Meta Description: Learn about the meaning of Tier 4 generator, what it supersedes, and what is the difference between the Tier 3 and the need of capable, environmentally friendly generators that require only 10% of the emissions compared to the traditional ones by the EPA.

Understanding EPA Tier Classifications for Generators

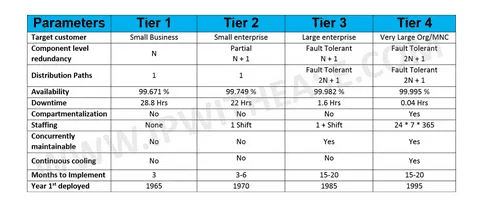

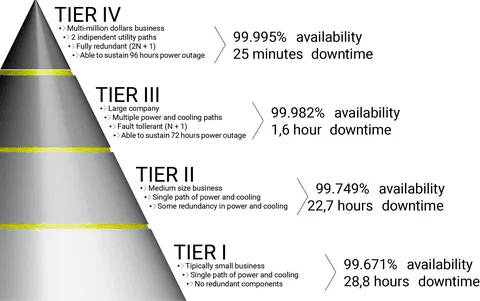

To manage the nonroad diesel engines emission environmental protection agency (EPA) has put in place comprehensive tier system that governs nonroad diesel engines, generators included. These are placed into ranges such as Tier 1-4 where every increasing level of these tiers has increasingly strict standards regarding their emissions. A tier system was the developed plan by a systematic reduction of harmful pollutants like nitrogen oxides (NOx), BPM (particulate matter) and substances that contain sulfur that are powered by diesel operated equipment.

EPA has established several tiers of emission rates on nonroad compression-ignition engines employed in generators and the tier has been implemented in a sequentially difficult manner starting with the 1st till the 4th tier as the most advanced set of technology towards minimizing emission.

What is a Tier 4 Generator?

A tier 4 generator is the highest level in the diesel-powered generation technology of emissions. The Tier-4 emission standards intended to be gradual and thereby started to be implemented as the final rule signed on May 11, 2004 entered into force in 2008-2015 and mandated to cut the emissions of PM and NOx by approximately 90%. These generators also feature the most advanced emissions controls systems in effect that translate into virtually zero pollution ratings in relation to previous tier classification.

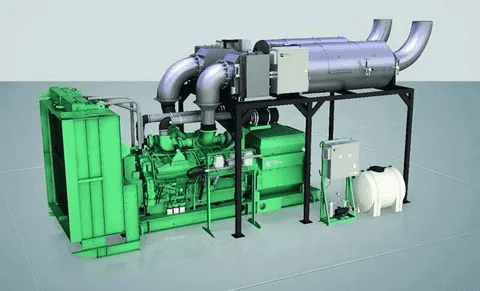

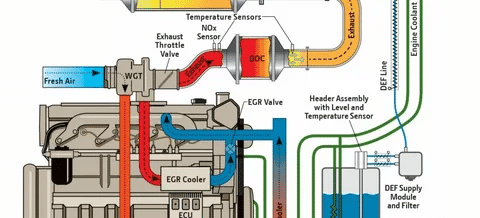

The Tier 4 generators are developed with the use that requires continuous operation and can be utilized in the environmentally-sensitive application. To handle these strict demands they use innovative technologies such as the use of diesel particulate filters (DPF), selective catalytic reduction (SCR) and exhaust gas recirculation (EGR) systems..

Key Features of Tier 4 Generators

Advanced Emissions Control Technology

These standards are met by Tier 4 generators which employ the use of advanced emission control technologies such as exhaust gas recirculation, and diesel particulate filters. The advanced aftertreatment systems are designed in a way that they result in a drastic drop in harmful emissions yet they preserve optimum performance of the engine.

Ultra-Low Sulfur Diesel Fuel Requirement

Tier 4 titled the switching process to be run between 2008 and 2015 with 90 percent reduction in PM and NOx as new standard and new ultra-low sulfur diesel fuel is necessary to set up these standards. It is through this fuel requirement that the pollutant reduction mechanisms or methods of controlling emissions become efficient so as to have the maximum reduction of the pollutants.

Near-Zero Emission Performance

Current Tier IV compliant diesel motors have already reduced both NOx and PM by 99 percent and overall tailpipe emissions by 95 percent. This incredible feat is the result of decades of technology in the development of diesel engines and emission control.

Tier 4 vs Tier 3 Generators: Key Differences

Emissions Performance Gap

The Tier 4 generators produce 90 percent low particulate matter, nitrogen oxides and sulfur compared to Tier 3 generators and with stiffer emission controls, a relatively low level of NOx and PM emissions are produced in Tier 4. This significant decrease makes Tier 4 generators much more environmentally friendly than before.

Regulatory Compliance Requirements

The standards in the Tier 4 generators surpass a long way in the production of clean burn with the result that a particulate reduction of 90 percent has been achieved following the already advanced performance of Tier 3. Although Tier 3 generators can be used when Tier 3 generators are required in emergency use, Tier 4 is required in most jurisdictions when using generators in prime power.

Technology Complexity

Tier 4 generators also feature more advanced pollution control systems with several aftertreatment units that are to be calibrated most precisely and maintained. Tier 3 generators are a bit less sophisticated and use simpler technology of emissions control which is easier to maintain and less effective in pollutants reduction.

Applications and Use Cases

Prime Power Applications

It is only the prime generators that require Tier 4 standards whereas standby (or emergency) gensets only comply with Tiers 2 and 3, but not Tier 4. Continuous or long- term Prime power generators should conform to Tier 4 so as to create less environmental destruction.

Industrial and Commercial Use

The tier 4 generators are crucial to the industries that require constant generation of power, such as manufacturing constructs, data centers, and construction sites that operate within environmentally sensitive regions. They are also high emissions performers hence applicable in the cities where the air quality is highly controlled.

Environmental Compliance

Tier 4 generators increase the presence of businesses in the regions that have strict environmental regulations since these generators are able to produce exhaust emissions that match the strictest requirements. It complies with these rules to prevent regulatory fines and corporate environmental responsibility.

Benefits of Choosing Tier 4 Generators

Environmental Impact Reduction

It is anticipated that new Tier 4 engines will lower two major pollutants, namely, particulate matter (PM) and nitrogen oxides(NOx), of which NOx results in ground-level ozone formation whereas exposures through particulate matter are known to have an unfavorable health impact on the respiratory system. This minimization has a direct advantage on the health of people and the environment.

Regulatory Future-Proofing

With Tier 4 generators, you will be keeping abreast of emissions regulations now and in the future. Tier 4 generators have regulatory security as the environment keeps on becoming stricter all over the world.

Enhanced Corporate Social Responsibility

Companies that employ Tier 4 generators show their desire to have an environmentally friendly approach which in turn can support their brand image and fulfill their sustainability objectives. Customers, investors and regulatory authorities are getting more and more attached to this commitment.

Considerations for Tier 4 Generator Selection

Initial Investment and Operating Costs

Generators at 4th level normally have a larger investment cost as it has enhanced emission controlling technology. The incremental cost is however almost always justified by the long term benefits of regulatory compliance and environmental performance.

Maintenance Requirements

Tier 4 generators have advanced emissions control technology that needs special maintenance measures and expert technicians. Different systems of DPF, SCR catalysts, and others should be regularly checked to work at their best.

Fuel Quality Requirements

Tier 4 generating sets need the newly fuel with low sulfur diesel to meet the expected level of reduction in emissions. On some applications this fuel need can influence the selection of fuel sources and storage.

About GWT Worldwide

Shenzhen Guanwutong International Freighter Forwarding Co., Ltd. (GWT Worldwide) is a logistic service provider which is expert in the area of international supply chain management and international freight forwarding. Our global solutions comprise air freight, sea freight, China-Europe railway, international express, customs clearance, warehousing, Amazon FBA shipping service. Through its superior technology in the transport industry and international connections with partners of trust, GWT Worldwide will deliver efficient, transparent and reliable logistics services to businesses across the globe and we will always be your preferred partner in global trade.

Conclusion

Tier 4 generators are the highest quality and eco-friendly diesel generator technology that exists in the current world. These generators are capable of delivering reliable power under critical applications yet satisfying the strict environmental standards of EPA since they reduce toxic emissions by an impressive 90% than in the previous levels. Large upfront costs and specialized maintenance are the undesirable characteristics of the advanced emissions control systems, but the outstanding environmental returns are received by businesses and communities because of the negative impacts which the uncontrollable emissions have on the environment.