Meta Description: Find out design principles of resistor load bank, testing applications, and implementation strategies. Professional guide on types and specs and best practices to achieve best performance.

What is a Resistor Load Bank and Why Does It Matter?

A resistor load bank is an important component and an important electrical test equipment that represents real electrical loads, to put power supply, generators, and electrical systems under controlled tests. These equipment involve resistive elements to develop a predictable electrical load that would enable engineers and technicians to confirm the performance, capacity, reliability of the system before it is used in critical applications.

Load banks are the foundation of electrical system testing, which affords a secure and controllable arena through which to exercise power generation equipment, UPS systems, battery banks, and other electrical infrastructure. Electrical systems are unlikely to work properly during essential operational processes unless subjected to adequate load tests, so they can also cause downtime that is detrimental to both the finances and safety of an organization.

Understanding Different Types of Resistor Load Banks

AC Resistive Load Banks

AC resistive load banks are specific to test alternating current power sources. these units produce only resistive loads that can consume real power of the source and thus they are useful in testing of generators, transformers and AC power sources. These load banks use the resistive components that are used to change the electrical energy to heat in a stable and predictable load characteristic.

DC Resistive Load Banks

DC load banks Resistive load banks specialize in direct current (DC) loads, often found in battery testing, DC power supply testing and fuel cell testing applications. Such units need to be able to cope with peculiarities of DC power like constant current versus constant voltage relations, and thus these units are vital in verifying DC infrastructure in telecommunications and data center as well as renewable energy applications.

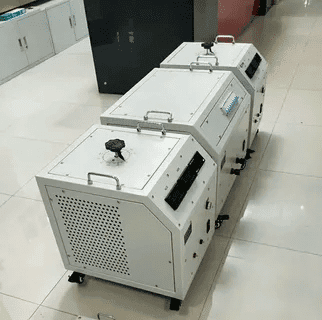

Portable vs. Stationary Load Banks

They are available in portable load banks that can fit field testing or temporary installations. These units are generally lighter and small in size, and thus they are applicable in on-site tests of generators, and the maintenance procedures, and emergency cases. Fixed load banks are, however, meant to be permanently installed and have bigger power ratings with better ability to dissipate heat.

Key Design Principles for Resistor Load Banks

Power Rating and Capacity Planning

The main element of a resistor load bank design commences with ascribing the equitable rating of power. This entails computing the load maximum requirements including the factors like levels of voltage, the current capacity and the test duration. Continuous and peak power needs should be considered by the engineers so that the load bank can be able to accommodate different testing conditions without degrading the performance or compromising on safety.

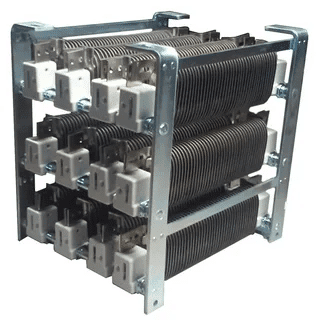

Thermal Management Systems

Heat management is an important role in the resistor load bank design. To apply electrical energy, converting it to heat, then the cooling systems need to be strong to avoid overheating and to ensure stable operation. This will involve drawing good heat sinks and a venting system and possibly forced air or liquid cooling also depending on power rating and on the application requirements.

Electrical Safety and Protection

The concept of safety has to be inculcated into the whole design. They comprise having proper grounding systems, overcurrent protection, means of emergency shutdowns and having proper electrical enclosures. It has to adhere to appropriate codes and standards of electricity to make it safe to the different environments within which it is to operate.

Essential Components of Resistor Load Bank Systems

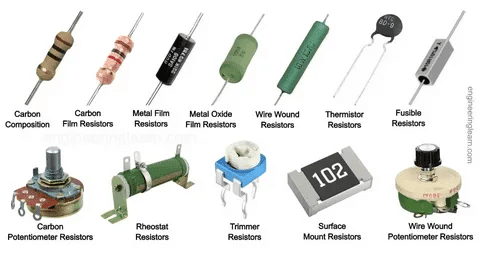

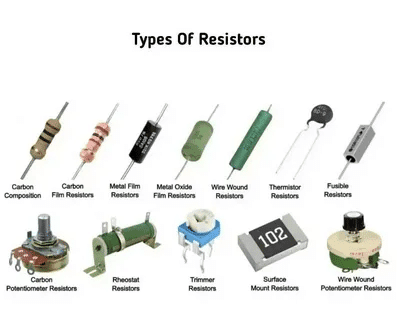

Resistive Elements Selection

The most important part of resistor load bank is its resistive components. These elements have to be well chosen considering their power rating, values of resistance, temperature coefficients and stability. Wire-wound resistors, thick-film resistors and special high-power resistive elements used in load banks are common resistive elements.

Control and Monitoring Systems

More advanced resistance load banks have some complex control systems that enable accurate load regulation and observation. Such systems usually have digital controllers, user interfaces, remote monitoring and data logging features. Control system should offer accurate load control as well as give instantaneous feedback to the system.

Protection and Safety Mechanisms

Safe functioning requires comprehensive systems of protecting. These are temperature monitoring, overcurrent protection, ground fault detection and emergency shutdown. Such mechanisms should be made such that it responds rapidly to fault conditions together with delivering obvious indication of the state of the system.

Testing Applications and Use Cases

Generator Testing and Commissioning

Resistor load banks are critical in the testing of generators whereby a technician can test the performance of the unit under different load conditions. This involves testing on varying power levels, testing of voltage regulation, frequency stability, and reliability in the performance of the system. Frequent load bank testing will give confidence that generators will work when the real power is lost or taken off because of an emergency.

UPS and Battery System Validation

Battery banks, Uninterruptible Power Supply (UPS) and battery back-ups must be tested regularly to be able to give power at the time it is demanded. Load banks Resistor load banks can be used to simulate the controlled conditions required to test battery capacity, discharge behaviours and overall system performance. Testing is essential to sustaining power systems in mission-critical data centres, hospitals and other buildings.

Power System Commissioning

Electrical installations which are new are to be subjected to a thorough test before it is brought into service. The ability to test power distribution systems, to verify protective device coordination, to verify system proper operation at numerous load conditions, etc. is accomplished using load banks. This is needed as part of commissioning the process to ensure that the problems can be spotted before they impact on the real operations.

Specifications and Performance Characteristics

Voltage and Current Ratings

Specification of the voltage and current ratings is central in design of load banks. Such ratings should correspond with the tested systems but they should include reasonable safety margins. Take into account the voltage regulation, current carrying capacity and the capability of withstanding transient conditions which might be developed during the testing.

Load Resolution and Accuracy

Controllability and measurement of load conditions is critical to any good test. The modern load banks must be able to give minute scale of adjustment of the load and precision of measurement of the electrical parameters. Such accuracy provides an opportunity to study the performance in detail and detect even minor performance problems.

Environmental Considerations

Load banks have to be built so that they perform under different environmental conditions. These entail exposure to extreme temperatures, changes in humidity, altitude risks, and the risk of exposure to the extreme industrial environments. Correct environmental design results in reliability in performance and the life of the equipment.

Implementation Best Practices

Installation and Setup Guidelines

Safe and efficient operation of load banks needs proper installation. This covers; proper ventilation to release the heat and proper electrical connection, proper grounding and adherence to local electrical code. Maintenance and operation can also be considered in a way that the installation is safe to the personnel.

Maintenance and Calibration Requirements

A regular maintenance and calibration of the load bank is needed to ensure the compatibility and accuracy of the load bank. They are periodical checks of resistive elements, the accuracy of control systems, cleaning coolers and renewal of worn out elements. Having a comprehensive maintenance program can prevent any sudden failure to occur and monitor performance at all times.

Safety Protocols and Procedures

There should be extensive safety guidelines that will be set up upon operation of load bank. This comprises adequate personal protective clothing, lockout/tagout steps of procedure, emergency response planning and personnel training requirement in operating the equipment. Proper procedures can avoid chances of accidents and as well as provide a safe environment during all testing processes.

Troubleshooting and Optimization

Common Issues and Solutions

Being able to do this by learning about some problems that occur with using a load bank often allows optimal operation. They can be issues of being overheated, failure of the control system, failure of resistive elements, and problems in the cooling system. A systematic set of troubleshooting guide can assist in diagnosing problems and getting faster fixes to maximize test time with minimal downtime.

Performance Optimization Strategies

The performance of load bank can be optimized by fine-tuning of other parameters of the system. This involves the modification of cooling systems to ensure a perfect temperature control, calibration of systems to maximum accuracy and the uses of preventive maintenance plans. Periodic reviews of performance lead to the creation of an opportunity of improvement.

Future Trends and Innovations

Advancement in materials science, digital controls, and system integration can be an improvement to field of load bank technology. The new trends are related to smart load banks having more monitoring features, higher efficiency due to enhanced thermal management, and the incorporation with automated testing systems. Such inventions will help increase the testing capacity as well as save on operational expenses.

Logistics and Supply Chain Considerations

In seeking supply of resistor load banks and other associated products; it is important to use qualified logistics suppliers, in order to realise quick deliveries and cost-effective proposals. Shenzhen Guanwutong International Freight Forwarding Co., Ltd. (GWT Worldwide) is a global freight forwarding and supply chain solution provider, and provides an overall logistics solution based on air freight, sea freight, China-Europe rail freight and international express network. Second, their experience in custom clearance, warehousing and shipping of specialized industrial equipment will guarantee the safe and efficient delivery of load bank components and systems at a timeline and within budget goals supporting their project.

Conclusion

Substantial resistor load bank design is essential to the reliable test and validation of electrical systems. Through adherence to the defined principles of design, proper safety precautions and anticipated use of the load bank system over long periods, engineers will be able to come up with reliable, safe and accurate load bank systems that will serve as steady-state testing facilities. The costs of developing proper load bank design are rewarded when the system runs more reliably with fewer shut downs due to load bank failure. Certain electrical systems which have a load bank at their center produce more safety in operation too. With more electrical systems now becoming more complex and critical to today operations, the need to have well-designed load bank testing equipment cannot be underestimated and thus forms a paramount part of the total electrical testing strategy plan.