What is Generator Wet Stacking?

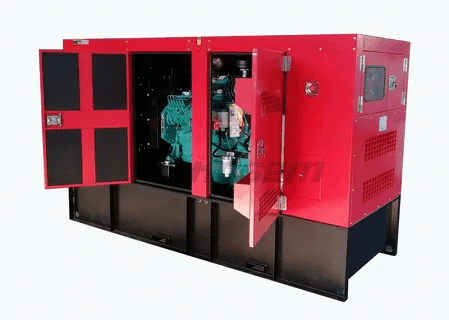

Generator wet stacking is a severe situation where the diesel generators are put under a low load at high times. The phenomena leave an unburnt fuel that gets collected in the exhaust system of the generator forming a wet carbon-rich deposit that may severely destroy your generator and undermine its performance.

Diesel generators operating at less than optimum load (in most cases less than 30 percent of their rated capacity) do not attain adequate temperatures to fully combust the fuel in the combustion chamber. This partially combusted mixture results in raw diesel fuel mixing with the carbon build up causing the defining “wet stack” look in the exhaust system.

Understanding the Science Behind Wet Stacking

The problem of wet stacking is an issue that can be traced back to the fundamentals of how diesel engine works. To work as efficiently as possible, diesel generators are optimized to work on a higher load range, usually somewhere between 70-80 % of their rated capacity. When its levels are low, then a number of undesirable conditions will arise:

The temperature of the combustion chamber keeps being insufficient to ensure that the fuel is fully consumed and unburnt hydrocarbons are released into the tailpipe. All these fuels condense and mix with carbon particles forming a sticky, tar like substance which coats all along the exhaust system.

Also, the operating temperatures are low thus the engine cannot achieve optimal thermal efficiency level. This waste is aggravated by further production of incomplete combustion cycles due to this inefficiency, further adding to the total size of fuels that ended up in the exhaust system without being burnt.

Common Causes of Generator Wet Stacking

Knowledge of the main reasons behind wet stacking allows the operators to recognize the condition before it sets in so hence prevent it before becoming worse. The most frequent ones are:

Chronic Light Loading: Constant underloading of generators to below operating under 30 percent of the rated capacity generates conditions that are optimal to wet stacking. That frequently happens in Systems that take advantage of an oversized generator on a small facility, or a low load time of the day.

Constant No-Load Testing: Another most common reason is frequent testing without sufficient load on it. No-load testing on weekly or monthly maintenance schedules is common in many facilities and is valuable in assuring the generator to start correctly, but since no appreciable engine wear occurs during this type of test can itself lead to wet stacking unless offset by periodic stuffed usage.

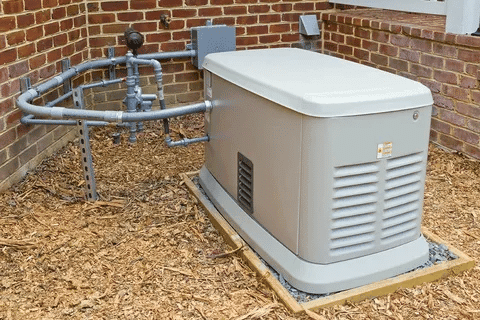

Selecting the wrong size of generator: Most definitely, the wrong issue generating the wet stacking problem is installing the wrong size of generator relative to the application of the generator. The large generators will hardly have time to work within their preferred loading range and this will create a constant state of light loading.

Long Idling: Long idling makes generators, usually to operate heat in cold weather, highly susceptible to wet stacking. In a situation of a low load and long-term operation, the environment is still good to store more fuel in it.

Early Warning Signs and Symptoms

Prevention of devastating generator failure with thousands of dollars saved on repairs can be achieved by identification of early warning signs of wet stacking. Important clues are:

Obvious Exhaust Indicators: The most noticeable wet stack symptom is usually black, sooty smoke pouring out of exhaust pipes when an engine is starting or running. The exhaust can also have a strong smell of fuel and oily deposits at the surface close to the outlet of the exhaust.

Performance Degradation: Wet stack in generators can result in decreased power performance, high-rough idling and generally a poor load hold ability. Another well-known symptom is engine misfiring and irregular work patterns.

Fuel System Problems: Wet stacking may be signaled by greater fuel use with no power output rise in return. Moreover, the fuel filters can get polluted at some earlier speed as compared to usual maintenance procedures.

Physical Evidence: Oily wet deposits ought to be seen all around the exhaust system, especially at joints and connections to be sure there is concrete evidence of wet stacking. Such deposits usually smell strongly of diesel fuel and they could dribble off the exhaust components.

Prevention Strategies for Wet Stacking

Wet stacking cannot be prevented solely by necessary measures at the operational level, but it is necessary to control the processes of maintenance as well. The best measures of prevention are:

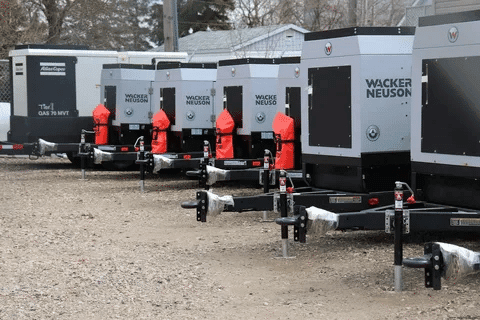

Load Bank Testing: The best preventive approach towards eliminating wet stacking is by conducting regular load bank testing. Load banks are sources of artificial electric loads which enable the generators to perform within their optimal capacities ranges. Early-stage wet stacking can be prevented, and in some cases reversed by conducting monthly load bank testing at 75-100 percent capacity load between 1-2 hours.

Right Generator Selection: It is important to have the correct generators according to what they must do. Good practice is to ensure that the normal operating loads are within the capacity of 70-80 percent. This will guarantee the use of optimum combustion temperatures and eliminates the low-load conditions that lead to wet stacking.

Operational Best Practices: As much as possible, we want to avoid running the plant at a light load over long periods. When light loading must be indulged, intersperse it with higher operating periods to ash out the deposits thus allowing smaller loads. Defining optimal loading levels is possible by combining several smaller loads or temporarily loading less critical awaiting the kind of loads.

Maintenance Scheduling: Create maintenance schedules which comprise of regular loaded operations and not just no-load testings. This method will guarantee that the generators will work adequately and in practical conditions.

Professional Solutions and Remediation

In case wet stacking already took place, there are a couple of professional solutions that will bring generator performance back and help avoid additional damage:

Carbon Cleaning Service: Expert carbon cleaning services do away with massed-up materials on the exhaust system, the combustion chambers, and the fuel injectors. This is in most cases done with special cleaning chemicals along with specialized equipment that can clean the carbon buildup without ruining engine parts.

Fuel System Cleaning: This includes extensive fuel system clean-up cycle, which is aimed at cleaning up contamination in the entire fuel delivery system. This involves cleaning of fuel tanks, change of filters and fuel line treatment to eliminate set deposits and contamination.

Engine Overhaul: In acute instances, the engine could require comprehensive overhaul in getting it back to good functionality. This mostly entails the restructuring or changing significant parts of the engine that have been destroyed through long periods of wet stacking.

Replacement of exhaust systems: In worst cases, complete replacements of exhaust systems can be necessitated. Present day exhaust systems oftentimes come with specifications to reduce the effects of wet stacking and enhance the general durability of the system.

Cost Analysis and Financial Impact

Financial cost of the wet stacking is far reaching than the immediate repair cost. These costs can provide the argument that correct prevention programs should be established:

Direct Repair Costs: The cost of dealing with wet stacking may range between several thousands dollars due to minor cleaning treatments to tens of thousands dollars due to serious engine rebuilds. The repair of the exhaust system alone may cost 5,000-15,000 dollars depending on the size and complexity of a generator.

Operation Losses: Operation losses may be caused by downtime of generators due to repair of the generator leading to huge losses, especially in critical cases. The costs further rises because of emergency back up powers that need to supply energy when repairs are being undertaken.

Shortened equipment life: The process of wet stacking reduces the equipment life by far and may necessitate early replacement of an expensive equipment. This is an extremely high hidden cost of poor prevention of wet stacking.

Rising Insurance: Generators that are known to have issues with wet stacking might have raised insurance premiums or be limited in their insurance coverage which costs over time.

Industry Best Practices and Standards

Some of the best practices in the industry could be used to ensure performance and long life of generators:

NFPA Standards: The National Fire Protection Association gives the guidelines of testing and maintaining the generators that contain the suggestions aimed at preventing wet stacking. NFPA 110 is specifically concerned with requirements of testing emergency generators.

Manufacturer recommendations: These guidelines on load testing and the maintenance schedules are given by generator manufacturers. After these recommendations, warranties have to be kept and the performance is to be in the best form.

Professional Training: Proper training to maintenance personnel on the wet stacking prevention and recognition is one of the ways to maintain the reliability of the generators. A lot of manufacturers and industry groups provide specific training courses.

Record Keeping and Documentation: It is good to keep detailed records of the generator operation, testing and maintain in order to establish trends that can point to trends in wet stacking problems that have and can develop. Its documentation is also useful in cases of warranty and in the field of insurance.

Choosing the Right Service Provider

It is important to choose qualified services providers to take care of generator maintenance and wet stacking corrections:

Technical Skills: Seek service providers that have a certain history of working with diesel generators and wet stacking clean-ups. A representation of the provider being certified by large generator manufacturers signifies special knowledge and training.

Equipment and Facilities: The effective rehabilitation of wet stacking demands special equipment and facilities. The service provider must be able to access load banks, cleaning equipment and diagnostic tools so as to provide complete service.

Response Capabilities: The critical applications need emergency service capabilities. Emergency response ought to be 24-hours and service providers must have sufficient manpower to counter emergencies.

Logistics Support: Businesses may also need transportation of generators or temporary power solutions when they are in process of repairing their equipment, the companies in the service industry that can offer extensive logistics support would provide substantial benefits.

Conclusion

Generator wet stacking is a problematic issue to the reliability and life of the diesel generator, and yet, it can be avoided completely with a little knowledge and forward planning. The mitigation to the occurrence of successful wet stacking is to observe the right loading levels, carry out test load regimes and adherence to recommended maintenance by the manufacturer. Symptoms that lead to wet stacking can be noticed early enough hence interrupted to avoid expensive repairing and replacing of equipment.