Meta Description: Get the most important requirements necessary to conduct generator testing according to NFPA 110 such as weekly, monthly, and annual testing procedures of emergency power systems. Make sure that extensive testing procedures are used.

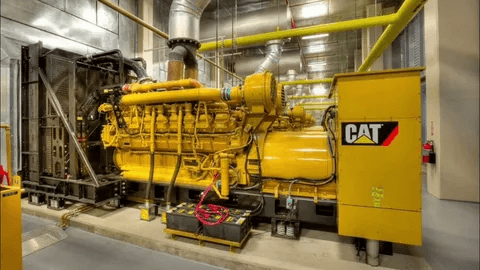

Emergency power systems are the lifelines in the event of the power outage; they safeguard lives, as well as sustain the vital operations. The National Fire Protection Association (NFPA) 110 standard that offers detailed instructions on emergency and standby power systems also leads to properly organized examination procedures that will guarantee the successful operation of emergency power systems during actual need. Such requirements are crucial knowledge of facility managers, building owners and anyone involved in the maintenance of emergency power systems.

Understanding NFPA 110 Emergency Power System Standards

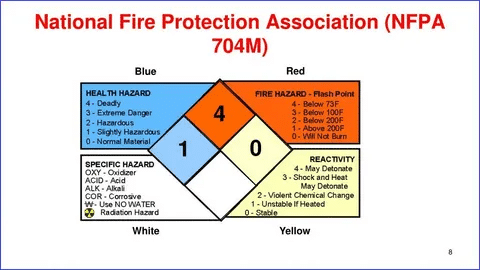

NFPA 110 specifies the means of emergency power systems that support backup power in event of utility outages. Level 1 generator is a generator failure which may cause death or serious injury. A level 2 generator is one, the failure of which would not lead to injury potentially resulting in loss of life. The standard covers power source, transfer equipment, controls, supervisory equipment and accessory equipment that may be required to provide electrical power to selected circuits during an emergency event.

The classification system is used to establish certain testing requirements depending upon the criticality of the app. Level 1 systems are normally used within hospitals, life safety systems, and critical infrastructures where loss of life may occur in case of failure. Level 2 systems are the ones that provide general applications not essential enough to create situations that are life threatening but had the applications gone wrong then there would have been inconveniences.

Weekly Inspection Requirements Under NFPA 110

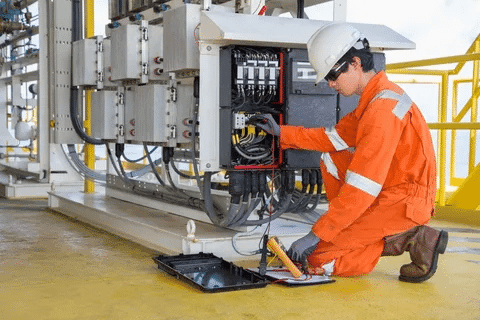

NFPA 110 mandates that the EPSS, along with all appurtenant components (i.e. generator sets, transfer switches, circuit breakers, fuel systems and other equipment) must be inspected weekly with an under-load exercise at least once in a month. A strong base of acceptable emergency power system care involves weekly inspection of the system so that any potential problems are discovered at a point of time prior to critical failure.

Weekly inspections should include the following: the technicians should make sure of the presence of fuel, look out for visible leaks, confirm the condition and level of electrolyte in batteries and ascertain the indications from control panels. Testing of all alarms and warning system should be carried out to ascertain functionality. The parameters on the engine, like oil pressure, coolant temperature, and battery voltage have to be recorded within reasonable limits.

The provision of the inspection process contains checking of operation of transfer switches, automatic start abilities and the verification of all safety systems. Such tests allow avoiding sudden failures and keeping the system ready to be activated in emergencies.

Monthly Load Testing Requirements

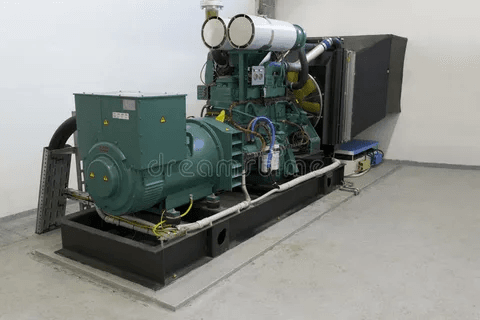

To be confirmed ready, generators have to be tested monthly on their load. This test comprises: Operating the generator under load of actual or equivalent making sure it operates 30 minutes and at least 30 % nameplate rating. The most essential part of NFPA 110 compliance is monthly testing, which highlights the fact that generator is capable of operating when service is required.

The exercising under load must last at least 30 minutes monthly. Diesel generators should run at least 30 percent of the nameplate rating of kW, or at recommended exhaust temperatures. This is necessary to eliminate wet stacking, the situation where fuel that has not burned collects in the exhaust system, which may lead to the damage of the engine and poor performance.

The verification test conducted every month should identify the full regulation of voltage and frequency, the transfer to the automatic switch, record the parameters that are indicated by the system. All the tests should be documented as the date, duration, load level, and any abnormality witnessed during the test.

Annual and Load Bank Testing Requirements

Lack of fulfilling these requirements will make the EPSS be subjected to the annual load bank testing. Whereby generators may fail to meet the demand of 30 percent in monthly testing required and this leads to the compulsory extra load bank tests. Nonetheless, roughly as a rule of thumb, the NFPA 110 standard proposes that at least once per year, loaded bank test must be conducted.

Load bank testing is associated with the application of an external load on the generator to make the generator work at full-load capacity and over a longer duration. The reason to test everything to this extent is the fact that it confirms that the generator will respond under maximum demand and will highlight problems that may be missed at other lighter load loads.

And once every 36 months, you will have to operate Level 1 EPSS systems until the time indicated in the Class in your application within four hours. This longer duration of testing is so that Level 1 system should be able to support critically longer-term outages.

Documentation and Record Keeping

Documentation is part and parcel of compliance to NFPA 110. Any test done should be well recorded with respect to test dates, test periods, load levels attained, system parameters that have been measured and also deficiencies encountered. This can be used to yield historical trends as to the performance of the system; and during inspections, evidence of compliance.

Operators should sign off on test logs and provide information about witnesses when necessary, as well as appropriate corrective measures on any difficulties found. Reviewing of these records on a regular basis will assist in recognising patterns that may be signs of emerging issues that were needing to be looked into.

Fuel System Testing and Maintenance

NFPA 110 defines certain specifications of the fuel systems of the emergency generators. You must follow the NFPA 110 fuel storage and testing requirements closely and in order to ensure that you do not default you must work properly in size your fuel tanks and carrying out prior fuel maintenance. Testing of the quality of fuel guarantees that the generator would be available to start and run in case of need.

Fuel systems must regularly be tested on how contaminated the system is, amount of water in the system as well as degradation of the fuel. Diesel fuel is specially of concern because of the inclination to form deposits and reproduce microbial life with time. Fuel polishing and addition treatment usually ensures quality of fuel and eliminates issues with generator starting.

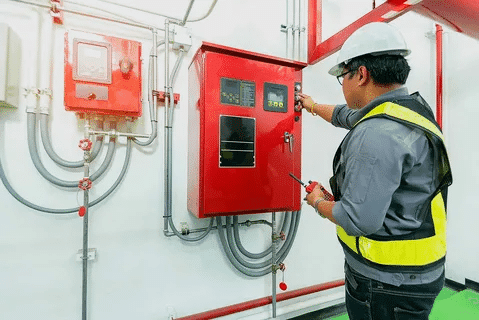

Transfer Switch Testing Requirements

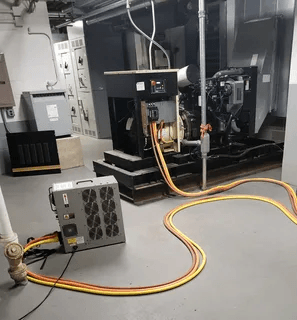

Transfer switches are an essential part of emergency power systems, and switch loads between the utility source and the generator during power losses. NFPA 110 mandates periodical loading on transfer switches, validation of timing of transfer switches, load transfer capabilities and returning to utility power functions.

Testing should confirm that the utility power loss is sensed and timer delays are operated correctly prior to starting of the generator and that load transfer is carried out without reversal to the critical circuits. Return transfer testing also tests that the system correctly responds to utility power restoration and also can transfer loads back at will.

Compliance Enforcement and Authority Having Jurisdiction

NFPA 110 compliances are enforced by the Authority Having Jurisdiction (AHJ). This may involve local fire agencies, building departments, or other codes administrative organizations who enforce the codes. The local enforcement practice assists in the right compliance measures.

Particular requirements of the NFPA 110 may be controversially interpreted in different jurisdictions and it is important to coordinate with local authorities to know what is required of any particular jurisdiction. Frequent contact with the AHJ allows avoiding compliance disputes and makes sure testing programs are fit to regulations in the area.

Common Compliance Challenges and Solutions

In order to be compliant with the NFPA 110 many facilities face problems connected to insufficient load testing equipment, lack of documentation, or knowledge about the exact requirements. Some of these issues can be dealt with through the implementation of automated testing systems in a manner that will guarantee uniform adherence.

Engaging experienced service providers who are familiar with the requirements of NFPA 110 is one of the ways to ensure appropriate testing processes and reports. Frequent training of facility personnel that is part of the generator maintenance also help to yield better compliance and reliability of the system.

Conclusion

NFPA 110 generator test requirements provide in-depth procedures to maintain the reliability of the emergency power systems when the safety and life of people and other viable businesses are threatened by backup power. This multi-level strategy of weekly inspections, monthly load testing, and annual comprehensive testing offers various chances to recognize and resolve any possible problem prior to it leads to the collapses in the system. The appropriate compliance means that you should familiarize yourself with the particular requirements of the kind of system you have, qualify the same through a consistent approach of conducting tests, and keep an elaborate back up on all the operations.