What Size Generator to Run 1.5 HP Air Compressor: Complete Power Requirements Guide

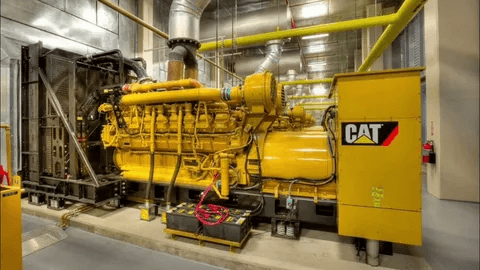

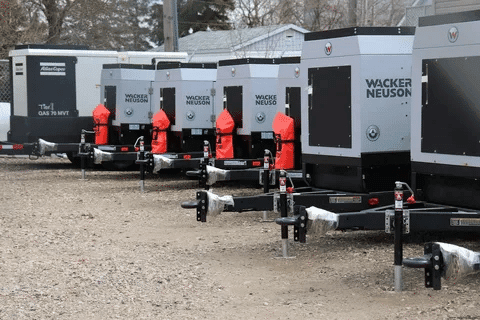

To run an air compressor of 1.5 HP, one needs about 6,000 starting watts and 2,200 running watts, meaning a 7,000-8,000 watt generator is the best selection that can work reliably. The details are mainly the consideration of starting surge demands, healthy safety measures, and the selection of good quality equipment which has a reasonable margin of power to ensure efficient performance at all times. Be it portable generators or standby generators, you are sure that your sizing is adequate to enable your air compressor to run well yet guard the two units against damage occasioned by the insufficient power supply.