Make sure to know the essential provisions to install a generator without a risk. Full description of distance requirements, ventilation, codes and safety precautions of residential and commercial During the proper location of generator, clearance requirements are very essential and ought to be fully practiced to ensure safety, compliance and the optimal performance. When you are considering generator placement while installing a home generator or standby generator in your house or commercial building., it is important to learn these requirements so that you can avoid accidents and dedicate that your warranty will be effective and also to be in line with the local codes and building codes. Generator clearance requirements incorporate several factors such as distance to buildings, ventilation requirements, gas lines and electrical safety.

As a professional service provider in the logistics industry that offers global freight forwarding/Supply chain solutions to its customers, we know how useful it will be to have proper equipment fitting like a home standby generator in the various markets all over the world. Shipping generators and associated equipment all over the world has taught us that it is important to ensure that the equipment is installed in accordance to the manufacturer specifications and local regulations to ensure the safety of the equipment.

Understanding Basic Generator Clearance Standards

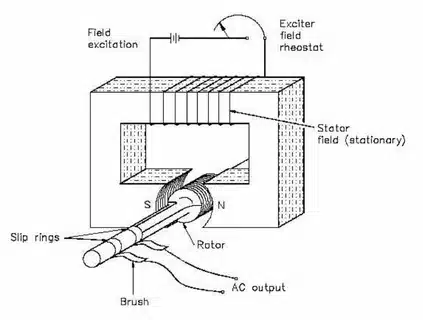

Basic Generator Clearance Standards The clearing of a generator whose design provides a minimum greater than required (code) clearance between insulators (or other parts) and normally energized parts is called clearance.

To avert fire hazards, designer poisoning by carbon monoxide petrol shortages, and equipment damage, manufacturers, local building codes, and national safety standards specify generator clearance requirements. Most jurisdictions follow the basic requirements issued by the National Fire Protection Association (NFPA) and International Building Code (IBC) which they customize according to the local circumstances.

The buffer around your generator is not only meant to supply ample ventilation during cooling but also to avoid the problem of heat damage to the surrounding walls and constructions, consider using a generator enclosure. , including combustible materials facilitate maintenance procedures, and ensure that the exhaust does not cause harm due to lack of adequacy. Not keeping proper clearances has led to overheating, premature breakage in equipment, code violations, and may result to a hazardous situation.

Distance Requirements from Buildings and Structures

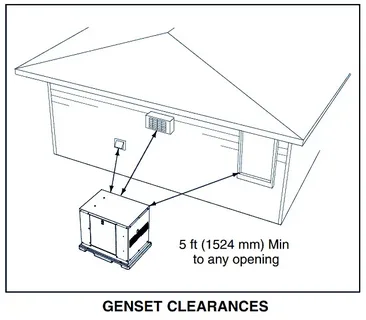

The most important thing with clearance planning is probably how far or close your generator is to different structures. Windows, doors and air intake vents need to be subjected to most clearance distances since they are capable of drawing exhaust gas to living areas. Most manufacturers recommend not less than 60 inches (5 feet) of clearance to these windows and openings, some jurisdictions may specify more.

The solid walls and other buildings should be left with 18-24 inches of free space so that there should be no heat accumulation and proper flow of air. The distance would also enable servicing procedures such as regular repairing which is a requirement in ensuring your generator is in its prime working condition. Installation of corners and trees can have some special elements where it can cause zones of air circulation.

Another key factor will be property lines, where most areas will demand the installation of generators at a distance of at least 5-10 feet away of the property lines. This is needed so that surrounding properties are not damaged by noise, exhaust systems, and a possible safety threat. The local setback requirements might be quite different between municipalities, so they are always worth checking before placing an installation.

Overhead clearances are also vital and most installations demand that the clearance of the generator is at least 36 inches in height, taking care to avoid any openings that can obstruct airflow. . This space does not allow the gathering of heat and proper exhaust dispersal. Site planning needs special consideration in places where power lines are low-hanging, and branches of trees, or building overhangs.

Ventilation and Air Circulation Considerations

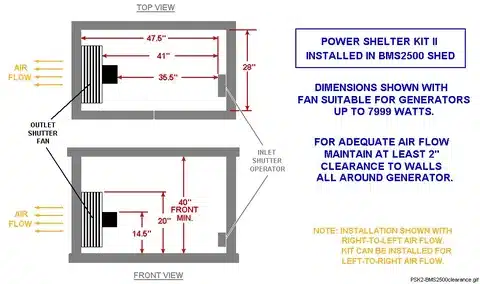

Generator operation requires proper ventilation which has an influence on performance as well as safety. Generators will demand a lot of airflow in the engine cooling and combustion process, thus the necessary ventilation space is exclusively out of question, which should also be verified through testing . The system that provides coolings should receive free access to the surrounding air, and the exhaust pipes must have free channels of dispersion.

The intakes of air should be clear of obstructions such as landscaping, storage or even snow that might inhibit airflows. Poor generation failure is also caused by the clogged air ducts that lead to poor cooling of the generator, which can create voids in airflow . Periodical inspection and maintenance of these are of importance to this reliability.

The clearance planning is influenced by natural air circulation patterns that surround your installation site. Such locations where airstagnation can easily occur like courtyards or surrounding tall buildings may need additional clearances to allow ventilation. Exhaust gas dispersal depends upon wind patterns as well which makes the placement very important to be safe and compliant with the structure .

Seasonal factors that could modify ventilation should be taken into account, snow cover, falling leaves or temporary materials like outdoor furniture cover. These variables should be considered in your planning of clearance to stay safe throughout the year.

Fuel Line Safety and Clearance Requirements

Installation of the fuel lines involves some clearance provisions to avoid leakages, damages and injury. Natural gas piping is to be sized and placed appropriately with non combustible materials to not interfere with the work of the generator and keep safe distance to the electricals. Installations involving Propane have other considerations regarding placement of tanks and neck-lines.

Fuel lines must be buried very deep underground and must be marked so that in the future, accidental damage does not occur due to some excavation work. Above ground segments have to be guarded against physical damages and adequate clearances against heating sources. The type of rigging used as flexible fuel connections is supposed to be tight enough to allow movement of generator when operating but not compressing fittings.

Emergency fuel shutoff valves should be accessible however located in a safe condition so that the exhaust and heat cannot physically reach it. Codes imposed by local authorities frequently indicate specific placement requirements of such safety gadgets, which must meet certain criteria . Fuel line clearances should be periodically checked because over time settlement or frost heaves or landscape changes may also alter safe clearances.

Determination of the fuel line clearances also takes into account maintenance access, that ensures that the connections can be serviced by technicians and that no hazards are exposed through this access. This consists of sufficient lighting in the workplace, firm working surfaces, and easily perceptible escape routes in case of emergencies.

Electrical Code Compliance and Safety Clearances

Electrical clearances that apply to generator installations need to be in accord with local amendments and the National Electrical Code (NEC). It shall have a main electrical disconnect that is placed in view of the generator, but a safe distance without direct exposure to the heat and exhaust. Extra consideration needs to be given to transfer switches, which normally should be given 36 inches of working space in front of the panel.

In the design of the tank, electrical conduit and wiring are to be separated sufficiently with regard to fuel lines and exhaust parts. Areas of high temperature adjacent to the generator use special wiring techniques and materials which are rated high temperature. The planning of electrical clearance is further complicated by ground fault protection and requirements of bonding.

Service panels and utility connections must have sufficient clearance around the areas so that the utility workers can operate freely. Clearance planning is influenced by many utilities having particular specifications on how generators can be interconnected. In the planning process, it is advisable to coordinate with your utility company early enough when you need to make significant changes to avoid huge bills later.

The disconnects (supplied to emergency needs) should be well marked and accessible by first responders. This usually determines the position of the generators with regard to the entrances of the property and building, which can link to emergency protocols .

Local Building Codes and Permit Requirements home standby generator

The national standards are often adjusted according to local codes, site conditions, climate and the preferences of a particular municipality. Salt air can predispose a need in coastal regions to zone greater clearances due to corrosion issues and regions that are exposed to extreme weather conditions may have specifications in the necessity of greater structural protections.

The permit procedures can widely differ in different jurisdictions, with one jurisdiction possibly needing detailed site plans with actual clearance measurements. Installing companies with local knowledge can make navigating them and comply with their requirements much easier. Most of the permit applications have been demanded to be accompanied by evidence of sufficient clearances.

Additional restrictions to the building codes may be placed by the homeowners association (HOA) rules, possibly referring to the placement of generator as well as requirements about the screening. Check out all relevant regulations prior to making up your certain installation plan to not conflict and stall.

It is possible to influence the existing installations due to regularly conducted updates in codes, which is why a periodic review of compliance should be undertaken. Grandfathering can save the installations already in place, however they must normally be altered or updated to fit current codes.

Maintenance Access and Long-term Safety Planning generator placement

The clearances should allow access to undertake long-term maintenance and to maintain the possibility of undertaking major maintenance work and the possibility of replacing equipment. All parts of the generator, e.g. air filters and oil dipsticks, as well as fuel connections and electric panels must have easy and safe access to service technicians.

It must take future changes into consideration, changes to the landscape, changes to the property and additions that could take place in the property and future that could affect the clearances. The apparently sufficient today may turn out to be a problem when your property starts changing with the time. The forethought of such future possibilities in the initial installations can save huge relocations in the future.

Clearance planning should be affected by seasonal requirements of maintenance, including snow removal or vegetation control. It may require larger additional clearings to accommodate the snow cover in areas that experience heavy falls and wider clear zones when a particular area is characterized with plant hardiness.

Repair services have to have emergency access, especially when power is disrupted and often such an access is needed during bad weather when other modes of access are likely to fail. Well-cleared and indicated passages to the generator improve safety and quicken responses to the service delivery.

Conclusion

There are specific generator clearance requirements that are central to safe, compliant and deemed reliable installation of a home generator . Some of these requirements included distance requirement to buildings and structures, sufficient ventilation area, safe fuel lines, electrical code requirements, local permit and long tear maintenance access to prevent fire hazard stationary wall . Being aware and complying with these requirements will help maintain your investment, guarantee safety of the family and keep you covered under the warranty.