Find out what occurs when diesel is pumped in a gasoline-fuelled engine, the fatalities that it can cause, what you can do as soon as you detect it, and some tips on how this can be avoided. Hear this expensive mistake by specialized persons.

The most dangerous fuel misplacing that happens is putting gasoline in a diesel engine which can cost thousands of dollars in repairs. Conversely, this error will be disastrous to your diesel engine and fuel system in contrast to the vice versa. Learning the process that occurs when the fuel gets contaminated is especially important to vehicle owners, fleet managers, and individuals operating diesel powered machines.

Understanding the Fundamental Differences Between Diesel and Gasoline

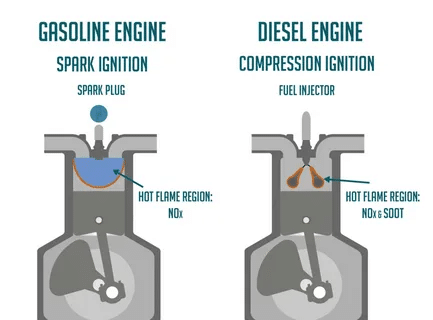

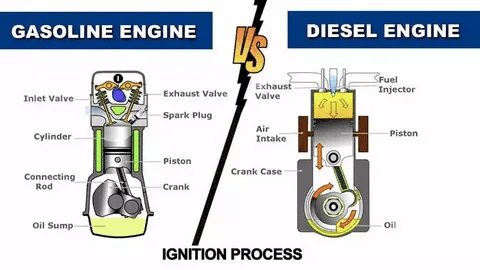

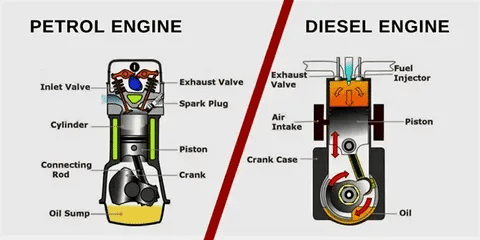

Diesel engines and gasoline run on totally different principles in their designated engines. Diesel powered engines operate on the principle of compression ignition, here ignition of the fuel is caused by high pressure and temperature generated by compression. The fuel is also used as a lubricant of the important parts of the engine, such as in the fuel injection system.

Gasoline, however, is spark ignited and its chemical characteristics are totally different. When gasoline gets into a diesel system it is not a lubricant but it is a solvent and once gasoline engages a diesel system then it starts wearing at the fine balance required by diesel engines to operate properly.

Immediate Chemical Reactions When Gas Enters a Diesel Engine

When the gasoline combines with diesel fuel, certain instantaneous chemical reactions are initiated. Compared to diesel, gasoline is much less viscous and, therefore, thinner, which deprives it of lubricating properties on which the operation of the system of diesel injection relies. This causes a direct crisis of lubrication inside the fuel system.

The gasoline exerts itself as a solvent and dissolves rubber seals and gaskets and other materials that are expected to operate with the smoke chemical composition of diesel. This solvent activity becomes active after several minutes after contamination, so time is of the essence when it comes to preventing the occurrence of massive damage.

Critical Damage to the Fuel Injection System

Damages to the fuel contaminated with gasoline fall on the fuel injection system. Diesel engines Modern diesel engines incorporate very tight-tolerance high-pressure fuel injection systems. All these parts are based on the lubricating factor of diesel fuel to avoid metal on metal contact during the operation.

Once gasoline gets into this system it removes the lubrication and destroys the injection pumps, fuel rails and injectors instantly. A high pressure fuel pump, that can cost several thousands of dollars to replace, is especially susceptible to this kind of damage.

In case of unclean fuel, fuel injectors themselves get clogged and damaged permanently in just a few minutes. Such precise parts are dependent on the characteristic features of diesel in order to sustain their sprays and periodicity. Injectors may become stuck, leak, or die because of gasoline contamination.

Engine Performance Issues and Symptoms

There are some different symptoms of engines with gasoline contaminated diesel fuel. Rough idling, strange noises of the engine, a reduced power output are the first signs you can learn about. The motor might have difficulty in keeping the RPMs at the same value and may keep stalling.

The more the contamination takes place, the more serious the symptoms develop. The engine will either not start, emit too much smoke out the exhaust or work very roughly when it does. Such symptoms show that already there is internal damage in progress.

The computerized diesel engines that are current have complex systems that can provoke even several warning lights and error codes. Fuel contamination may lead to abnormal fuel pressure, other abnormalities on injections timing and such others that the systems can sense.

Long-term Consequences and Extensive Damage

Failure to fix the problem when a diesel engine is being used with gasoline contaminated fuel will result in increased destruction of the machine at a high cost. The contamination of the fuel system may become spread over the whole engine, not only the injection system, but also fuel lines, filters, and fuel tank itself.

There might be damage on the internal engine parts because of poor lubrication, as well as changed combustion properties. Excessive wear in pistons, rings and the cylinder walls may result in poor compression and ultimate engine failure.

The gasoline tank and other relevant parts might be necessary to be changed in case the rubber content of the gasoline is dissolved or the gasoline is subsumed in the tank in which case, cleaning is not possible. This may increase the cost of repair by thousands of dollars.

Immediate Steps to Take After Fuel Contamination

Once you notice the gasoline has been inserted in a diesel engine, it is imperative to act instantly. Never try to Turn on the engine which is already off. When the engine is in operation, turn it off to avoid the unnecessary damage.

Wait until a skilful diesel mechanic or a mobile fuel arrives. There are professional fuel system cleaning and contamination clearing services which have specialized equipment of attending to such kind of emergency.

Record the case in detail, namely, the gram organization of the gasoline introduced, level of fuel in the tank, and any symptoms noticed. This will be useful in terms of insurance calculation and repair estimation.

Professional Repair and Restoration Process

There are quite a number of important steps in the process of professional remediation of gasoline contamination. All the fuel parts should be emptied such as the tank, the fuel lines, and the injection system. It involves special machinery and skills so that all the polluted derivation fuel is removed.

The fuelsystem has the requirement to inspect all its parts in case they have been damaged. There will be a necessity to change fuel filters, and some components of the injection system will either have to be rebuilt or replaced, depending on the degree of contamination and possible work with contaminating fuel.

When gasoline has harmed some internal components or contamination is severe, fuel tank may also require professional cleaning or replacement. The procedure may take a few days and is connected with high labor rising prices.

Prevention Strategies and Best Practices

They need to be keen and encapsulate awareness to prevent fuel contamination when filling up with fuel. Always ensure you check the kind of fuel you are going to fill. Most of the fleet operators possess fuel cards or systems that prohibit the occurrence of cross-contamination by controlling accessibility to the right fuel types.

Accidental contamination can be avoided by the implementation of clear labeling systems concerning fuel storage and dispensing equipment. Drivers and equipment operator training programs must also focus on the issue of fuel type verification.

It is also advisable that fuel system additives be used so as to identify contamination early enough. There are also products that may aid in finding out that there is a fuel mix up before excessive damage is made, but again, this may not be used as the main way through which prevention is made.

Cost Analysis and Financial Impact

The economic costs of filling in the diesel engine may be high. Small pollution that is detected early could be hundreds of dollars to clean and clear the fuel system and the filters. Nevertheless, when the engine is working on contaminated fuel, the expenses very soon rise to thousands of dollars.

It may cost up to 5,000-15,000 dollars or even more to repair significantly (fuel injection system replacement and so on) depending on the model of the vehicle and the amount of damage. In worst cases, the cost of engine replacement or rebuilding can reach $20,000 and more depending on the engine or specially thru a heavy-duty diesel engine.

The coverage of insurance cover regarding fuel contamination is considerably different. Certain policies can compensate the accidental pollution, whereas others can not. It is important in financial preparations to know about your cover before it happens.

Special Considerations for Different Vehicle Types

Various kinds of the diesel vehicle and equipment are exposed to different levels of risk to gasoline contamination. The fact that modern passenger car diesel engines use more complicated injection systems placed under a high pressure, it is even more prone to damage as its tolerances are narrow.

Commercial vehicles and heavy-duty trucks might have a stronger fuel system but the possibility of damage is still high. Repair home treatments on commercial cars may be even more expensive because they require special parts and may have longer refreshes.

Agricultural and building machines are different in this sense since the contamination incidents frequently happen in a place that is remote, and professional assistance may not be obtained right away. It is important to have emergency response plans to such scenarios.

Conclusion

The effects of fueling a diesel engine with gasoline goes much deeper than an ordinary fuel mix up. The fuel injection systems may be destroyed as well as damage caused to internal engine parts and even lead the engine into total liquidation unless these are taken care of soon. The most effective way to ensure that careless fueling practice, inadequate training as well as ignorance is avoided to prevent this expensive error is through prevention. In the worse case, when contamination actually happens, timely professional help is needed to limit the damage and get the vehicle back on the road with no harm to the personnel.