Meta Description: Cummins vs Perkins diesel generators engine comparison. Advice on the use of power, efficiency, cost, reliability through expert analysis so that businesses can make a decision of what to use as the generator engine depending on the requirement.

Failure by power to supply electricity can be disastrous to the activities of the business as it may cost firms thousands of dollars per hour through loss of productivity. Depending on the one you select, the Cummins or the Perkins diesel generator engine you choose will spell the difference between a business that operates smoothly or one that suffers costly downtimes. Both of them have championed their position as brands in the industries, though they deal with varied business needs and priorities.

Understanding Cummins Diesel Engines: Power and Performance Leaders

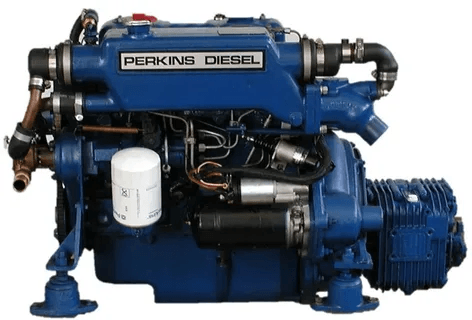

What Makes Cummins Stand Out in the Market

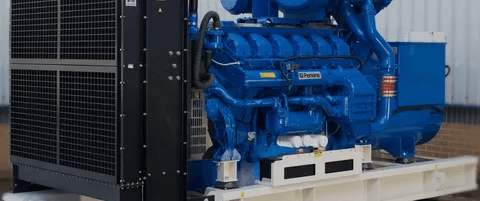

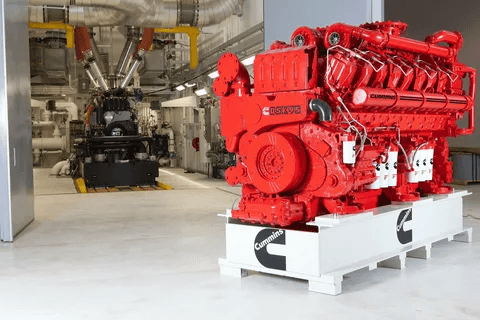

Cummins has established its reputation as the maker of high power output engines with incomparable durability. The engines that they manufacture are utilized to accomplish the toughest industrial uses, including the function of operating around the clock in data centers or providing emergency power to the hospital. Innovation has given the company highly sophisticated fuel injection systems, highly advanced and sophisticated electronic controls as well as strong construction that can still be used in situations when there are extreme operating conditions.

The international coverage of the brand provides great support as service centers and parts could be found on different continents. This wide network is equivalent to little downtime and speed in the resolution of maintenance problems, and this is why Cummins can be used in mission-critical applications.

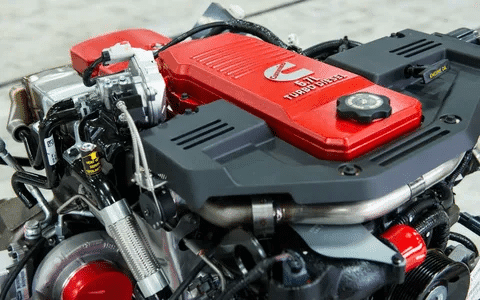

Key Technical Advantages of Cummins Engines

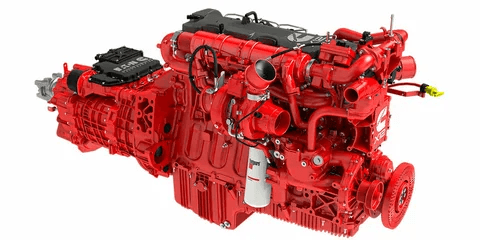

There are a number of technological innovations integrally salient in Cummins engines, which differentiates them with their competitors. They have hi-tech fuel systems that maximize the fuel-burn efficiency of the engines and at the same time maximize power output. The engines are sophisticated in electronic control modules that control operational parameters in real time ensuring optimal operation under variable loading conditions.

Cummins engines are built with an accent on durability and reliability. Through tough components, accuracy in manufacturing and intensive testing standard, these types of engines are capable of operating long periods with minimal residuals. The fact that they are reliable makes them a perfect choice used in applications that cannot afford failure of the generators.

Exploring Perkins Diesel Engines: Efficiency and Cost-Effectiveness

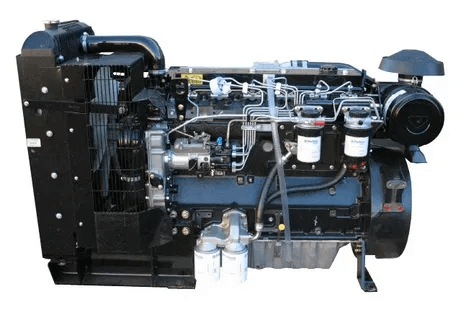

The Perkins Approach to Diesel Engine Design

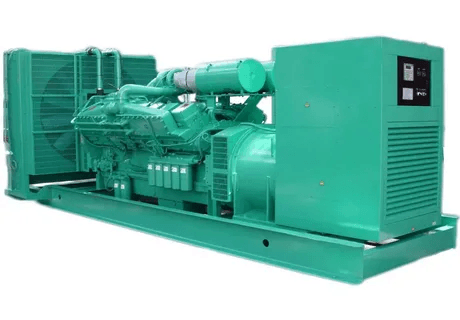

Perkins has taken its niche where it involves itself with fuel efficiency and cost efficient working. They have a long-term take on how their engines are built, such that the emphasis is more on long term savings in the operation of the engine than the absolute power of the engine. This strategy has seen Perkins engines be the favorite when it comes to providing businesses with power that they can rely on in terms of its efficiency and yet be able to reduce the cost of operations.

The engineering department of this company specialises in simple and easy-to-serve kinds of designs. The effect is to produce engines which are simpler to maintain, and do not need as specialized knowledge to service, and have more easily accessible spare parts. These all will considerably bring down the overall ownership cost of the engine through its life span.

Technical Features That Define Perkins Engines

Perkins engines also have a reputation of being highly fuel efficient which is as a result of a well thought through combustion chamber and their side of the story being good injection timing. Such engines normally save up to 10-15 percent of needed fuel in relation to other engines with similar power output used by other manufacturers hence leading to a lot of savings in the long run.

Their engines also have reduced noise, therefore, can be fitted in noise sensitive areas. The long service intervals cut down the maintenance period and the design is robust hence there is a steady performance during the life period of the engine.

Comprehensive Performance Comparison: Cummins vs Perkins

Power Output and Performance Characteristics

In comparing power outputs Cummins engines will tend to have higher power densities than the European equivalent engines and can therefore be used for applications with a high electrical generation demand. The engines are optimized in high demand cases in which the power needs change dramatically or, where peak power generation is essential.

Perkins engines have reasonably-powered output but concentrate on a regular performance range. They effectively offer consistent high power delivery which is just sufficient in most of the commercial and residential demands with the added advantage that they are highly efficient in fuel economy.

Fuel Efficiency and Operating Costs

Fuel efficiency is a major separating factor between these two brands. Perkins engines have a consistent record of better fuel economy that can at times consume 15-20 percent less fuel when compared to similar Cummins engines. Such efficiency directly transfers to lower operational costs, which are especially key to businesses that have a long generator running period.

Nevertheless, this extra fuel cost is paid back by Cummins engines in the form of their high power as well as their high-performance capabilities under harsh conditions. Whether to go economical and lean on fuel efficiency or raw power lies dependent on the particular need to be fulfilled by the application and usage pattern.

Durability and Maintenance Requirements

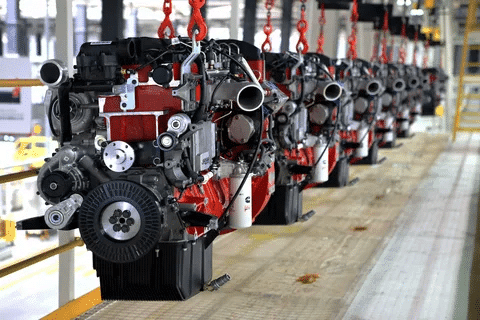

The two brands are so great in terms of durability though they vary in their use. Cummins engines are extreme duty engines, designed to operate in extreme conditions and under extreme duty with heavy duty parts with strong capabilities to withstand the harshness of the environment. They have more complex maintenance needs that usually need special expertise and original parts.

Perkins engines are very durable with a brilliant design and high-quality partnership. They do not require as complicated maintenance procedures and have more standard components, so in general, servicing is easier and cheaper.

Industry-Specific Applications and Recommendations

Industrial and Heavy-Duty Applications

Cummins engines can be the preferred solution to heavy industrial needs, data centers, hospitals, and manufacturing centers. Their capability to support constant operation, extreme load fluctuation, and tough environmental conditions also renders them into mission-critical applications especially where reliability matters the most.

Such types of engines are favorable in cases of high and permeable power with significant applications in powering large manufacturing equipment or supplying backup power to critical infrastructure. The reason given to justify the higher initial investment is that the engine can take up tough operational conditions.

Commercial and Residential Applications

Perkins engines are superior in their use into the commercial and residential areas in which they remain fuel efficient and cost effective. The reliability coupled with the economy of Perkins is appreciated on small to medium sized businesses, retail facilities and residential backup power plants.

The engines are especially appropriate to applications that have predictable power needs and frequent operating rhythms. They offer lower levels of noise with lower maintenance making them suitable in places of high populations or noise Santiago Hernandez – the National Rural Healthcare Association (NRHA) targets low ear itching levels or noise-sensitive regions.

Cost Analysis and Return on Investment

Initial Investment Considerations

The first cost only includes a part of the overall cost equation. The purchase prices of Cummins engines are usually high since they are constructed with high technology and are strong. Yet this extra cost is usually reflected in better performance and life expectancy under harsh conditions.

Perkins engines are competitive in terms of initial pricing and are high quality coupled with reliability. They are more appealing to businesses that have a tight budget or those applications where peak power output is not a big concern.

Long-Term Operating Costs

Long term running expenses include the cost of fuel, maintenance and availability of parts. Perkins engines usually have lower total cost of operation as they are cheaper in their fuel consumption and their maintenance is less complicated. Cost-saving is made possible by the availability of aftermarket parts and a reduced need to provide services.

Where Cummins engines, although they potentially experience higher operating costs, may be worth it in high performance applications that are highly demanding. Another aspect is that the wide network of support worldwide can help to reduce the costs of downtime which is essential in critical application.

Making the Right Choice for Your Business

Assessing Your Power Requirements

The initial decision when it comes to deciding Cummins vs. Perkins refers to a proper evaluation of your power needs. Plan with your present purposes, future expansion possibilities and future alterations in power requirement. Power applications that have heavy loads fluctuations are often better suited to a Cummins engine but stable moderate requirements are better suited to a Perkins engine.

The role of the environment in the choice of an engine is also very important. Rough operations environment, high and low temperatures, and overloading demands are normally factors that work in favor of the sturdy build and the sophisticated controls of Cummins engines.

Budget and Operational Priorities

You should not limit yourself to the initial purchasing price but you should also consider the long-term cost of operation. When fuel economy and reduced maintenance prices are orthopederal, Perkins engines are more frequently economical. In applications where the utmost availability and performance is of primary importance, the extra expenditure on the Cummins engines can be warranted.

Take into consideration the presence of qualified technicians and service in your location. The large network coverage by Cummins offers an advantage when it comes to far nature spots, and the ease of general maintenance by Perkins, which could be managed with local technical people.

Expert Guidance and Professional Support

The Importance of Professional Consultation

To choose the appropriate generator engine, you have to make professional analysis of your individual needs, operating conditions and long term goals. Professional consultation will make the best of everything, including technical specifications as well as economics of operations.

At GWT Worldwide we have expanded our logistics skills into matters touching on the intricacies of industrial equipment selection and placement. We are a professional logistics service company that deals in international freight forwarding and supply chain services, and we know how important efficient power infrastructure is in the operation of a business in any part of the world.

Comprehensive Service and Support

These two, Cummins and Perkins, both have far-reaching service support sources, however, service quality and service access can differ depending on the location. Take into account the number of authorized service centers in your area, supply chains to get access to the qualified technicians and parts.

The company GWT Worldwide has a good experience in international logistics and supply chain management which gives us important information about the practical matters of the generator engine choice especially when you have a business with an international environment or when the logistic details are complicated.

Conclusion

The decision on whether to use Cummins or Perkins diesel generator engines will be determined by the nature of your business, the conditions under which you operate as well as your long term goals. The Cummins engines are known to be best suited in high powered demanding uses where both the reliability and performance is key, whereas perkins engines have better fuel economy and are more economical on moderate power uses. The two brands are equally reliable, have good worldwide support and would be an appropriate brand to use in various business situations.