Meta Description: Find out how to securely tame installed shutoff solenoid fuel shut-off solenoids in engines, tractors and heavy machinery with safety tips. Skilled handbook deals with troubleshooting, problem solving, potential safety hazards, techniques for using a rubber tip, and trade repair tactics to equipment operator alignment lists.

The next time your gear fails to power up because of the bad fuel shut-off solenoid, the ability to bypass this vital part may be the difference between business-killing down-time and getting to work two wires. The fuel shutoff solenoid is a vital position of the safety element in engines, diesel machinery and lawn care equipment to maintain fuel circulation to an engine to eliminate hazards like runaway diesel or backfire during shut down.

All that the fuel solenoid does is to close off fuel when closing the engine so that the engine cannot backfire when it is turning but the ignition is not still on because the vacuum is pulling fuel. Nevertheless, in case of failure of this component, it is very important that the operators of equipment and mechanics together with users of the heavy equipment know appropriate methods to prevent fuel and bypassing the carburetor component work fine.

This guide will dwell upon the safe and efficient ways to bypass fuel shut-off solenoids with highlighting and stressing the safety procedures, the integration of the gas line, and long-term recommendations. Still talking about lawn mowers, tractors, diesel engines, or construction machines, this post offers the technical information and practical guidelines that can be used to solve solenoid failures related to motor operation plunger .

GWT Worldwide We are a worldwide logistics services provider that knows how crucial equipment reliability can be in our operation. Being a professional provider of logistics services utilizing air, sea, China-Europe railway, and customs clearance services, we understand that the loss of time of the equipment may strongly affect the ground efficiency of supply chains and customer satisfaction at the other terminal .

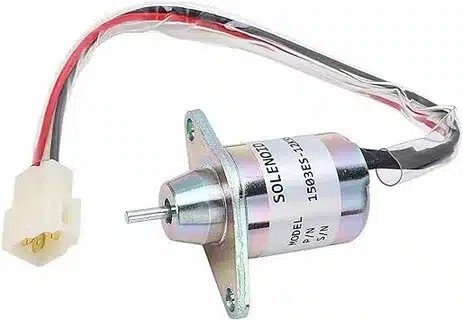

Understanding Fuel Shut-Off Solenoid Function and Common Failure Modes fuel shutoff solenoid

The fuel shut-off solenoid is used as an electromechanically switched valve to control the supply of fuel into the combustion engine. A fuel control valve is usually solenoid operated, which is normally closed (NC). It has to be opened using high current electrical current. This normally-closed coil circuit is also defined so that when the electrical system is de-activated the wires ensure that fuel is not able to flow that ensures a fail-safe situation on the shutdown of the engine.

During new equipment, fuel shut-off solenoids are adapted to complicated safety systems controlling numerous working parameters. Such systems commonly have seat switches, parking brake interlocks and power take-off (PTO) safety circuits. In case any of these safety conditions are failed, the terminal solenoid instantly disengages the flow of fuel and thus any accident or damage on the equipment is evaded.

Sudden engine shutdown during operation, failure to start under reasonable fuel supply levels, hitch hikes in the engine behaviour and total loss of power under important work are normal symptoms of problems in the fuel shut-off solenoid. Some symptoms of a faulty fuel solenoid include sudden engine cutoff, switch tripping and engine stall. It also has the ability of disengaging the fuel pump and this condition could be summed up as a no-start thinking in that it will not allow ignition of the engine.

The electromagnetic coil in the solenoid may be destroyed by many aspects which may include; electrical overload, moisture infiltration, mechanical wear or by stress heat caused by continuous use. The internal springs could wear off with time and fail to close the valves or alternatively open them. Fuel degradation can also lead to destruction of tank valve seat or debris build up interfering with normal operation and possibly affecting the float bowel .

Testing Electrical testing is usually done with multimeters to test coil resistance and coil continuity. Diagnostic information as to the physical inspection of fuel leaks, corrosion, or stretch marks can be provided by visual inspection. The solenoid valve housing should be inspected to check any physical damage, as well as, fuel leakage. Also, verify the circuit connections between the solenoid valve and make sure that there are no disconnects, looseness, and short circuits.

The knowledge of the solenoid and what it does to the overall management of the engine allows the operator to decide about the bypass procedures in an informed manner. Integration of the component with other emission control systems, fuel injection timing and safety interlocks imply that bypassing should only be taken as an emergency situation temporary solution but definitely not a lasting solution.

Failure of solenoids in vital equipment will cause downtimes, which may domino to other operations. In the farming environment, malfunctioned solenoids during the harvesting period may lead to great losses. In case of construction equipment, the failure of the solenoids may stop the project deadlines and raise the working hours. In logistical purposes such as those performed by GWT Worldwide, a failure in equipment reliability will result in direct effects on delivery schedules and customer promises.

A preventive maintenance program must incorporate periodic inspection and test on solenoid to isolate pre-failures before they lead into shutting down of equipment. Moisture should be avoided by cleaning electrical connections and fuel system maintenance to avoid contaminants that were capable of damaging solenoid parts, particularly when not using a jumper wire .

Costs of Solenoid Failure Its economical cost hits far beyond the initial repair costs. Lost efficiency, emergency service request, risk of safety incidents are other costs that could be mitigated using adequate maintenance and awareness of a bypass process in case of an emergency.

Safe Bypass Methods and Emergency Procedures

In case of such a field situation of having failed fuel shut-off solenoid several by-pass ways of restoring the functioning of the equipment can be implemented at a reasonable level of safety. The simplest one is mechanical bypass where a set of fabricated parts are connected to act as the valve instead of the solenoid.

Required : 5/16-24 Bolt and Nut o ring Top plug to the bolt 1/2 Wrench First you are going to remove the fuel shut off solenoid with a 1/2 wrench Second you are going to take a 5/16-24 fine thread bolt with the nut and screw it on and tighten it down Third you are going to place the bolt to the vise and cut off the bolt and then grind flush with the nut. This mechanical by pass technique provides a permanent fuel paradigm that substitutes the variable flow control of the solenoid.

in carburetors all you need do is cut off the end/tip of the solenoid. It assists in avoiding the backfire when you rev down the motor a little letting it cool down before turning it off. This straight forward change eliminates the needle valve in the solenoid with leaving the mounting arrangement the same as the original. The drawbacks of this however are that the ant backfire protection offered by the solenoid is removed.

One are more advanced method of bypass is the inclusion of a manual fuel valve in the fuel line in front of the place of the solenoid. One way that can be thought about when it comes to a faulty fuel shut solenoid is to bypass the fuel shut solenoid and instead fit a valve to the carburettor fuel inlet line. First of all, tighten the valve in a safe manner and, then, close it. This process maintains manual control over the fuel flow against non-requirement of electrical solid operation.

In diesel engines with the injection pump solenoids mounted on it, the often used mechanical bypass is the solenoid body itself, where one gets to the internal linkage apparatus. A person can get it off and the engine will stat, but you might need to reach in the hole, and push the linkage to shut the engine Off. In this process, shutting down the engine involves a manual control of engine fuel needs.

The electrical bypass techniques emphasize on the steady flow of electricity to the solenoid coil that compels the coil to be in the open position at all times. Just tape the solenoid wires out of the way so that they could not get inadvertently grounded. This helps avoid unwanted closure of the solenoid, and also keeps the voltage electrical circuit intact to other systems, as suggested by forums top contributors .

In the case of applying bypass procedures, tools and safety equipment must be selected properly. Such fundamental hand tools as wrenches, wire strippers, electrical tape and cutting devices must be easily available. When fuel system modifications are carried out, safety goggles, work gloves and fire extinguishing devices are used.

Their step-by-step bypass work is supposed to start with the shutdown of an engine and depressurization of the fuel system to avoid spillage and fire risks. Any electrical systems need to be disconnected so that the solenoids do not get activated accidentally upon modification work. All connections of fuel should also be well labeled and photographed to allow proper reassembly after disconnection.

Emergency bypass conditions involve uneven evaluation of the materials and tools that are at disposal. The field repairs can reduce to improvising hardware based on ready availability but the safety should never be sacrificed. The temporary bypass diversion techniques must also be tagged and labeled to make proper repair when proper replacement components have been received, which can be visually confirmed in an image gallery .

Recordkeeping of bypass activities enables the maintenance personnel to familiarize themselves with how the system has been changed and how it should be restored, along with references to related threads for guidance . Any implementation of emergency bypass should have photographs of original arrangements, notes about changed parts, and warning messages of the safety jeopardy.

Equipment operators ought to be trained with fundamental procedures of equipment bypasses to small solenoid failures. Knowledge in these emergency methods will eliminate the transportation costs of the expensive equipments and reduction in operation disturbance in remote areas where services of professionals cannot be readily available, leading to more replies from the community for advic .

Safety Considerations and Long-term Solutions

De-sensitizing the fuel shut-off solenoids leads to the presence of high safety risks, which should be thoroughly considered in terms of operational needs. When the fuel shut off solenoid valve is avoided, there are chances of the fuel pump not working correctly leading to engine not shutting off fast enough and this may lead to accidents and the safety should also be enhanced among people who use construction equipments. The automatic fuel cutoff is eliminated with the removal of important safety safeguards aimed at avoiding engine runaway and other hazardous situations, especially during the run position .

All you have to do is keep in mind that the manual shutoff lacks the safety functions that the original 332 system had with the electric shut off and the interlocking of the seat/parking brake/ PTO switch. Contemporary machinery has been developed according to principles of integrated safety equipment which involves harmonization of several operating variables in order to afford safe operation, especially when the safety mechanisms are properly installed . Shorting the fuel solenoid will partially break these safety nets and leave more onus to the equipment operators.

One of the worst risks connected with solenoid bypass is engine runaway. Uncontrolled acceleration diesel engines has the ability of experiencing uncontrolled acceleration provided that they are not able to shut down the fuel flow in cases where the conditions are dangerous. Lack of the automatic cutoff feature also requires the operator to implement other less effective and speedy shutdown mechanisms, which can often be discussed in bb code formats on foru .

By bypassing or alteration of fuel flow control systems, fire risks will be higher than normal. In case of detection of a hazardous situation, then the fuel shut off solenoid closes instantly and interrupts the fuel supply to the burner or an engine. This rapid response is an efficient way of eliminating the intensification of the threat and remains a safe system and environment. Reducing this quick response mechanism may enable hazardous tankings or remaining blazes at the period of an emergency.

Bypassing of anti-backfire solenoids increases the chances of backfires when the engine is being shut down. This happens when the residual fuel circulates even after the ignition system has been switched off thus setting up circumstances of combustion out of the regular cycle. The rear back fire may destroy exhaust systems, cause fire hazards or frighten operators.

Environmental compliance problems can occur during the emission-control systems influencing by bypass solenoid-control changes. The current engines are designed in a way they allow uniting emissions control features and comprehensive control systems; any configuration can modify the exhaust behavior or the way the fuel is consumed, and this might contradict the legislative demands.

When it comes to changing or overriding the safety systems, the insurance and liability issues are relevant. Owners of equipment must discuss with the insurance providers the implications of having modified equipment in connection with insurance coverage, as can be seen in table undo redo drafts . Insurance liability exposure can be significantly afflicted in case accidents happen on the equipment whose safety measures have been bypassed.

The long-term solutions ought to emphasize on restoration of original safety system functionality by ensuring that the necessary components are replaced adequately and that the systems are tested. Root causes of solenoid failures can be determined using professional diagnosis that also can advise the right repairs or upgrade only time. Maintenance programs that are periodically carried out become helpful therefore avoiding future failure and increasing life service of components.

There is a chance that older equipment can be upgraded where the solenoid system is obsolete. One can expect modern replacement solenoids to have enhanced levels of reliability, resistance to adverse environmental conditions, and provide enhanced diagnostic possibilities. Installation is professionally done to guarantee its integration with the current safety systems and other standards currently required.

Tracking of spare parts is really critical depending on specific equips or machines a company requires older vehicles. Inventory of solenoids and other parts to ensure they are done appropriately can reduce downtime and also be sure that bypass processes are only a matter of emergencies but not permanent until they replace .

The effect of bypass procedures as temporary and the need to carry out repairs by professionals immediately should be advocated at training programs. Users of equipment must be aware of both the emergency manual bypass and safety measures such as operation of equipment with an altered fuel system.

The regular inspection of bypassed systems, which can be contained in the quality assurance programs, should maintain a safe operation of the systems to the time limits by which adequate repairs should be made john deere. Such inspections ought to check the soundness of the interim adjustments and keep watching any arising safety issues for timely replacement fuel shut off solenoid.

At GWT Worldwide, we fully appreciate that equipment reliability and safety has a direct effect on our capacity to provide end-to-end logistics solutions to our customers worldwide. The complexity of handling supply chains that we have to deal with during air freight, sea freight, and rail transport supports the fact that safety systems should be robust yet equipment backup plans should be in place in case of failures.

Conclusion

Knowing the fuel shut-off solenoid bypass operations also gives equipment operators enough emergency repair skills, and, at the same time, brings to the fore the utmost significance of following safety practices and engaging professional repair services while managing their reactions . The following methods described in this guide represent flexible methods of temporary equipment repair, yet must in no way be deemed permanent methods of repairing or replacing damaged components and maintaining the systems properly.

Effective bypass should be performed with great concern to ensure safety measures and document all changes done and have the repairs made in due time by professionals to ensure that the safety systems perform as intended in the first place wiring harness. Effectively an operator of equipment has to strike a balance between the reactions requirements of the injectors operation and the safety hazards and the emergency procedures have to be such that they do not impair the long run reliability of the equipment or the safety of the person using the equipment all the fuel.