Meta Description: How do diesel fuel shut-off solenoids work, what are common issues with them and how can they be easily solved. Engine and heavy equipment We cover the testing and repair of all engines and heavy equipments as well as the best brands.

What Is A Diesel Fuel Shut Off Solenoid?

Diesel fuel shut off solenoid is one of such major components which turn off or turn on the flow of the fuel to your engine. It is a small-sized device which is powered on to open and close a valve. Once started, fuel starts passing to the engine. Fuel goes off when you switch it off.

The most important components are:

- A fuel retaining valve body

- A magnetic force making coil

- An up and down-moving plunger

- Another spring that closes down the valve

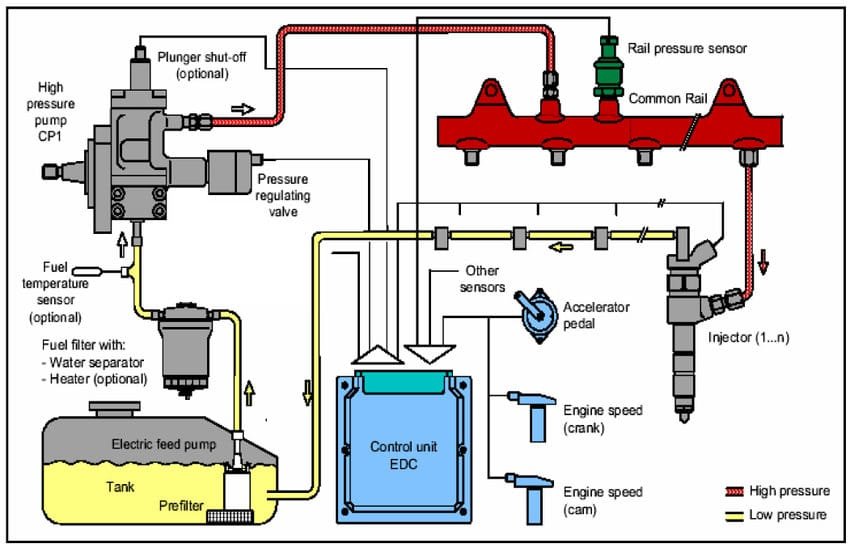

How The Diesel Fuel Solenoid Works

When you release power to the solenoid, you make a magnetic field. The plunger is pulled up by this field and in doing so the valve is opened. You can now have flow of fuel to your engine.

As you switch the power off, the spring makes the plunger move down. This seals the valve and prevents flow of fuel. Your engine will go off safely.

This system is useful in guarding your engine against:

- Standing fuel on board

- Unsafe conditions

- The ability to shut down remotely is required.

Common Problems With Fuel Shut Off Solenoids

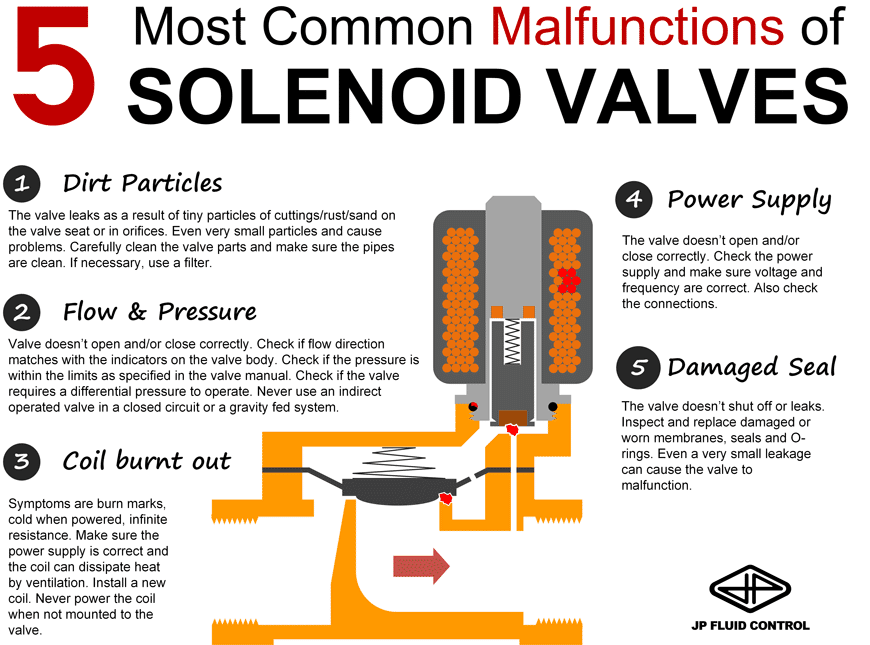

There is a variety of problems, which can cause the occurrence of your solenoid malfunction:

Power Issues

- Poor wires or loose plugs

- No authority that gets the unit Obtains E. L. A Quality.

- Incorrect voltages Wrong voltages

Dirt and Debris

- Valve Contamination by fuel crud

- The dirt of the moving parts

- Sticky parts brought by old fuel

Worn Parts

- Bad springs that don’t work

- Broken non-sealed sewer pipes that leak

- Degraded plunger/ coil

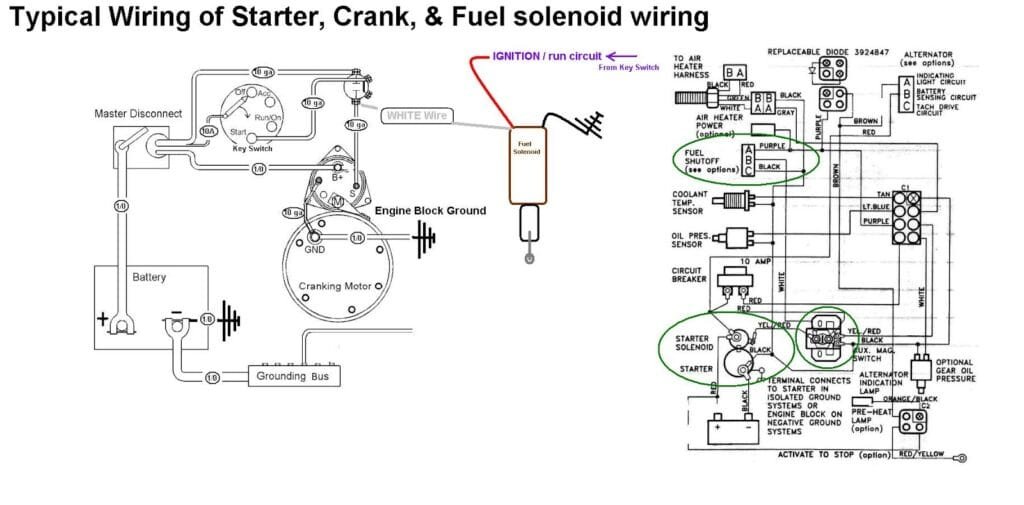

Control Problems

- Malpositioned operation commands

- Bad switches or relays

- Connectivity errors of computer systems

Step-By-Step Troubleshooting Guide

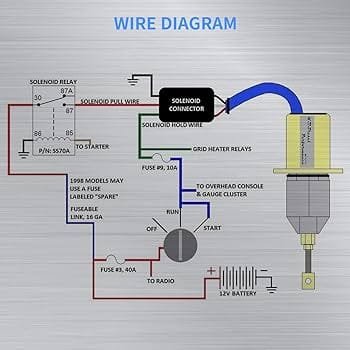

Check Power First

Check with a meter whether the power can access the solenoid. Look for:

- 12V or 24V by requirement

- Wire connections have to be cleaned and tightened.

- Good grounding

Test The Solenoid

The use of power should be heard with a click. No click =:

- Bad inside coil

- Stuck plunger

- No strength entering in

Clean The Unit

Lay the parts down and clean with:

- Clean diesel

- Debris brush

- New seals in case of necessity

Check Fuel Flow

Ensure that fuel is able to flow easily:

- Clean fuel pipes

- Clear obstructions Check to see that there are no obstructions.

- Pressure of fuel pump Test

Replace Bad Parts

The most replaceable parts:

- Worn springs

- Cracked seals

- Crisped coils

- Stuck plungers

Popular Diesel Fuel Solenoid Models

For Kubota Engines

- Part: SA-5176-12

- Voltage: 12V

- Fitting: D722, D902, Z482 engines

For Bobcat Equipment

- Part: 6667993

- Voltage: 12V

- Fits: Large variety of skid steers

For Deutz Engines

- Part: 04233841

- Voltage: 12V

- Applications: 912, 913, 914 engines

For John Deere Tractors

- Part: AM882277

- Voltage: 12V

- Applications: 670-1070 small tractors

When To Replace Your Solenoid

Change the diesel fuel shut off solenoid at:

- It won’t click when powered

- Leaking of fuel in the unit occurs

- Engine won’t shut off properly

- Coil checks display nothing in terms of continuity

- Multiple repairs haven’t worked

Conclusion

Knowing the working principle of the diesel fuel shut off solenoids would enable you to maintain the equipment better. These low but vital parts make engines work efficiently and without danger. There are some simple steps that can be followed in troubleshooting in case of problems, and in many cases, the problem can be resolved. In case of complex repair or replacement of a part consult a manual of your equipment or a certified technician. The exercise in maintaining such solenoids will guarantee smooth running of the engine hence avoiding the expensive time wasted during shutdown.