Introduction

India’s lithium-ion battery manufacturing business continues to expand quickly as the nation develops independent energy supply with eco-friendly power solutions. The government targets electric vehicles and renewable energy use so battery production at home has become essential for national strategy, contributing to a sustainable future . This study reviews the present state of lithium-ion battery manufacturing in India including lithium ion battery solutions, information about established businesses and new companies plus their technology breakthroughs and market prospects.

The Rise of India’s Lithium-ion Battery Industry

Lithium-ion batteries made a strong market growth in India during the past ten years, showing signs of exponential growth . Environmental factors including lower production costs and enhanced technologies together with government incentives under the PLI scheme made domestic battery manufacturers more capable. As India moves forward with its independence plans both in energy and basic technology production, it develops its domestic electric vehicle battery and lithium-ion battery sector.

Different industries need lithium-ion batteries for diverse applications including cars, consumer devices, manufacturing tools and electricity storage. India has chosen the battery industry to anchor its strategy for industrial development as a global manufacturing leader.

Key Players in Indian Lithium-ion Battery Manufacturing

Established Manufacturers

Exide Industries

Exide Industries remains one of India’s oldest and leading battery manufacturing companies. After building its lead-acid battery business the company diversified into lithium-ion batteries by partnering with external organizations and investing in their operations to leverage cutting edge technology . Exide teamed up with Leclanché of Switzerland to start Nexcharge which builds lithium-ion batteries at its Gujarat production center. The plant creates lithium ion battery packs and modules that power diverse products like electric vehicles and power systems to store energy.

Amara Raja Batteries

Amara Raja Batteries has developed important lithium-ion technology programs. The company continues to develop advanced lithium ion batteries technology through research and development on how to make batteries work best in India. Amara Raja runs its plants with state-of-the-art equipment that produces lithium-ion batteries with exceptional performance and safer quality.

Tata Chemicals

The Tata Chemicals organization from Tata Group placed heavy investments into lithium-ion battery production facilities. The company’s production strategy starts with battery assembly and continues into making essential components like battery substances and control systems at its manufacturing facility . By making every step of battery manufacturing within one facility Tata Chemicals maintains quality standards and lowers its imports of raw materials.

Emerging Battery Manufacturers

Lohum Cleantech

Lohum Cleantech stands apart in India as a lithium-ion battery manufacturer and recycler making up the newest generation of industry colleagues. The business undertakes both battery creation and disposal procedures to make its operations more environmentally sustainable, particularly in energy storage systems . Lohum creates batteries suitable for electric low-speed cars and energy storage solutions platforms plus devices used by consumers.

Log9 Materials

Log9 Materials stands out as a startup company through its advanced battery technology that delivers fast charging. Samsung SDI creates batteries customized for electric vehicles used under tough ambient conditions. Log9 creates high performance lithium-ion batteries from unique cell chemistry that lets users charge faster for automotive applications more cycles with better safety.

Grinntech

Grinntech in Chennai designs and produces lithium-ion batteries made especially for electric vehicles in India. The business offers battery packages for motorbikes, two-wheelers to three-wheelers and automobiles that run on passenger cars, catering to various applications . Grinntech lets car manufacturers match their vehicle’s battery components to different mobility uses through its flexible design system.

Government Initiatives Boosting Local Manufacturing

The Indian government uses different policies to drive lithium-ion battery manufacturing within national borders.

Production-Linked Incentive (PLI) Scheme

India designers the Advanced Chemistry Cell battery PLI scheme as the critical part of its plan to develop battery competitiveness. With an 18,100 crore Indian Rupee budget the scheme gives financial rewards to battery makers who reach energy density levels plus hit production targets. The scheme tries to create energy storage systems and 50 GWh of battery production facilities that help India be less dependent on battery imports, highlighting the key features of local production .

Faster Adoption and Manufacturing of Electric Vehicles (FAME) Policy

The FAME policy creates more battery demand that helps manufacturers succeed. When FAME offers subsidies for electric vehicle buying it creates stable battery demand which helps manufacturers understand better when to expand their production capabilities, ultimately aiming for increased range . The second part of FAME encourages battery makers to expand production within the territory of India.

National Mission on Transformative Mobility and Battery Storage

Different parts of government collaborate on all aspects of battery production research and recycling into a unified mission. The mission takes a complete view of battery processing that starts at material acquisition while adding value until its final disposal. Through its effort, the mission promotes unified criteria for lithium-ion batteries, including lithium iron phosphate, regardless of their application.

Technological Innovations in Indian Battery Manufacturing

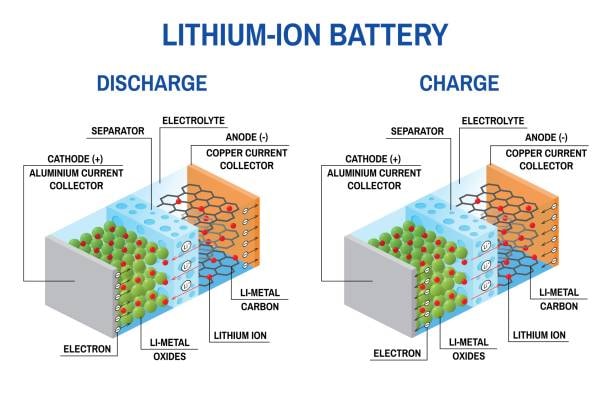

Indigenous Cell Chemistry Development

Indian battery makers fund scientific studies to produce battery cells that work well under local environmental factors. These organizations solve problems by creating battery solutions for hot weather areas with dust and different user patterns. Through local research efforts manufacturers seek new extraction methods to replace imported cobalt and nickel materials.

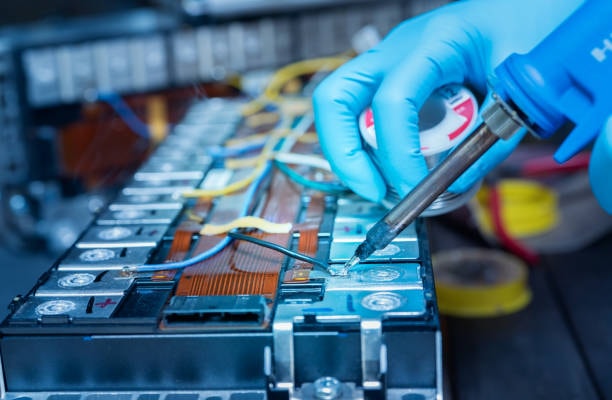

Advanced Battery Management Systems

Indian companies develop advanced battery management systems to boost performance safety and prolong battery life. The systems use machine learning to forecast battery actions and manage charging to avoid failures through automatic detection. BMS systems made in India include special features that match the electrical grid and weather patterns found throughout the country.

Manufacturing Process Innovations

Indian manufacturers apply advanced production methods to make their operations more effective and cut expenses. Manufacturers use three new methods to make electrode parts and automate the assembly steps. These advancements make production more energy-efficient and enable higher output without quality problems.

Challenges Facing Indian Battery Manufacturers

Raw Material Accessibility

India imports most of its required supplies of battery materials because its own resources contain minimal lithium cobalt and nickel. When manufacturers rely heavily on imported materials for production they expose their supply networks to problems in stability and pricing, especially within the automobile industry . The government has started finding foreign suppliers and looks into urban mining techniques yet concerns about raw material access stay difficult to overcome.

Technology Gaps

The companies making batteries in India have not yet matched the expertise of worldwide industry leaders. The industry needs more training for making batteries and improving its production scale for mass production while advancing its production technology to ensure quality and customer satisfaction. Strong links between research and development must remain active to create effective collaboration between organizations.

Quality and Safety Standards

Industry growth depends strongly on meeting international quality and safety requirements as India works to boost battery manufacturing. As India produces more batteries, companies need to make sure every product meets reliable standards of quality and safety, contributing to environmental sustainability . The battery industry team works with official authorities to make quality standards that follow international benchmarks while meeting Indian baselines.

Future Outlook and Opportunities

Market Growth Projections

The Indian lithium-ion battery market will expand by more than 30% every year through the next five years. The battery industry will grow fast because more people start using electric vehicles and renewable energy systems and there is stronger demand for consumer tech. The need for lithium-ion batteries in India will increase to 150 GWh annually by 2030, which opens business possibilities for battery producers and lithium ion battery suppliers in the country.

Potential for Export Markets

Indian battery manufacturers begin to sell products to foreign customers after becoming stronger at battery production. Indian battery manufacturers find robust business opportunities in Southeast Asian, African, and Middle Eastern markets because they serve applications that require cost-efficient solutions. Our success in exports will mainly come from gaining international quality standards and developing advantages against low-cost competitors.

Recycling and Circular Economy

Battery recycling helps both Indian companies save money on foreign materials and helps resolve environmental troubles. Many Indian companies use new recycling processes to take valuable materials from used batteries. The growing number of used lithium-ion batteries requires the industry to start recycling as part of its reliable energy storage solutions essential business process.

Regional Manufacturing Hubs

Gujarat Battery Manufacturing Cluster

Lithium-ion battery manufacturing businesses have chosen Gujarat as their main production area. The key reasons to establish battery production in Gujarat include its strong industrial base alongside port access and dependable power sources as well as good state support. loyd battery producers have more opportunities to work with common suppliers and teach each other what they know.

Tamil Nadu Electric Vehicle Ecosystem

The strong automotive sector in Tamil Nadu now produces lithium-ion batteries as well. The state has a proven history in precision manufacturing combined with experienced engineers which benefits battery manufacturers. Companies based in Tamil Nadu can work more effectively with nearby electric vehicle makers thanks to their close locations.

Maharashtra’s Technology-Focused Approach

Maharashtra hosts several technology-intensive battery manufacturing operations, particularly around Pune and Mumbai. The operations depend heavily on scientific research methods to develop products that need premium specialized functions. The state’s universities and colleges supply many qualified workers to the technology manufacturers in this area.

Battery Applications and Market Segments

Electric Mobility Solutions

The electric vehicle industry demands the largest amount of lithium-ion batteries throughout India. This segment encompasses:

- To power electric two-wheelers scooter and motorcycle companies need small lightweight batteries that hold moderate power content.

- Both auto-rickshaw drivers and delivery vehicle operators demand batteries able to handle many charging cycles at an affordable price ola electric.

- Car and SUV drivers need energy-dense batteries with temperature-balancing features.

- Buses and trucks need batteries specially made for their extreme use and fast charge requirements.

Indian companies produce battery products designed for various mobilitySegment two and three-wheelers take top position among these markets.

Renewable Energy Integration

Lithium-ion batteries become more in demand each year as companies develop them to integrate renewable power systems. These applications include:

- Solar-plus-storage systems for residential and commercial buildings

- Stable renewable power grids depend on energy storage facilities at the power station level

- Microgrids for rural electrification and telecom tower backup tata motors

Persistent power fluctuations from solar and wind energy create strong storage needs that enable battery producers to find important business opportunities.

Consumer Electronics and Portable Devices

People continue to require lithium-ion batteries for their devices. Indian battery companies targeting this market segment offer international quality products at low prices. Manufacturing lithium-ion batteries for consumer electronic gives producers a steady business volume at low production costs.

Sustainability Initiatives in Battery Manufacturing

Renewable Energy Powered Production

Battery producers in India use increasing amounts of renewable energy to run their manufacturing plants. The strategy saves energy resources during battery creation and benefits environmental management plans. Several companies are now operating their production plants through rooftop solar panels and clean energy agreements ups systems.

Water Conservation and Waste Reduction

The battery production process uses much water and produces many waste products. Indian manufacturers use high-tech programs that recover waste water and eliminate water discharge altogether to protect the environment. Companies adopt different methods to reduce waste like collecting solvents for reuse and recycling used electrode components along with returning package materials to use again suzuki motor corporation.

Life Cycle Assessment and Carbon Footprint Reduction

Companies that are progressive about their production assess everything from raw materials to product end-of-life to see where their activities produce the biggest damage to the environment. The evaluations help us locate specific areas to fix in order to make less damage to the environment. Organizations working to decrease their carbon emissions do this by making production changes solar energy systems, fixing energy waste problems, and lowering emissions across their supply system.

International Partnerships and Technology Transfer

Joint Ventures with Global Leaders

Various Indian battery firms now team up with major global battery producers through joint business ventures. Our agreements with leading technology companies make it possible for us to gain technology benefits faster and enter new markets more easily. Several Indian industries work together with South Korean, Japanese , European and Korean battery experts to develop their battery capabilities lithium ion cells.

Research Collaborations with Global Institutions

Indian battery firms develop their technology through partnerships with academic and research organizations from around the world. These partnerships work on several research topics including solid-state batteries tech breakthroughs and better ways to make battery electrodes lithium battery technology. The exchanged knowledge keeps Indian battery producers ahead of market changes in battery technology.

Technology Licensing Arrangements

Indian battery producers are working with major companies around the world through technology transfer agreements. The arrangements enable companies to use tested technologies in their domestic production process ev battery. Companies turn to technology licensing as they work to create local production capabilities.

Conclusion

The lithium-ion battery production sector in India starts a path to substantial expansion during the following ten years. The meeting of government backing with entrepreneurial ways and strong market growth makes this industry improve. Despite raw materials problems, including lithium reserves, and technical and quality standards issues solar power systems, Indian battery makers show excellent creativity and strategy to solve these problems.

How India develops its battery making industry will determine its path toward a clean energy future and drive its business success. More batteries made in the country will lower prices to help people buy and store renewable energy in electric vehicles. The growing industry benefits will push adoption faster and develop the complete manufacturing business system.

The battery production industry shows that India can build itself into a major lithium-ion battery producer at the global level. Indian battery manufacturers can outperform competitors worldwide when they upgrade their manufacturing through research and eco-friendly methods.