for large cell arrays where protecting failed cells is complex. Pioneering businesses use specialized equipment while growing manufacturing will bring battery technology to mainstream use in the next 5 years. Improved thermal protection and cell uniformity create opportunities to expand parallel groups with simpler monitoring systems than before.

Multifunctional power extraction systems will pair with parallel batteries in wearable tech and remote sensors soon. Small solar power, kinetic energy, or heat sources integrated directly into battery packs would recharge power during use to make batteries last longer. Parallel battery systems offer direct connectivity to energy harvesting units because these setups do not need advanced balancing circuits. The system delivers its best results for Internet of Things devices and environmental monitors in distant areas where normal battery replacement is out of reach. Researchers have put flexible solar cells directly onto battery pack surfaces to create an independent power system for minimal power needs.

Building batteries directly into renewable energy systems makes a promising way forward especially for grid electricity storage. Future parallel lithium-ion systems will include separate battery cells created to react quickly to grid frequency shifts and other cells built to deliver long-duration power. The integration of specific roles into one battery system improves effectiveness at lower total expenses than installing separate batteries for each use. Recent solar/battery technologies use DC coupling to eliminate conversion waste and make system design simpler. Several virtual power plant initiatives that collect individual battery clusters from multiple sites can create reliable energy networks that adapt well to changing conditions.

People focus more on recycling and reusing lithium-ion batteries because the first generation systems require replacement. The way batteries stack side by side in parallel setups creates chances forLate Life Usage by redistributing cells according to their saved performance. This method helps lithium-ion cells serve customers longer without hurting the planet. Special machines are now available to check used cells and place them into groups for specific reuse purposes after complete test results. Companies and governments create new guidelines to handle battery reuse challenges including safe product authorization and legal protection practices.

The lithium-ion system industry works towards making all manufacturers use common safety standards and ways to connect devices. Companies can save time and money while researching cell technologies when systems follow common requirements for connection and interface. A single battery module design with standardized electrical and mechanical parts can simplify maintenance of the entire energy system. Researchers sharing open-source battery management system designs lets them create better optimization methods and testing methods that speed up system improvements.

Parallel lithium-ion systems require bidirectional capabilities more than ever because companies use them to connect vehicles to the electric grid and power homes. These systems both retain stored power for use later plus feed power back to both electricity grids and secondary equipment when financially viable or during power outages. Parallel system architecture delivers strong power outputs that work best in applications needing quick power transfer. Advanced bidirectional converters increase system performance at lower error rates which makes these systems safer to use according to updated grid connection rules.

AI systems monitor parallel lithium-ion systems to help extend their reliability and lifetime value. The analysis of battery pack performance over many systems helps artificial intelligence systems discover minor failures early when regular tests would detect them. The systems use predictive analysis to suggest specific actions that keep the systems running without overspending on replacements. Advanced systems work with digital twin software to keep electronic models of their battery systems filled with real performance data. They use this information to both update their predictive tools and refine their management techniques.

Modern production methods help companies manufacture parallel battery systems better. Automation systems designed to change automatically produce different versions of parallel battery cells that match various packaging forms and electrical connections through digital blueprint input. Our flexible production system lets us create customized battery solutions for customers without losing the cost benefits of efficient large-scale production. Our quality control methods check electrical impedance and thermal images of each system during assembly to make cells that work the same in all products.

The development of quantum dot and nanomaterial technologies helps solve major problems in parallel lithium-ion cells. Advanced materials establish a regular lithium ion transport path that helps parallel batteries operate without issues. Experimental materials can repair battery electrodes during usage to create batteries with better parallel performance as they age.

Energy-efficient methods to produce lithium batteries and reuse spent materials help solve sustainability issues due to rising battery material needs. Scientists create new extraction solutions with low environmental effects as they develop ways to extract and reuse more critical materials from old batteries. Lithium-ion developments ensure more batteries reach the end users who depend on them. Many areas now regard building battery material supply chains at home as their main strategic focus which leads them to invest in mining and battery recycling facilities.

Conclusion

Modern energy storage systems depend heavily on parallel lithium-ion battery setups which give us benefits with power supply volume and current strength alongside battery backup and heat dissipation control. The need for parallel battery systems in various industries will increase as we need these systems more to store energy in electric vehicles and improve the integration of renewable energy systems. These arrangements help power applications when single cells or series assemblies alone cannot deliver enough capacity and current.

Preventing parallel lithium-ion connections requires knowledge of basic electric circuits plus detailed comprehension of cell electrical and heat reactions. When you link several cells through their positive and negative terminals parallel circuits turn them into large-capacity units giving you more power for your needs. Connecting batteries in parallel distributes power usage which strengthens reliability and life span if done correctly.

Many industries all over the world use parallel lithium-ion designs in their operations. Customers need electric vehicle batteries connected in parallel to deliver both driving distance and power levels they want. The energy systems store both wind and solar power through parallel-connected batteries as reserves for times when electricity generation levels decrease. Different types of electronics devices depend on parallel batteries as their basic power systems including medical equipment, medical devices, automobile powertrains, industrial production machines and aviation systems. Different organizations continue to use parallel battery connections because they demonstrate big benefits across many types of applications.

Designers still struggle to create high-performance parallel lithium-ion systems. The design teams have to solve thermal management, safety protection, battery cell matching, and monitoring difficulties to make parallel lithium ion systems work effectively. Battery management systems address all major battery issues by monitoring performance while protecting and optimizing battery operations during its life span. These battery management systems keep improving by adding intelligence features for better maintenance prediction and wireless performance tracking.

Research teams solve these issues at present by working on improved material science and battery monitoring systems through advanced management algorithms. The combination of advanced connection controls with wireless tracking data plus smart temperature control uses artificial intelligence to produce better parallel lithium-ion battery systems. The new developments in parallel battery systems enhance their usage areas and make them more dependable over time.

Parallel lithium-ion battery technology brings great prospects for future development. Solid-state battery technology could help solve safety problems of lithium-ion batteries while making energy harvesting available for mobile and off-grid electronic devices. Renewable energy connections plus distributed standardization and harmful waste reduction create eco-friendly storage solutions for parallel lithium-ion technology.

Every industry shift toward clean energy and electronic expansion will rely on parallel lithium-ion batteries which maintain their essential role as advanced power storage units for present and future applications. Ongoing work on these power solutions will help solve world energy problems and unlock new use cases that require dependable portable energy.