Introduction

The serial connection of lithium batteries became a core idea in electrical engineering which directs modern advances in power storage technology. The serial arrangement of batteries produces higher voltage outputs through combined voltage without changing current capacity which supports diverse uses. Serial battery connection serves as a basic operational principle that supports various power systems ranging from electronic devices to extensive energy reserve solutions.

Industrial operations depend on serial battery connections because of their ability to adapt to different projects at various scales. Multiple applications depend on serial battery connections which adapt voltages between everyday electronic devices and renewable energy grid battery banks. Any person who operates in electrical design or maintenance must grasp serial battery systems, including their amp hours and benefits alongside performance constraints.

Modern global power needs require efficient battery systems, especially for charging batteries, to become more important with each passing day. The integration of renewable energy technology and transportation electrification and reliable backup power solutions depend on optimized battery configuration systems. Serial connections provide precise voltage requirement matching among these systems together with effective energy storage management methods.

The study investigates serial battery connection principles alongside their practical uses and proper installation methods together with present limitations and predicted future developments. The guide provides students at all skills levels and professionals and common users with an in-depth knowledge of fundamental electrical configurations, particularly when using two or more batteries .

Fundamentals of Serial Battery Connections

Basic Principles of Serial Connection

The electrical system created by serial connections links each battery with the negative terminal of the preceding unit to its positive terminal. A serial battery connection provides an electrical conduction path which travels step by step from one unit to the next, contributing to the total capacity of the system . When placed in a serial connection multiple batteries accumulate their individual voltages but still have the same capacity rating as a single battery from the series.

When you place three 1.5V AA batteries in sequence the resulting voltage becomes 4.5V. Serial connections provide an optimal solution for electrical systems needing elevated voltage and sufficient amp hour capacity because the batteries’ voltages add up successively. A serial circuit yields its total voltage through this mathematical rule:

V<sub>total</sub> = V<sub>1</sub> + V<sub>2</sub> + V<sub>3</sub> + … + V<sub>n</sub>

The calculation to determine total voltage in serial connections uses V<sub>total</sub> for the complete circuit and V<sub>1</sub>, V<sub>2</sub> and other values for each battery voltage.

The electrical current inside a series configuration keeps the same value in every section of the circuit. The quantity of electric current stays constant throughout each battery within the chain structure regardless of their distinct characteristics. System architecture that relates to battery management benefits from this property specifically when dealing with various capacity batteries and different internal resistances, including those from batteries in parallel .

Contrast with Parallel Connections

The complete comprehension of serial connections requires direct comparison with the process of series parallel connection in battery systems. A parallel battery circuit connects all positive terminals together at one point and both negative terminals exist as a separate connection at a different point. The same electrical voltage output of one battery remains while the capability to deliver current grows with this arrangement.

The main distinction between serial and parallel connectivity involves two different aspects.

- The serial connection system raises the voltage output while preserving electrical current capacity levels.

- The arrangement of batteries in parallel maintains the output voltage and at the same time enhances their load-bearing capability.

The voltage remains at 1.5V while the capacity increases four times when four 1.5V AA batteries are connected in parallel since each battery maintains 1.5V output. The basic operational differences between serial and parallel wiring determine which configuration gets selected for various uses.

Multiple practical systems combine series and parallel connections (series-parallel) that enable them to gain increased voltage output while simultaneously boosting their capacity by connecting more batteries .

Electrical Properties of Series Connections

Multiple electrical characteristics affect the functioning of serial-battery connections since each battery links to the next.

- Internal Resistance: A series connection of batteries leads to accumulated internal resistances that produce increased heat from power losses. The resistance from each component builds up gradually because of how especially vital it is in applications that meet or exceed high current levels.

- Current Flow: The same current flows through all batteries in a series connection. This fundamental characteristic enables correct examination of battery power consumption throughout different usage periods. The first battery to run out in a serial chain will be the one with the lowest capacity since it drains before the others which can result in system breakdown.

- Charging Behavior: A series charging system requires attentive balancing to protect cells from overcharge because the charging current must traverse all batteries one by one. One major obstacle for serial battery management appears during this process.

- Voltage Distribution: An optimal series battery connection will deliver equal voltage among every contained battery cell. The manufacturing variations and charge state differences between cells lead to unbalanced voltage distribution so sophisticated systems need balancing components.

- Failure Modes: When one battery fails open-circuit in a serial connection the string will completely lose its ability to connect. This “weakest link” characteristic necessitates careful monitoring and redundancy in critical applications battery individually.

The fundamental properties of battery systems need thorough understanding to design secure battery systems while considering potential risks such as short circuits across different applications.

Applications of Serial Battery Connections

Consumer Electronics

Customer electronics use serial arrays of batteries as their standard configuration. The operating voltage of remote controls and flashlights and portable audio devices can be achieved by connecting AA, AAA and other standard batteries in a serial arrangement increased amp hour capacity.

Digital cameras combine four AA batteries in a serial link to deliver roughly 6V power for their operations. The operating voltage requirements of laptop battery packs are achieved through several lithium-ion cells connected in series either at 11.1V by using three cells or at 14.8V by using four cells.

Other common examples include:

- Wireless keyboards alongside mice utilize two connected AAA batteries to generate 3V power supply.

- Bluetooth speakers exercise multiple lithium-ion cells connected in serial for their operation.

- Digital cameras (usually 4-6V from series-connected batteries)

- Children’s toys normally combine series-connected batteries from the AA or AAA family to operate.

- The smartwatches and fitness trackers embedded with small lithium cells function as wearable technology through series connections.

Modern electronic devices need serial battery connections because their small size requires sufficient voltage delivery from compact designs wire batteries. Design engineers choose small battery assemblies in series over one large cell, as opposed to batteries in parallel, because they need to meet voltage demands alongside restricted spatial requirements all the batteries voltage stays.

Automotive and Transportation

The automotive industry depends completely on serial-linked battery cells for operation. The standard lead-acid auto battery within a 12V system organizes six identical 2V cells through serial interconnection inside its structure. Modern electric vehicles (EVs) are equipped with battery packs that use hundreds to thousands of individual lithium-ion cells connected through parallel and serial fashion, achieving optimal battery bank voltage .

A Tesla Model S battery pack reaches approximately 400V through its serial connection of multiple modules which contain multiple cells each. The high voltage system provides both high power efficiency to electric motors and low-current loss reduction how many batteries.

Other transportation applications include:

- Electric bicycles (typically 36V or 48V from series-connected cells)

- Electric scooters and motorcycles (48V to 72V battery systems)

- Golf carts (commonly 36V or 48V from six or eight 6V batteries in series)

- The power system design for boats uses connected 12V batteries in series configuration to deliver 24V voltage.

- Electric forklifts and industrial equipment (often 48V or higher)

Manufacturers continue to innovate serial battery setups through voltage optimization to enhance the efficiency and safety as well as performance of electric transportation systems thinner wiring.

Renewable Energy Storage Systems

Home renewable energy storage systems together with utility-scale applications heavily depend on serial connections for proper operation. The battery bank of home solar systems consists of serial-connected 12V batteries which produce either 24V or 48V output voltage. The elevated voltage requirement lowers power generation current needs which results in enhanced energy transfer efficiency while permitting cable reductions.

Utility-scale battery storage systems need serial connections to achieve needed voltages that enable proper grid connection. Such systems function at hundreds or thousands of volts since this enables efficient energy storage as well as distribution capabilities.

Specific applications include:

- Residential off-grid solar systems (typically 24V or 48V battery banks)

- A solar system built for grid-tied operations includes batteries and operates at 48V or higher voltage.

- Community microgrids operate using voltages at various levels whose specifications depend on the installation size.

- Utility-scale energy storage (high-voltage serial connections)

- Telecommunications backup power (typically 48V systems)

System designers achieve maximum efficiency through their power conversion equipment by using serial connections which permit matching battery voltage to specific requirements.

Industrial and Commercial Applications

Serial battery connections in industrial operations provide power to backup installations and material handling equipment in addition to diverse other applications. UPS systems use multiple batteries linked in series to generate power levels required by the protected equipment.

Industrially-used electric equipment such as forklifts operates from 24V, 36V or 48V battery setups that connect different battery cells in series. The power and operational efficiency of these work-intensive machines increase as a result of increased voltage levels.

Additional industrial applications include:

- Data center backup power (large serial-connected battery strings)

- Systematic emergency lights rely on battery arrays functioning at 24V.

- Industrial control systems and PLCs (programmable logic controllers) backup

- Oil and gas industry monitoring equipment in remote locations

- Railway signaling and switching systems

Emergency exit lighting combined with security systems and point-of-sale backup power receive their power from serial battery arrays that commercial facilities implement. Serial connections deliver stable overall performance together with adjustable scalability which makes them suitable for vital applications that need absolute performance reliability.

Design Considerations for Serial Battery Systems

Voltage Requirements and Planning

As a starting point for designing serial batteries you need to know how much voltage the equipment demands. This involves:

- Before designing the battery system you must discover how much power each powered device requires.

- Choosing Operating Limits Means Setting the Most and Least Acceptable Voltages for Use

- You should pick matching batteries with their matching volts for your system needs

A system may need 24V power so it can operate using two 12V batteries arranged in series or four 6V batteries joined together in series. The final selection happens based on other features like room size, total weight and the types of batteries we can use.

Voltage planning needs special consideration for three main points.

- Voltage Drop Under Load: Setting battery voltage above minimum usage level will help prevent output voltage drop during current delivery.

- End-of-Discharge Voltage: We establish the lowest functioning voltage level that enables our equipment to run correctly.

- Temperature Effects: Batteries release less power at colder temperatures so their voltage output declines.

- Aging Effects: Old age affects how batteries work so you must start them with more voltage to counteract this change

Modern power systems include voltage regulation elements that keep output stable when battery voltage fluctuates because of these operating conditions.

Battery Matching and Selection

Connecting multiple batteries works properly only when you use matched units. Every battery in a serial link system should match these requirements.

- Of the same chemistry (lead-acid, lithium-ion, etc.)

- From the same manufacturer

- Of the same model and capacity rating

- The batteries should enter the connection with equal remaining charge at the same moment.

- Of similar age and usage history

When more than one battery does not match properly during charging and discharging they can shorten the lifespan of both individual cells and the entire battery system.

For batteries connected in series choose items based on these main standards:

- Capacity Rating: Determining runtime for the entire system

- Maximum Discharge Rate: All batteries should meet and handle the maximum current output needed for the system

- Cycle Life: Look for batteries with proper durability levels for your system needs.

- Self-Discharge Rate: Systems that stay unused need batteries with minimal power drain when not in use

- Operating Temperature Range: Picking batteries for work in specific temperature zones.

You will achieve better system dependability and service life when you check battery properties before using them for important purposes.

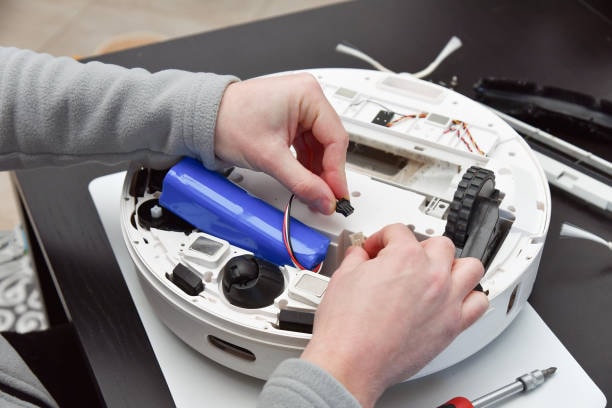

Physical Layout and Connection Methods

The manner in which we place batteries in series impacts how they function plus our ability to maintain and keep them safe. Key considerations include:

- Terminal Accessibility: The locations that control batteries should remain easy to service and check at all times.

- Heat Dissipation: You must place batteries suitably to enable proper cooling of each battery unit.

- Connection Security: Connections need to use rated hardware that can handle the system current and survive all operating conditions

- Vibration Resistance: Mobile power systems need robust battery mounts to protect against movements.

- Weight Distribution:Particularly important in transportation applications

- Environmental Protection: Shielding connections from moisture, dust, and contaminants

A device needs different connection methods to work properly. Options include:

- Bus bars with firm design for high-current electricity distribution systems

- Moveable equipment systems need pliable power cables.

- Spring-loaded contacts for consumer devices

- Welded connections for permanent installations

- For high-current works bolt the components correctly with specific torque adjustments

Every connection technique brings special advantages such as performance quality versus maintenance simplicity and material expense. Small amounts of connection resistance create significant power loss and raises temperatures when handling high levels of electrical current.

Larger battery systems have segments with isolating disconnect points which help technicians safely fix problems in one section without risking a short circuit that could break the whole power system.

Safety and Protection Systems

Overcurrent Protection

A serial battery setup must include protection equipment to shield it from too much current that could melt or catch fire. Common overcurrent protection devices include:

- Fuses act as temporary safety measures that disconnect power when electrical flow reaches their programmed rating.

- They are resetable devices that automatically disconnect power when overcurrent exceeds their ratings.

- Digital Current Control Devices Monitor Electricity Flow Through Measures That Block Current Safely

- Thermal Cutoffs stop power flow when temperature reaches dangerous marks

- PTC elements act as resettable parts that become more resistant when they get too hot during current overloads.

You should pick devices based on the battery terminals maximum safe current capacity and put them in place directly at the terminals. Overcurrent protection devices must meet their assigned rating correctly to do their protection job properly.

- Normally functioning equipment may cause power interruptions if the heat sensors are too ineffective.

- When the protection scales beyond its size it will not activate in time to prevent damage

In electrical security networks that feature several inputs and outputs we place several protection ranks with lower voltage devices monitoring small parts and more capable devices watching groups of wires and the power supply.

Cell Balancing Systems

Several battery cells need voltage regulation when linked in series. Repeated charging of battery cells will make cells become out of alignment which causes some to charge too slowly while others charge too quickly.

Modern battery management systems employ several balancing approaches:

- Passive Balancing: The system applies resistors to naturally release energy from cells that store more charge than others

- Active Balancing: Transferring energy from higher-charged cells to lower-charged cells

- Monitoring Systems: The Monitoring System Checks Battery Cell Voltages to Spot Imbalances Before They Become Severe

- Charger Control: The charger manages its settings through individual cell conditions.

Passive balancing produces heat when it functions to lower charges without moving energy. Active balancing process runs better but demands harder electronic setups. Consumer devices use basic battery leveling whereas larger systems work best with active monitoring.

Balancing systems typically activate:

- During charging cycles

- The approach uses downtime to restore cell balance automatically

- The system responds as specified when voltage differences rise above specific set values

Lithium-ion batteries need cell balancing mainly because cell mismatch can pose safety risks and cut battery durability.

Temperature Management

High temperature and low temperature affect important battery features in arrangements where batteries are connected end to end. Heat speeds up battery chemical processes and creates three major safety risks.

- Reduced lifespan

- Increased self-discharge

- Thermal runaway (particularly in lithium chemistries)

- The liquid from flooded battery cells leaks out when exposed to heat.

- Increased internal pressure in sealed batteries

Effective temperature management strategies include:

- Spacing: Providing adequate airflow between batteries

- Our cooling system uses fans or hydronic computers to manage heat during powerful battery discharges.

- Batteries include temperature sensors that identify heat zones.

- Our system decreases power flow rates during battery runs that reach high temperatures.

- Insulation: Protecting batteries from extreme environmental temperatures

- Thermal Modeling: Predicting temperature behavior under various operating conditions

Temperature monitoring should include:

- Ambient temperature around the battery system

- Organizations watch battery surface temperature most closely at terminal points.

- The battery shows its own core temperature through sensor tools.

- Temperature differences between cells help show battery health problems.

In outdoor extreme settings separate insulation or climate control systems must be added to keep batteries at their required temperature range.

Common Challenges and Solutions

Voltage Sag Under Load

It is normal for batteries in series to lose voltage when they deliver significant power to connected devices. The connected batteries experience a shared voltage decrease when handling current because their internal resistances match the flowing load.

The voltage decreases steadily through each battery in a string leading to insufficient watt hours for equipment functions. The voltage reduction happens according to Ohm’s Law’s rule.

V<sub>drop</sub> = I × R<sub>internal</sub>

The total response depends on current level and the connection of all battery internal resistances.

Solutions to this challenge include:

- Oversizing Battery Capacity: When loading a system higher capacity batteries with low voltage drop values

- Adding Buffer Capacitors: Putting buffer capacitors next to the battery bank can steady power levels when there is power surge

- Employing DC-DC Converters: DC-DC converters help keep the output stable when input voltage changes by controlling voltage levels

- Selecting Low-Internal-Resistance Batteries: Battery technology with optimal performance in high-current situations should be picked

- Load Management: We set up soft-start functions across our system to slow down current intake into our system

Main power systems can switch off dangerous circuits naturally when voltage drops severely enough to hurt electrical gear. Sags become less of a risk when the system design works with a broad voltage span.

Charging Complexities lithium batteries

Serial battery charge operations need special solutions that single batteries do not require. The main issues include:

- Each battery needs to reach its proper charge level during charging.

- The charging network delivers the proper power level to the complete string of batteries.

- Our system watches over each battery cell while it is charging to find upcoming issues before problems occur

- Our system changes charging setups when battery temperature levels change.

- Our charging system decreases energy waste during battery charging activity.

The right charging method consists of main stages except these steps:

- Bulk Charging: During bulk charging the battery system receives constant current until it reaches 80% of its full capacity.

- Absorption Charging: The charging stage stays at a fixed voltage with a fading electrical current until completion.

- Float Charging: The battery system works at a low charge level to prevent self-discharge.

- Equalization Charging:Batteries undergo special controlled charging to make all cells strong enough in lead-acid energy storage devices

Modern charging solutions include various methods to achieve the desired voltage :

- Intelligent Chargers: Charging systems that watch each battery cell voltage and guide charging behaviors automatically

- Balance Chargers: Special chargers that charge specific battery cells in series connections form part of their functionality.

- Battery Management Systems (BMS): A Battery Management System uses sensors to protect cells while they charge and discharge through its integrated circuits.

- Multi-Stage Chargers: Charging equipment that uses feedback from batteries to change power settings

When it comes to larger systems a complete BMS installation provides the best solution to control charging processes effectively. These systems talk to chargers to make battery charging work better at any second.

Dealing with Failed Cells battery bank

Serial battery connections suffer from a main weakness where one defective cell can render the entire string inoperable. A single open-circuit battery cuts the electrical flow among all connected batteries. Systems need to be equipped with features that prevent these challenges.

- Bypass Diodes: The battery system works better when diodes run alongside batteries that forward electricity when cells become nonfunctional.

- Redundant Strings: Putting extra serial battery strings next to each other makes the system more resistant to hardware breakdowns

- Regular Testing: Checkups help find defective cells early in their life cycle to avoid full failure.

- Modular Design: Building Programmed Units that Let Technicians Replace Battery Components Fast

- Monitoring Systems:Our monitoring systems find and notify us about battery problems before they lead to failure.

- Hot-Swappable Design: Allowing battery replacement without system shutdown

The straightforward use of bypass diodes to fix power problems brings power reduction and heat control issues along with it. At the moment of a cell failure they shuttled electricity around the remaining components for limited operation at reduced voltage levels.

Certain systems include voltage enhancement electronics that help power the device while waiting for damaged battery cell repairs.

Switching systems that can shift battery connections in critical situations enable the best possible reliability.

Advanced Serial Battery Configurations

Series-Parallel Arrangements battery capacity

In real battery setups both series and parallel connections help us get the specific voltage and desirable charging capacity. These series-parallel connecting methods produce better results in specific applications.

- When one battery cell stops working the other connected cells can transfer power to the circuit

- The system can provide more power through combined current strength while respecting the needed voltage

- Two or more strings connect in parallel to grow the system easily

- Improved Reliability: Distributed stress across multiple cells

- Our capacity planning works with application requirements to create proper system sizes

Common series-parallel arrangements include:

- 2S2P: The system connects two series strings of two batteries each in parallel

- 4S3P: Four batteries in series, with three strings in parallel

- 12S10P: Electric vehicle batteries often use 12 cells stacked together in series and these 10 such groups connected in parallel as 12S10P.

The system uses nSmP setup where n cells create a series chain which connects to m strings in parallel formation.

Connectors should be arranged to balance electricity flow between all parallel circuits properly. Key design elements include:

- Symmetrical Layout: Ensuring identical wire lengths and connection resistances

- Bus Bar Sizing: Providing adequate cross-sectional area for current requirements

- Our Technique Protects Each Battery String from Damage During System Protection Functions

- The system tracks electrical resistance changes that may show upcoming equipment problems

Advanced series-parallel systems use monitoring systems to spread electricity between parallel strings to maintain proper battery load balancing and avoid individual string overcharging.

Battery Strings with Taps connect batteries

The electrical system needs several voltage access points in its series battery setup. The method enables users to obtain multiple power levels from a single battery bank.

A 48V battery bank with four connected 12V batteries in series needs 12V, 24V, and 36V taps plus the full 48V system. Changing the tap positions allows one battery system to supply power to multiple devices requiring different voltages.

You need to think about these aspects when using tapped battery systems.

- Regular discharge control system keeps all batteries in the bank from depleting energy at similar speeds

- Separate Protection: Implementing overcurrent protection for each tap point

- Connected devices remain separated when working with different tap points to prevent electrical connection.

- Designers should divide power use across voltage levels through strategic planning.

- Our charging system lets us maintain an even battery state during unbalanced discharge conditions

Designers take different methods to stop battery cells from discharging unevenly.

- Selecting appropriate times to switch between voltage levels of the system

- DC-DC converters produce lower voltage outputs than direct connection because of their special conversion ability

- Our system distributes energy between battery parts to prevent unequal voltage levels.

- When red cells appear the system will charge each cell separately

Platforms that tap into power supply require this setup mainly in renewable sources and independent power generation.

Modular Battery Systems

In contemporary battery technology industry designers build systems from separate modules that link together in series formation. Each module typically includes:

- Multiple Cells: Often in a series-parallel arrangement

- A complete battery management system integrates all necessary protective and balancing functions into the module units.

- The system monitors and outputs information to the main controller.

- Everyone can easily add or replace battery modules that follow industry-standard connections.

- The module contains its own temperature control methods and maintains thermal stability.

- The control system sends data about operational status and accepts instructions from main controller units.

This approach offers several advantages:

- Simplified maintenance through hot-swappable modules

- Adding more modules becomes simpler when needed.

- Improved fault isolation and system reliability

- Standardized manufacturing and testing

- The system keeps working at full capacity while updating its parts one by one.

- Distributed intelligence through module-level management

Modular design works well in systems that must keep running because it helps teams maintain or enlarge operations while leaving the main system active.

The modules connect using communication methods such as CAN (Controller Area Network), Modbus, or special interfaces to match charging, discharging, and power protection activities between them.

The modular design features prominently in energy storage system production for commercial facilities but also powers electric vehicles as well as backup power for telecommunications networks.

Monitoring and Maintenance

Voltage Monitoring Systems

The state of all battery cells must be checked over time to run a serial battery system properly. Modern monitoring approaches include:

- Individual Cell Monitoring: Measuring the voltage of each cell or battery in the string

- Our system triggers notification when voltage levels reach specific safe limits

- The system records voltage readings at regular intervals to spot how power cells wear out step by step.

- The system lets you check battery status by connecting to remote networks.

- The monitoring system detects electrical differences between cells to locate weak components.

The system converts voltage data to provide accurate remaining battery capacity information.

- The needed monitoring rate depends on the importance of the application.

- Continuous monitoring for critical systems and lithium chemistries

- Regular automatic computer systems verify standard applications work properly

Advanced monitoring systems incorporate:

- Temperature measurement affects how we control voltage use.

- The system processes voltage changes across various loading scenarios.

- Our system evaluates past battery data to estimate future performance and discover upcoming problems

- Integration with building management systems or other facility monitoring

Handheld voltmeters provide suitable measurement options for smaller battery systems. Larger battery systems use automatic monitoring tools that record measurements all day long.

Regular Maintenance Procedures

Performing frequent maintenance helps serial battery systems last longer. Key maintenance procedures include:

- Visual Inspection: Checking for physical damage, corrosion, or leakage

- We verify that each contact point holds strong connections with its correct partner.

- Cleaning: Removing dust and corrosion from terminals and casings

- Testing specific gravity shows if flooded lead-acid batteries need attention.

- A regular test checks how batteries perform while handling workload

- The camera finds hot spots showing link problems or battery heat issues internally.

- We need to check that both cooling systems and airflow pathways stay open for proper performance.

- The safety system tests ensure protection features operate correctly

Maintenance frequency depends on:

- Sealed lead acid batteries demand less maintenance than standard flooded lead acid varieties.

- Run checks regularly at extreme temperatures and in environments with corrosive conditions.

- System importance sets the required inspection schedule for critical systems

- Existing systems need more thorough exams because of their age.

Effective maintenance operations need proper documentation. Comprehensive maintenance logs should record:

- Maintenance staff needs to record both time and date for their actions

- Measurements taken and test results

- Corrective actions performed

- Component replacements or adjustments

- Names of maintenance personnel

- Observations about system condition

A battery system gets serviced according to how it operates plus its environment but also the type of battery chemistry involved in the system. A critical system needs monthly tests and less crucial systems need only quarterly or semi-annual checks.

Troubleshooting Common Issues

Regular examination of serial battery systems helps find the underlying failure source. The battery system maintenance process focuses on these typical issues with recommended testing systems.

- Test each battery voltage to find out which cells weaken the pack power.

- Find high-resistance connections by measuring the temperature of the batteries with thermal imaging tools.

- Check the battery performance under load to spot batteries with limited power capacity.

- Test both charging equipment output and battery response to find the problem.

- Track each cell voltage levels during charging and discharging activities.

- To find resistance problems in connections measure the amount of voltage that disappears between electrical points.

- BMS Malfunctions: Verify communication and sensor functionality

The proper way to find battery problems involves a systematic procedure.

- Gathering system information and history

- Taking baseline measurements

- Isolating components for testing

- Analyzing patterns in measurement data

- Implementing targeted corrections

- Verifying improvements after repairs

- Documenting findings for future reference

Monitoring systems conduct continuous data collection to show hidden patterns during regular checks. Advanced monitoring systems with logging functions make it easier to track systems during inspections.

Detailed measurement data about large systems helps professionals spot problems through changes in the recorded patterns. As systems grow older the recorded data helps us predict specific parts that need replacement proactively.

Battery Chemistry Considerations

Lead-Acid Batteries in Series

People use lead-acid batteries in serial installations because these batteries deliver dependable performance at competitive rates. Special precautions must be followed while linking lead-acid batteries together with a series setup.

- The system must allow the hydrogen gas to flow into the open air from the batteries during charging operations.

- You should monitor electrolyte levels and fill them up again for flooded lead-acid batteries.

- Batteries require temperature control systems that keep the operating temperature within required limits

- Equalization Charging uses limiting overcharges to make sure cells hold equal specific gravity levels.

- The maintenance system removes sulfate crystals from the plates to stop their formation.

- Lead-acid systems need more space and weight allowance due to their size and mass

You can find lead-acid batteries connected in series within these environments:

- Automotive starting systems

- Uninterruptible power supplies

- Golf carts and electric utility vehicles

- Renewable energy storage systems

- Telecommunications backup power

Several lead-acid types possess distinct characteristics when connected in series

- These cells have the lowest purchase cost but need frequent care.

- Absorbed Glass Mat (AGM): Maintenance-free with better vibration resistance

- Gel cells show outstanding durability while fixing total battery power losses.

- This battery variant accepts charges better plus delivers longer cycle service

Although lead-acid batteries deliver less power than advanced technologies they perform well during sudden power surges and have mature recycling methods in place. Because of their affordability they remain suitable for applications that do not need lightweight or small-sized solutions.

Lithium-Ion Series Connections

Series connections with lithium-ion batteries bring specific hurdles that bring valuable advantages to the system. These batteries fit many applications because they store energy intensely and hold it well yet require special handling.

- Each battery cell needs to run within defined voltage windows from 3.0V to 4.2V.

- The system uses advanced BMS technology to keep battery cells balanced.

- Temperature Control and Monitoring Stop Thermal Runaway from Happening

- Our system has backup protection features that guard against electrical surges and high temperatures

- Matches capacity between cells to stop them from reaching dangerous charge or discharge levels

- The system must not let batteries reach extreme high or low charge levels.

Different lithium-ion batteries feature distinct properties when connected in series for power supply.

- Lithium Cobalt Oxide (LCO): High energy density but lower thermal stability

- Lithium Iron Phosphate cells resist heat well and deliver a long lifespan.

- Lithium Nickel Manganese Cobalt (NMC): Good balance of energy density and stability

- The battery composed of Lithium Titanate material performs billions of charge cycles while charging fast.

The strong energy storage capacity of lithium-ion batteries suits them perfectly for these applications.

- Electric vehicles

- Portable electronics

- High-performance energy storage

- Weight-sensitive applications

- Space-constrained installations

Advanced lithium-ion systems come with BMS electronics inside that watch cell behavior at all times and automatically cut power when threat levels rise. These management systems often feature:

- Cell-level voltage monitoring

- Temperature sensors throughout the pack

- Current monitoring on both charge and discharge

- The system checks for separate components to find insulation breakdowns

- Communication interfaces for system integration

Nickel-Based and Flow Battery Systems

Several battery types exist as serial connection options for different applications.

Nickel-Cadmium (NiCd) and Nickel-Metal Hydride (NiMH):

- These batteries withstand overcharging better than lithium-ion

- Can withstand deep discharge cycles

- Users pair these batteries for electricity tools and backup lighting systems.

- To stop memory effect formation batteries need regular complete discharging.

- The system works properly in harsh temperature conditions

- These batteries maintain their voltage performance in most of their operating cycle period.

NiCd batteries continue to serve specific applications when other batteries cannot handle extreme temperatures or rapid discharge rates because of their cadmium environmental impact. NiMH provides a greener option with better energy storage but operates best within cooler conditions.

The flow battery family uses vanadium redox and zinc-bromine systems plus other similar technologies.

- A different design scheme houses energy levels apart from power generation platforms

- Highly scalable for large grid-storage applications

- You can link several devices for power systems needing increased voltage.

- They provide powerful battery functionality over many years but deliver less stored power.

- You can expand electric power output by adding more electrolyte.

- The technology includes built-in thermal regulation by moving electrolyte through its system.

Flow batteries deliver outstanding benefits to systems that store electricity for long periods at a stationary location. Their design structure lets you customize the system elements independently of one another.

Sodium-Based Batteries:

- This battery technology works either at hot sodium-sulfur temperatures or at room sodium-ion conditions.

- The system stores a large amount of energy using simple material types at low cost.

- The technology offers excellent battery life when paired in multiple units

- Feature inherent thermal management requirements

- Present unique safety considerations due to reactive sodium

Different chemistry options require trade-offs between safety aspects and energy storage performance. The best selection depends on how you want to use the battery.

Future Trends in Serial Battery Technology

Smart Battery Management Systems

Modern battery management technology is making serial battery systems better. Next-generation BMS features include:

- The technology learns from past data to detect battery problems before they happen

- The battery management system manages separate charge and discharge settings for every single battery cell.

- Using wireless technology replaces the manual links that monitor points need to function.

- Our system merges battery data from different storage units to help users compare results

- BMS systems can learn from real-life usage data which enables them to modify their management techniques automatically.

- We analyze performance patterns to perform maintenance before a defined lifespan ends

Smart management systems use advanced semiconductor technology and processing power to create complex battery control systems.

- Cells with problems get disconnected from the circuit through electronics instead of mechanical methods.

- The system controls charging settings by measuring how each battery reacts to charging.

- The system adjusts performance quality now to preserve long-term battery lifespan.

- Our system finds regular usage patterns to create better charging setups for these patterns.

With advanced systems these operating conditions safely direct battery power through the serial connection and deliver up to 40% more runtime compared to regular management controls.

Edge computing built into battery management systems performs extensive data processing locally which enables users to employ these systems in both remote and mobile battery powered applications.

Integration with Renewable Energy

Supplier systems containing several batteries now require serial battery connections for renewable energy solutions. Emerging trends include:

- DC Microgrids: Creating efficient direct connections between solar arrays, batteries, and DC loads

- Hybrid Storage Systems Use Multiple Battery Kinds Connected in Series to Deliver Best Results

- Distributed battery networks operate together as one centralized power source under Virtual Power Plant technology.

- The power grid obtains storage from unused electric vehicle battery packs through Vehicle-to-Grid Integration.

- Solar-Direct Charging: Connecting PV panels directly to battery systems without intermediate conversion

- Bifunctional Inverters provide instant switching between standard grid tie-ups and separate electrical networks

The systems need powerful serial linked battery packs that plug straight into power conversion devices for renewable energy sources.

Renewable energy systems with battery storage need new methods of monitoring battery groups.

- The system uses forecasted weather data and predicted power sources to hold back battery power.

- Our System Controls Flow of Power from Multiple Generation Sources through Storage into Multiple Power Points

- A battery system monitors and corrects grid frequency problems found in areas that use extensive renewable energy

- The battery control system links up into utility demand response projects while matching battery power with grid needs

More advanced serial battery systems will develop to manage battery flexibility alongside parallel configurations s areas install more renewable energy systems.

Emerging Battery Technologies

Battery developers aim to develop fresh power storage frameworks that will drive different serial connection applications.

- Solid-State Batteries: Offering higher energy density and improved safety for serial connections

- Sodium-Ion: Providing lower-cost alternatives to lithium with similar connectivity options

- Aluminum-Ion: Promising faster charging capabilities in serial configurations

- Battery systems go beyond usual designs by embedding cells directly into building materials and this approach changes how electric cells are linked up.

- Lithium-Sulfur: Potentially delivering higher energy density at lower cost

- Silicon Anode Technologies help rechargeable batteries store more energy without needing new system connections.

New technology gives serial connections natural benefits including:

- The new cells allow safer thermal performance which decreases cooling needs and creates easier thermal handling.

- Controller can balance voltage levels better during power discharge actions

- Integrated Cell Balancing: Building balance functionality directly into cell chemistry

- Using cells with high voltage lets us lower the number of cells needed to drive power-hungry equipment.

- Enhanced Safety Features: Allowing for simpler protection systems with fewer components

Research results moving into market production will bring major changes to serial battery system designs over the next ten years.

Case Studies: Serial Battery Success Stories

Electric Vehicle Battery Architecture

Modern electric vehicles prove how advanced serial battery technology improves vehicle performance. The rechargeable battery pack in Tesla Model 3 is arranged in a 3,976 cell structure that places 96 series strings of 31 parallel cells.

This architecture delivers several advantages:

- With 350V nominal voltage the system works well in motor applications.

- The distributed small cell design makes thermal management more effective.

- Parallel paths work as backup systems to maintain operations.

- You can replace specific battery modules without interrupting the entire unit when they show signs of damage.

- Standard specifications make it possible to automate the production process for battery cells.

The battery pack uses different levels of control at separate points to manage performance.

- The battery cells emit precise voltage data to observers within the system

- Module-level control for temperature management

- Pack-level coordination for overall system optimization

This successful arrangement has transformed the electric vehicle market making most manufacturers duplicate this cell structure design.

Recent innovations include:

- The auto body uses battery technology as a vehicle chassis structure.

- Packed battery cells without module construction provide increased energy density at their core.

- 800V architectures for faster charging and higher efficiency

These highest-quality serial battery products combine top performance features with built-in safety controls to make them easy to manufacture at scale.

Grid-Scale Energy Storage Implementations

Major electrical grid storage systems incorporate numerous battery cells linked in series to deliver high enough power for grid hookup. In Australia the Hornsdale Power Reserve battery system stores a massive amount of electricity to power 150MW for 194MWh by linking thousands of batteries.

This solution contains these main elements:

- Standard battery building blocks can be serviced individually throughout the modular structure

- Multilevel Monitoring: Tracking performance at the cell, module, and system levels

- Active Thermal Control: Maintaining optimal operating temperatures across all batteries

- Our system optimizes power flows across the battery bank to support grid availability

- Redundant Protection: Implementing multiple layers of safety systems

- Scalable Architecture: Allowing for capacity expansion over time

The system offers several essential grid services through its design.

- The power system needs frequency control to remain stable.

- During times of peak usage the system lowers customer need for better service delivery.

- The energy system stores electricity during cheap times to find market opportunities later.

- Power grids can use our system to properly store solar and wind energy during production surpluses.

By showing that substantial battery arrays function well with grid systems the project confirmed these systems’ applications for power regulation and renewable energy utility. Multiple battery systems have been deployed globally to keep growing in size and technology complexity.

Installed battery storage equipment performs well and proves profitable which boosts industry adoption while driving fresh developments in battery control technology.

Off-Grid Solar with Battery Storage

People use serial battery setups to create reliable standalone power systems. A remote cabin power system usually includes these system components:

- Solar Array: Multiple panels generating 18-24V DC

- The charge controller adapts solar input changes into the proper battery charging voltage.

- We use four 6V deep-cycle batteries installed in series to create a 24V electricity system.

- Inverter: Converting 24V DC to 120V AC for conventional appliances

- When energy runs low our system will deliver the necessary power to essential loads first

- Our Monitoring Tools Show System Working Conditions and Productivity Facts

This system design supports power conversion efficiency by selecting suitable wires and reduces battery capacity requirements despite nighttime and shade conditions. A 24V configuration provides safer power than high voltage systems and achieves better energy efficiency than 12V systems.

Serial battery connections show many key benefits in the system design.

- The voltage increase lets you use thinner conductors for transmission

- More input voltage usually tones up the conversion efficiency in the inverter.

- You can expand system capacity by joining extra 24V strings side by side.

- Standard 24V system components can be easily obtained for system expansion.

This power system design has shown success in both remote vacation destinations and scientific research facilities plus telecommunications equipment and power grid programs all around the world.

New technical solutions now appear in this application:

- A system that controls how energy moves between generation storage and end users automatically

- Smart Load Controllers watch for times when the electricity system produces its most power to run power-hungry devices

- Remote Monitoring capabilities for system optimization without on-site presence

- System hybrids work with both wind power and small-scale hydro sources.

Practical Implementation Guide

DIY Serial Connection Projects

Many people choose to build serial battery systems through different projects that teach practical skills.

- Building an emergency UPS system involves stringing four 12V sealed lead-acid batteries into a single 48V buffer bank with an inverter.

- Portable Power Station: Building a lithium-ion-based power pack with 18650 cells in a 4S configuration

- Install three AA NiMH batteries in series connection to power a small solar panel charger.

- Electric Bicycle Conversion: Creating a 36V or 48V battery pack for an e-bike drivetrain

- Ham Radio Field Power: Assembling a lightweight, high-capacity battery system for portable radio operation

- Making an 18V or 20V lithium-ion battery pack that works with workshop tools using cordless power systems.

These are the basic requirements to make your own electronic projects work successfully.

- Security Comes First – Include All Necessary Fusing and Electrical Protectors

- Use insulated tools made to handle specific electrical levels with right connection units

- Verify every battery’s performance before creating a series connection.

- Documentation: Recording the system design and component specifications for future reference

- Build up your projects step by step after learning the basics

- System power levels should be estimated correctly before you plan power capabilities.

Beginners typically make these errors when learning battery systems:

- Proper wire selection needs improvement because extra heat builds up from voltage loss

- Missing protection components such as fuses or circuit breakers

- Batteries do not perform well when they receive improper cell connections.

- You should not assume too little air flow for your battery type

- You should not disregard the temperature impact on battery performance.

People new to DIY solar should begin their projects with lower voltage systems that provide experience and safeguard against safety problems.

Scaling Considerations

When serial battery systems expand larger power becomes more challenging to manage through these key criteria:

- Connecting the electric cells properly across the complete system prevents power loss during operations.

- More advanced voltage measurement tools should be used for accurate reading as the number of cells grows.

- The system needs to handle effective temperature control for power arrays that produce significant heat.

- The high-voltage sections need dividing to make maintenance operations safe.

- The installation must meet all electrical standards that apply when working at higher voltage levels.

- Physical Reinforcement: Providing structural support for the increased weight

Several steps need to be taken to design bigger setups after basic system projects.

- Compliance with electrical codes and standards

- Professional-grade protection devices and enclosures

- Redundant safety systems and fail-safes

- Regular professional inspection and maintenance

- Fire suppression systems for larger installations

- Staff members who work on the system must complete safety instruction programs.

Strategies for successful scaling include:

- Building interchangeable units that follow a common design pattern

- Hierarchical Protection: Implementing multiple levels of overcurrent protection

- Large systems are divided into smaller operating sections as part of a segmented approach.

- Using established rules for documenting all system information consistently

When growing from small to large battery systems you must convert from regular components to specialized power system equipment.

Professional Installation Best Practices

The procedures for installing battery systems in commercial or crucial setups require professional standards as follows:

- System Documentation: Creating comprehensive wiring diagrams and component specifications

- Mark the equipment properly to show voltage patterns, electrical orientation and switch positions

- Accessibility: Ensuring maintenance access to all components

- Redundancy: Implementing backup systems for critical monitoring and protection functions

- Our company trains employees about correct safety methods for system operation

- Commissioning: Properly testing all aspects of system operation before handover

- We create a system for routine equipment servicing and maintenance operations

Professional installers include various other security options during service

- Remote monitoring and alerting systems

- A system automatically protects large spaces from fire danger

- Lockout-tagout provisions for maintenance safety

- Performance analysis and reporting tools

- Environmental controls for temperature and humidity management

- The system includes measures that block unauthorized people from getting inside

Quality assurance procedures should include:

- Torque verification of all connections

- Thermal imaging of connections under load

- Insulation resistance testing between battery circuits and ground

- Our system performance checks depend on load tests.

- We check all documents to make sure that the information is exact and complete.

By following these standards microgrid operators protect personnel while making their system perform better and last longer.

Environmental and Sustainability Aspects

Recycling Serial Battery Systems

Most people encounter issues while getting rid of serial battery power supplies. Proper recycling approaches include:

- Our team disconnects battery modules from their serial assembly to process them safely.

- Our process finds lithium cobalt and lead metals to reuse them from the discarded batteries.

- Repurposing: Using batteries with reduced capacity in less demanding applications

- Our team takes care to handle hazardous components through appropriate neutralization methods

- Circular Economy Integration: Designing batteries with recyclability as a primary consideration

- Material Tracking: Maintaining chain of custody throughout the recycling process

Different modern recycling processes help extract battery materials better

- A hydrometallurgical process recovers more than 95% of materials from batteries.

- New automated machine systems help experts process many batteries at once

- Methods that directly recycle cathode parts at their original form to boost new life of battery materials

- Bacteria breakdown processes help separate metals from battery waste in biological leaching systems.

- Thermal treatment systems identify parts through their melting temperatures

Battery recycling production costs depend heavily on the type of battery material used.

- Many factories already recycle lead-acid batteries at a very high success rate of more than 99%.

- Companies now extract lithium-ion batteries using effective processes that create more money for operations.

- Flow battery technology restores electrolyte health instead of performing complete recycling tasks.

- The nickel-based processes have long been used in metal extraction while remaining useful today.

When we create serial battery systems and plan for recycling they will save both the environment and lower recycling costs.

Second-Life Applications

Used-up batteries that used to power high-performance systems can still deliver enough power for basic efficiency needs. Serial batteries head toward multiple uses beyond their origin when they reach the end of their first life.

- Stationary Energy Storage: Repurposing EV batteries for home or commercial backup power

- Aged batteries help maintain electricity quality by absorbing power swings and keeping frequencies balanced

- Microgrid Support: Providing energy storage for small-scale power systems

- Educational Systems: Supplying batteries for teaching and research applications

- Battery cells become available for lighting systems and Internet of Things devices after their main use ends

- Emergency Support Systems: We set up UPS systems to power equipment that does not require instant access

To use batteries for their second lives requires several important steps.

- We change the serial wire connections to work with different power system specifications.

- Implementing more conservative operational limits

- Our amount of battery outage tracking will improve to handle changes in battery performance over time.

- Periodic reassessment of capacity and performance

- Our team harmonizes cell strength distribution throughout the storage life span.

- Safety controls need current adjustments to work as expected in this new product market.

Specialized businesses in the field reconditioned battery cells to build optimized battery packs for secondary life applications.

This strategy uses existing battery resources longer to build battery technologies with more sustainable practices.

Carbon Footprint Considerations

Serial battery systems generate environmental consequences before and after their functional lifetime. Key considerations include:

- Building the battery pack structure and its components requires energy to manufacture them.

- The serial battery system affects charging and discharging process performance to make operations more efficient.

- The total useful life span depends heavily on chosen design decisions

- The energy used and resources needed to process batteries at their end of life cycle

- Transportation Impacts: Environmental costs of moving heavy battery systems

- Manufacturing processes need minerals and chemicals that respect the planet and its resources

Making serial battery systems operate better for our planet requires several actions.

- Choose batteries that produce less carbon during their production phase

- Our systems use engineering to create high-performance products that last longer

- Initiate battery monitoring systems to protect against product breakdowns before their time

- Our company prepares now for future battery reuse

- Our business depends on getting parts from manufacturers who make products in eco-friendly ways

- Building battery plants near their usage locations reduces transportation needs

LCAs display that most battery environmental impacts arise from the production process. Effective serial connection work and support boost battery usage to save the most on environmental impact.

A power system’s sustainability depends on its power storage ability to exceed how much carbon it used in manufacturing over time. When you plan serial battery connections properly they can shorten the return on investment period by making the system work better and last longer, keeping both the voltage and capacity in check .

Conclusion

Modern power storage systems use serial battery links to provide flexible voltage based on various market needs. Serial battery arrangements support basic electronics to power electric vehicles and adjust power outputs for electricity grids thanks to their versatile design.

All applications use serial batteries by adding voltages while keeping capacity and safety requirements steady. The key advantages of serial connection in batteries remain strong as battery technology advances.

A serial battery system works best when you follow these essential success factors.

- Understanding fundamental electrical principles

- Selecting appropriate battery chemistries

- Implementing effective monitoring and protection

- Maintaining proper operating conditions

- We plan all stages of system life

The rise of energy storage systems in electric power demand pushes research and development in serial battery technology adaptation. Energy storage systems linked to consumer devices and power grids enable power flexibility by managing and supplying electrical power at necessary times and places.

Several trends will direct the path serial battery systems will take in the future. Recent battery control systems make the technology work better and stay resilient in its performance. New battery materials will give power system upgrades performance benefits. Renewable energy connections are pushing serial high-voltage battery systems to advance further. The practice of linking batteries in series will keep serving as an essential component in electrical energy storage systems.

The technology of serial battery connections needs designers and engineers to learn its working patterns to build safe and efficient storage solutions. Batteries using serial connections will depend for their growth as we move toward electric power sources and renewable energy systems.