Battery circuits play a vital role in countless electronic devices and systems, especially when connecting batteries together, such as portable gadgets as well as large renewable energy sites. Properly connecting batteries in circuits in the right way—in series, parallel or both, including connecting batteries in series ensuring positive terminals are correctly aligned —helps achieve better results, higher safety and better efficiency. How the batteries are set up in a system can change both its maximum voltage, capacity and the length of run time which then impacts both how the device works and its life span. People involved in any work with batteries—engineers, hobbyists or others—need to have this foundational knowledge.

Most of the time, batteries are not used strictly by themselves to provide power. In fact, a number of batteries in parallel are arranged to offer the voltage and current expected for specific loads. The designer picks series or parallel because of what they want to achieve with the powered device. All configurations provide different benefits and challenges when it comes to energy delivery and control within the circuit. Knowing these relationships, especially those concerning connecting batteries in series, helps people make better and smarter battery systems.

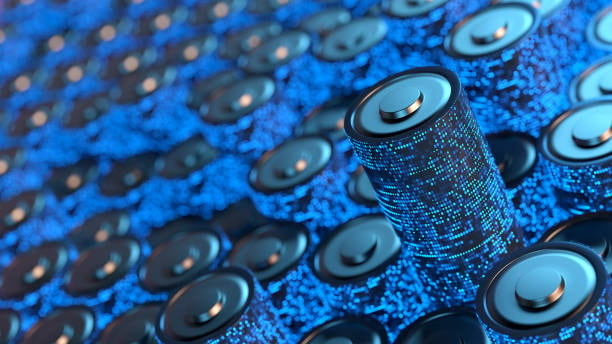

Modern technology such as electric vehicles, renewable energy storage and small electronics, often uses lithium battery circuits. As we ask for better performance and increased life from batteries, learning how to join them safely to create a battery system is now more important. This introduction prepares us to explore the specifics of series and parallel battery circuits, their habits and useful tips for their use.

Basic Principles of Electrical Circuits

Basic rules about electrical circuits must be understood first before working on battery-specific setup. Simply put, an electrical circuit is built from a source of power, a conductor for electricity and a device that drains electrical energy. These circuits use only voltage, current and resistance as main quantities. Voltage is the motivating force behind electrical charges in a circuit, current is the motion of charges and resistance slows that motion. To understand circuit behavior, Ohm’s Law which connects these three (V = IR), is fundamental.

Voltage and current are keys in battery circuits, as they decide the maximum amount of power going to the load and contribute to the total capacity . Voltage and current are used to calculate power and controlling these well is key to better performance from battery-powered machines, especially when considering the capacity rating of each battery involved . Discovering how these electrical quantities change when using multiple batteries wired in series or parallel enables users to forecast the way their system will react in different settings.

In addition, series and parallel circuits have uses with more than just batteries; they can also be applied to resistors, capacitors and similar components, ensuring proper connection of positive and negative terminals . As a result, people have confidence when fixing, creating and enhancing electrical systems. Learning the basics is important for both producing a battery bank and preventing harm, avoiding damages and improving energy use in various applications.

What is a Series Battery Circuit?

A series battery is set up by linking the positive end of one battery to the negative terminal of the next. With these batteries in parallel, all the voltages are added together but the total current available is still equal to that of one battery. If you combine two batteries of 3.7-volt in series, you get 11.1 volts for the output, but the current rating is still the same. Therefore, serial connections are often used when a lot of voltage is needed.

What makes series circuits unique is that each battery in the chain gets the same amount of current. When one battery stops providing power or pulls out of the circuit, When one battery stops providing power or pulls out of the circuit, the whole combination of remaining batteries no longer functions. Also, a weakest battery can hinder how well the group performs due to the need for all batteries to cover the same current output. Making sure batteries are harmonized in series and that batteries connected in parallel are configured properly is necessary to avoid any damage and ensure like discharge speeds.

These types of battery circuits are found in flashlights, electric cars and portable power tools that need a high voltage to drive the motors or operate their electronics well. But since the voltage is greater when electricity passes through diodes, users need to treat them carefully. Series circuits are typically used, along with balancing and battery management systems, to achieve higher system voltage while the parallel configuration helps keep track of every cell’s battery strength and voltage.

What is a Parallel Battery Circuit?

A battery in a parallel circuit is placed side-by-side, joining the positive dots and the negative dots with the purpose of making several ways for current to flow. Unlike series circuits, where all the voltage appears across the batteries, in parallel the voltage is the same as a single battery, but the amount of current allowed by all batteries adds together. If three batteries of the same capacity, 3.7-volt, are connected in parallel, the whole system will draw one current three times as high, allowing the batteries connected to run for a longer total time.

The current in parallel battery circuits splits, so the load can be powered by multiple batteries together, allowing for less voltage drop across the system . It is preferable in applications that need to run longer than to have a higher voltage. The longer running time between charges is achieved because the device’s capacity has increased. If one of the batteries fails, the others can still supply the current, so we have added redundancy and greater reliability.

While parallel connectivity helps, you need to make sure the batteries are similar to avoid each getting charged differently. Charge differences in a battery can cause problems that lower battery life or might create safety concerns if they do not have the same capacity . Keeping these conditions away often requires using battery management systems to regulate the cells. In power banks, solar power stations and backup systems for power, parallel circuits are preferred due to their ability to consistently deliver current.

Voltage Behavior in Connecting Batteries in Series Circuits

Series circuits are useful mainly because of their voltage behavior which stands out in several application areas. The voltage you receive in a series connection is the sum of every battery’s voltage. The number of batteries you connect in series is matched by an increase in voltage in the same amount. If you join four 3.7-volt lithium-ion batteries, the load will get 14.8 volts which can power gadgets that have higher voltage needs.

The reason this works is that two or more identical batteries, linked end-to-end, create a common increase in electrical potential. Yet, the current the system can carry is always limited by the rating of a single battery, even if the voltage is stronger. Because of this, series circuits are great for running devices needing a higher voltage and a moderate current, including electric motors and LED lights.

Still, voltage characteristics create a few issues as well. When a battery’s charge is low or it’s damaged, the performance of the entire circuit can suffer. Also, since high voltages are used, Also, since high voltages are used with two batteries, special care must be taken to protect against possible accidents. As a result, using a battery management system is necessary in series circuits to safely and reliably maintain the proper voltage.

Current Behavior in Parallel Circuits

A major advantage of parallel battery circuits is how they improve the capacity of the current. When fully charged in parallel, batteries have the same voltage as one battery, however the combined current is the addition of every battery’s current rating. Because of this, parallel arrangement helps batteries produce more current, increasing their amp hour capacity, which matters most for systems that require consistent power or high momentary current.

With multiple paths available, extra current can be drawn by the load, while still preventing any one battery from becoming overloaded. This makes it easier for every cell and helps the battery pack last longer. Besides, having multiple batteries in parallel means that only one has to work; if one fails, the rest still keep the system running.

Yet, problems may occur with parallel circuits if the batteries are not similar enough. When the voltage and charge of each cell are not the same, some batteries in the system may become under stress, discharge too quickly or even overheat. Therefore, battery management systems keep track of the current flowing between the batteries and manage it safely to make operation more efficient.

Advantages of Series Circuits

There are many reasons why series battery circuits are suitable for several applications. The main benefit is that you can increase the output voltage just by adding more batteries together. Therefore, devices that need a lot of voltage do not require costly converters. An important reason why series circuits are so common in electric vehicles, power tools and battery banks is how easily their voltage can be raised, which is crucial for creating an efficient battery system .

They are also useful since their wiring is quite simple to construct and fix when needed. Checking the current through the whole system is simpler because all batteries have identical current. Because the flow is predictable, building backup and management systems for batteries becomes easier.

Also, by connecting battery packs in series or parallel, we can form batteries that match the exact requirements of voltage and current needed. With this flexibility, engineers can plan battery systems that are precise for each power demand. All these advantages are only available when batteries are installed correctly,.

Advantages of Connecting Batteries in Parallel Circuits

Having parallel battery circuits results in several positive changes that make battery-powered systems perform better and become easier to use. The main gain is improved current handling, resulting in more use time due to higher stored energy and a lower applied voltage. For this reason, parallel connections are well-used in solar storage systems, UPS and power banks.

Another advantage is that parallel circuits have redundancy. As soon as one battery cell stops working, the other linked cells will still supply power, making the system less likely to shut down and more reliable. Being able to deliver uninterrupted power matters most in situations where it is needed constantly such as using medical devices or emergency lights.

In addition, it becomes easier to scale systems when circuits are set up in parallel. Getting more capacity from your batteries is easy—just place cells in parallel, without touching the voltage setting. Subdivided parts of a battery pack make it possible to use only the power you need and also let you replace one battery without disturbing the others.

Disadvantages of Series Circuits

Series circuits give users many benefits, but they also have certain disadvantages. A problem is that if a series circuit’s battery fails or comes loose, the entire line will fail to operate. Because of this, series configurations are more at risk of system shutdowns when the cells connected are not well matched.

Another problem is that the batteries in a series must be very similar in capacity. When cells have different capacities or are not charged at the same time, some electricity can be used more which places more stress on a few cells than on others. This might make the battery wear out sooner, so additional techniques are used to keep all cells in good condition.

High voltage in series circuits can make safety a concern. If the correct protective measures and insulation are absent, greater voltage can be very risky. For series battery packs to stay safe and reliable, every detail of the wiring, connectors and protective gadgets must be looked at closely.

Disadvantages of Parallel Circuits

Still, there are situations where parallel battery circuits can decrease performance and threaten safety. Much of the problems come from a current imbalance that happens when the different batteries have different voltages or internal resistances. As a result, some batteries end up sending out more current which can make them overheat or work until they lose power too soon.

Dealing with charging multiple batteries in parallel isn’t always simple. Due to the fact that each battery might be charged differently, advanced battery management systems ensure their charging is done properly and safely. Without good balancing, some batteries might get overcharged, while others might stay too weak which harms how well the battery works overall.

Furthermore, parallel circuits cannot enhance voltage, so they are unsuitable for many higher voltage applications. In order to provide higher voltages, designer often use parallel connections together with series connections which means both voltage and current need careful control and make the design more intricate.

Voltage Distribution in Series Circuits

All the individual batteries in a series battery circuit are connected end-to-end so their voltages add up to give the total voltage. All batteries add their voltage, so three 3.7V lithium-ion cells joined in series give a total of 11.1V. Adding two or more batteries makes high voltages possible without the need for complicated ways to change battery voltages.

Even when those batteries are linked in series, they usually have unequal voltages while in operation. Unequal battery condition, storage or level of internal resistance can trigger partial voltage drops, possibly overcharging or over-draining some cells. Such an imbalance can harm batteries and reduce how long your battery pack lasts.

This issue is managed with battery management systems (BMS) which oversee and equalize the voltages of each cell in a row. These systems are designed to handle the charge and current, so every battery in the pack stays at safe voltage, looking after the entire battery and making it last longer.

Voltage Stability in Parallel Circuits

Batteries put in parallel are able to keep the voltage constant, the same as a single battery. Even with additional batteries, the voltage does not change and so all batteries provide a safe and reliable power level. For this reason, parallel circuits are chosen for applications that use low voltage and high current.

As a result, it is crucial in parallel battery systems that batteries have the same voltage and state of charge. Whenever the voltages of batteries are unequal, current can flow in one direction, causing problems or less efficient use of energy. Because of this, the art of matching and monitoring PaDs closely is important.

A vital part of this is battery management systems which make sure voltages do not fluctuate and the batteries are used equally. Thanks to these systems, batteries can’t flow too much current between each other, are defended from getting either too much charge or too little and have better safety and performance as a whole.

Impact of Internal Resistance on Lithium Battery Packs

How well both series and parallel battery packs function is powerfully influenced by internal resistance. All batteries have resistance that results in both drops in voltage and the generation of heat when current passes. The total resistance in a series circuit increases, thanks to added internal resistance and this reduces how much energy can be used, especially when considering the cells connected in the circuit .

Because of internal resistance, bottlenecks can exist in how current is shared among batteries. When you have cells with different resistances, the one with higher resistance usually does not supply enough current to complete the charge, unevenly discharging and overheating the remaining cells. This condition is risky and can decrease how long your battery pack will work.

They overcome internal resistance by carefully selecting batteries and using battery management to watch battery temperature and current usage across all cells connected . Their approach helps the system to operate steadily and makes the battery packs last longer.

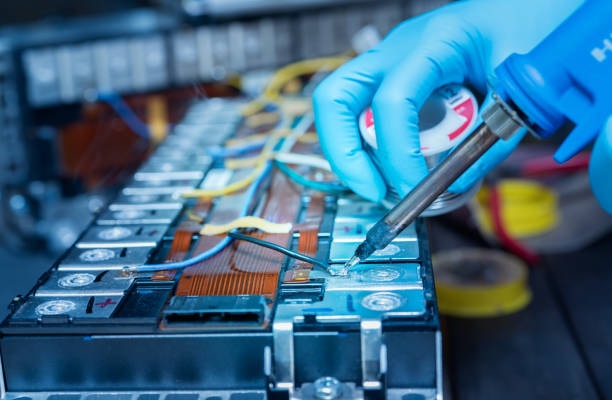

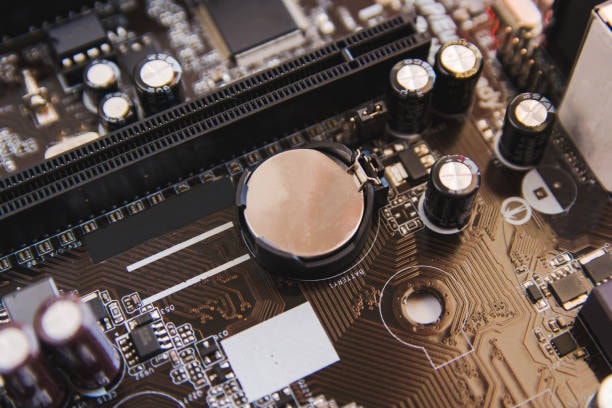

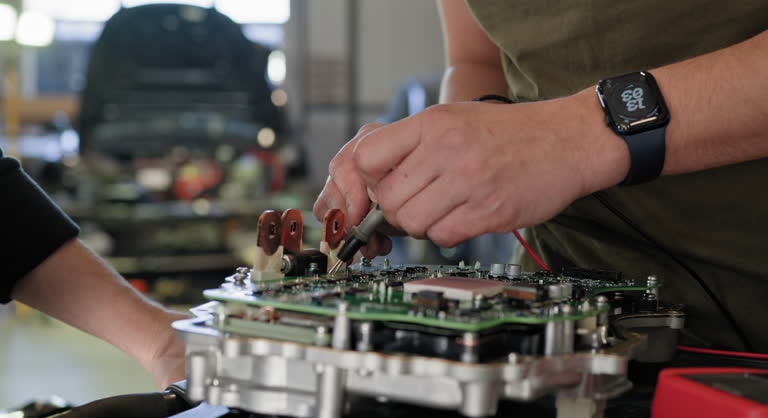

Role of Battery Management Systems (BMS)

In series and parallel batteries, Battery Management Systems are necessary. To ensure batteries are protected, they watch important numbers like voltage, current, temperature and state of charge. By means of the BMS, batteries are stopped from operating beyond safe ranges that cause overcharging, over-discharging, overheating and short circuits.

When electrical devices have cells connected in series, the BMS ensures the charge is evenly distributed so there’s no damage to the cells. BMS is responsible for balancing current and voltage so that every battery takes part in powering and charging the system.

Many modern BMS systems are equipped to connect to other external equipment or devices, as well as to communicate feedback. It makes it possible to check and adjust battery performance on the spot which keeps battery packs running safer and for longer.

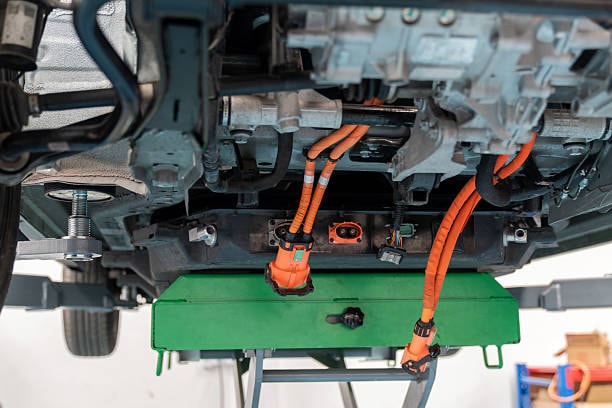

Safety Concerns in Series Circuits

Higher total voltage in series battery circuits means that safety must be given utmost consideration when designing them. If voltage levels are not controlled, these can cause electric shock, short circuits and thermal runaway. Errors in wiring or when the insulation wears down can cause conditions that put both equipment and people at risk.

A further safety problem happens if there is an imbalance of cells. When a faulty battery in the series is found, it can set off problems in other batteries which might overheat, catch fire or explode. Because of this risk, we need reliable protective systems and keep them regularly updated.

To prevent these risks, a strong Battery Management System and following proper design standards matter a lot. This prevents many problems by using fuses, circuit breakers and temperature sensors to improve safety.

Safety Concerns in Parallel Circuits

Since parallel battery circuits work at lower voltages than series circuits, the main safety issue is how to control the current. When many currents flow through parallel circuits, the circuits can get quite hot which may lead to fires if the system is not handled correctly.

Frequently, the current balance in parallel circuits becomes an important safety issue. Should one battery discharge faster or have a different voltage, it can pull more electricity from other cells, causing them to become warm and fail early. It is very important to align the specifications of your battery with a Battery Management System.

Off-target fusing or insufficient wiring may result in short circuits and the risk of a fire. Securing each connection, using the right cables and adding protective devices protects the battery during use.

Charging Considerations for Series Packs

Overcharging must be avoided when charging batteries linked in a series and each cell should be checked to make sure it gets the proper voltage battery type. Mounting a balance charger to the batteries is a usual way to detect each cell’s current as it charges and control it so each cell is treated the same.

When wiring batteries, if balancing is not done during charging a series pack, some batteries might be damaged because they become overcharged, while others don’t get enough charge and may be overstressed. An imbalance between cells can lead to thermal runaway, so it’s very important to balance them when charging your battery.

Frequently, a battery management system includes balancers which can talk to chargers to manage the operation, depending on how many batteries are connected . The systems keep cells evenly charged which helps keep the battery healthy and extends its overall life.

Charging Considerations for Parallel Packs

Charging a group of batteries connected in parallel takes same length less effort than charging batteries in series, because the cells have the same voltage. The charger provides current and both batteries safely collect and hold it, keeping the voltage at a safe level. Batteries should be charged until they have about the same charge level before they are joined.

If batteries with unequal power levels are wired together in parallel, the resulting flow of current can heat the circuit and put the devices at risk. Charging or balancing the batteries in advance helps keep the system safe and makes sure this problem does not happen.

These systems watch both the current used during charging and temperature to make sure the four battery does not get overcharged or becomes too warm. Advanced systems automatically manage charging, detect when something is wrong and update users on how things are working.

Effect of Temperature on Battery Performance

Battery packs, regardless of their arrangement, rely on temperature to achieve good results and live a long life. When temperatures rise, chemicals inside the battery can react faster, resulting in the battery wearing down, holding less charge and becoming a bigger fire hazard.

By contrast, if it gets too cold, the battery loses its capacity and the amount of current it can handle decreases which means devices might stop working without warning or become less efficient. Battery parts can become damaged by extreme hot or cold weather, shortening their overall life.

Keeping batteries within their proper operating range depends on efficient cooling, good insulation and temperature sensors in the BMS. It keeps batteries safe, improves battery life and helps your car stay better maintained for longer.

Importance of Battery Matching

When considering series and parallel circuits, battery matching by their voltage, capacity, internal resistance and state of charge is very important. With balanced current flowing and voltages distributed, performance is enhanced and no single cell suffers from major stress.

Improper four batteries in your car may cause issues such as overheating, greater wear on parts and possible dangerous malfunctions. Therefore, in series circuits, the overall pack performance can be restricted by a weak battery, but in parallel circuits, the current can travel unevenly through the individual batteries.

Manufacturers typically suggest that batteries used in vehicles should come from the same batch or be alike in specifications. Battery Management Systems watch over and handle any aspect of the pack that does not work identically to keep the pack both secure and efficient.

Current Flow in Series Circuits

The current in a series battery circuit is the same for every battery. Whatever the number of batteries tied together, all of them will receive the same amount of current in sequence. The design becomes simpler when current is the same, but the overall capacity cannot match that of the weakest battery.

When the current is unchanging, a small or broken battery can stop same length the complete flow of current throughout the device. As a result, the entire battery may work less efficiently and fail prematurely. That’s why all batteries connected in series should have similar capacities and be well maintained.

Even current flow is expected to share heat evenly, except that there can be subtle heat differences caused by the first battery’s inner resistance. Both checking and balancing are important for safe and effective work of series battery packs.

Current Flow in Parallel Circuits

All of the batteries are part of giving current to the load in a parallel circuit, allowing for the use of thinner wiring due to reduced voltage . Every battery adds current into the circuit according to its amount of stored energy and resistance. The current from thicker cables solar panels is split, so the overall current produced is higher than with single batteries.

Nevertheless, not every battery might cooperate equally, making some cells operate more than others. Excessive thermal heat can shorten battery life and make them fail.

When batteries are matched and managed correctly, all terminal of one batteries in a parallel configuration share current evenly, making the system safe and efficient. Because of this, parallel circuits are best for applications that require high current.

Advantages of Series Circuits

A big benefit of series circuits is that they can provide higher voltage to power higher-voltage devices. This setup means voltage remains users can obtain higher voltage than a single battery can give, so these batteries are useful for powering electric vehicles, tools and larger electronics.

A further advantage is that current flow is now simpler. Since every battery to the positive uses the same type of current, building charging and discharging systems is more straightforward. And, because all circuits are connected end-to-end, series circuits tend to be easier to wire.

Even so, batteries require careful handling to prevent them from becoming lopsided, especially in a parallel battery configuration . Even so, using series circuits is still common preference when you need high voltage and simple control of current.

Advantages of Parallel Circuits

At the same time, you have the option to deliver more electricity and power, without raising the voltage. That is why Li-ion batteries are suitable for devices with high voltage requirements, including flashlights, smartphones and storage systems.

Another good thing is that data is replicated. In a parallel combo, losing one battery won’t usually affect the other batteries and the device will keep running. Verifiable details are what must be provided for any crucial application which is what this provides.

Furthermore, joining batteries in parallel spreads the load among the parallel connected batteries, making it less hard for each of them to function properly. Managing balancing allows the batteries to run longer without stressing them out.

Disadvantages of Series Circuits

However, there are a few flaws you should keep in mind regarding series circuits. As soon as a battery stops being usable in the pack, the whole battery pack fails. If a cell is lower on performance or harmed, it reduces the amount of current it can send which reduces the pack’s efficiency and storage space.

Batteries in a hybrid vehicle may also end up out of balance. Because several batteries are used more than others, the group might not be the same voltage and capacity. Not being careful can result in major hazards such as an overheated battery or a fire.

Specifically, since the voltage of series packs is high, systems must have additional insulation and safety features to protect both people and the equipment. Because series circuits have these issues, we need to approach their design and maintenance with added support.

Disadvantages of Parallel Circuits

Parallel circuits too can cause issues. Making sure all several batteries are equal in voltage can add a lot of complexity to connected circuits. Batteries with different charge levels that are attached might give a lot of current which could cause cell damage.

Having uneven resistance in batteries may lead them to offer different currents, causing more voltage drop, which can cause parts to wear differently. Untreated imbalance in phones can decrease the life of the battery and weaken reliability.

In addition, building parallel circuits takes more wiring and connectors which can make things more complex and pose extra chances for errors. Proper action on these points is necessary for a boat to function safely and for many years.

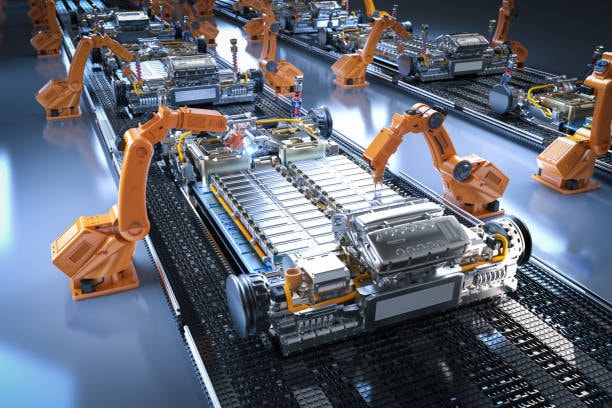

Applications of Series Battery Circuits

Many applications that need high voltage are powered by series battery circuits. Electric vehicles (EVs) need lots of power to move buildings up and down and series-connected lithium-ion cells are used to achieve this in EVs, often complemented by a series parallel connection for optimal performance .

Series connections in portable electronics such as laptops and power tools, make it possible to provide the right voltage, without making the devices too big. Doing this well relies on how well the device can handle easy flow of current and deliver higher voltages.

Renewable energy like solar energy is often constructed with series batteries which keep electricity at a higher voltage, meaning it is simpler to join these systems to inverters and the grid.

Applications of Parallel Battery Circuits

Parallel circuits do well in roles that require steady power and a long lasting battery. Smartphones and tablets last longer between charges thanks to their parallel battery packs which do not need to increase the voltage to achieve this effect.

Regularly, homes and businesses use connected systems for storing energy, so that they can meet their energy spikes safely. With this approach, you can easily add modules and the system will still be reliable.

With both backup power supplies and UPS, parallel circuits make the system flexible and dependable, so it can keep working if any cell stops functioning.

Combining Series and Parallel Circuits

Generally, the right voltage and capacity are achieved when battery packs are connected both in series and parallel. For example, linking batteries in series and then running them in parallel allows you to enjoy benefits from both methods.

The use of both batteries and supercapacitors forces complex systems to monitor each cell and each group to keep them operating safely and efficiently. Both voltage and current in these systems need to be balanced to avoid harm and improve their performance.

These power combinations are found in electric vehicles and big energy storage systems, as accurate power requirements there require versatile batteries that can be adjusted.

Troubleshooting Series Circuits

Series battery circuits can be checked by finding cells with unusual voltage, ability to hold charge or resistance. As every cell is the same, a failing one can weaken the performance of the whole pack, so being vigilant about early problems is necessary.

By testing single cells together and also checking the temperature, it’s easier to find batteries that are damaged or not functioning properly. Sometimes, dropping voltage, overheating or swelling indicate that you need to replace or rebalance the battery.

Maintaining your battery and managing it well through monitoring tools keep you informed, allow you to avoid major failures, reduce waiting periods for repairs and avoid long downtimes.

Troubleshooting Parallel Circuits

When fixing parallel battery circuits, you should make sure that cells have the same voltage and have a sharing current. Since in parallel, the batteries share what is draw, a mismatch may cause some to work harder than others, resulting in wear and might cause them to fail. Early finding of these issues can help maintain good functioning of the system and avoid damage.

Often, voltage differences between batteries result in excess current that can heat up the batteries and harm their cells, for example if you connect batteries with unequal charge leve . By measuring individual cell voltages often, you may easily find such problems. It’s a good idea to monitor different temperature readings, because these can indicate batteries that are struggling or not working properly.

Battery management systems (BMS) help engineers fix problems with parallel circuits. They constantly check voltage, current and temperature and are equipped to either inform of problems or remove dangerous cells, making charging more reliable and longer lasting.

Role of Battery Management Systems (BMS)

Battery Management Systems (BMS) are important because they ensure both safety and high performance in series and parallel battery circuits. Battery management systems watch each cell’s voltage, temperature and current to prevent them from operating outside safe range. It is important because unchecked cells could cause your batteries to overheat, overload or run out entirely, all of which are bad for your vehicle.

In this kind of circuit, BMS maintains proper voltage in every cell, avoiding both overvoltage and under voltage cases. Balance Managers Simultaneous (BMS) monitors and adjusts current so that the workload does not differ greatly across individual circuits. It makes sure that if the wiring shorts, the circuits are interrupted and heat cuts off, all of which play a big role in user safety.

The latest BMS units can talk to external gadgets, so users can observe their battery’s functionality and status remotely. With such data, maintenance can be scheduled, potential issues can be anticipated and power from the battery can be managed to support a battery’s performance and lasting abilities.

Impact of Temperature on Battery Circuits

How batteries function, how safe they are and how long they last depend greatly on temperature in series and parallel layouts. Elevated levels of heat accelerate chemical activities inside the battery, enhancing wear and raising the threat of batteries overheating dangerously.

With low temperatures, batteries can’t store as much charge, electricity moves slowly through them and they lose power at a quicker rate. Controlling the gaps in supply becomes very important in uses where outside conditions are extreme and could harm the batteries.

Most battery management systems use temperature sensors to check and control charging and discharging in a safe temperature zone. Using cooling systems or insulation is necessary to keep systems safe and protect their regular operations.

Charging Series Battery Circuits

The arrangement of batteries together in a series means special attention to voltage and current must be taken to avoid charging the cells beyond what is safe. Total voltage is made by adding each battery’s voltage, so chargers must make sure every cell receives equal charge.

If cells are not well balanced, a few may run over, while others don’t get a full charge, resulting in losing capacity and possibly causing safety issues. Smarter chargers created for series pack systems have balancing circuits that help distribute the charge between all the cells.

Series packs take longer to charge up because every single cell has to charge to a safe level. The use of quality and well-managed series battery circuits can result in both better performance and more lasting batteries.

Charging Parallel Battery Circuits

When you charge batteries in parallel, it’s simpler since all the cells share the same voltage. A charger supplies the same voltage as one cell and adding more batteries to the circuit increases capacity for more extended use.

Still, all batteries should be charged about the same amount before you join them in parallel. Devices in charging systems may prevent larger currents from getting to weaker cells.

Parallel charging has redundancy so that if a single battery fails or comes loose, the others still supply charge and keep the device running. Many portable and stationary items benefit from this level of resilience.

Safety Risks in Series Circuits

If series battery circuits are not controlled well, they can be unsafe. With more cells included, the packaging must be thought out well, as both risk of electric shock and possible insulation failure rise.

If you overcharge or over-discharge a single cell paired in series, there is a chance it may overheat or swell which can cause thermal runaway and fire. Careful adjustment of each cell’s voltage reduces the risk of hazards.

Any cell in the pack that suffers damage or normal age-related changes may create an internal short circuit which may result in failure of everything in the pack. For safe use, devices must have strong protection using circuits, fuses and battery control.

Safety Risks in Parallel Circuits

Even though parallel battery arrangements involve a lower voltage, they can still pose big safety risks. Unbalanced charges in batteries may result in brief surges of electricity which may harm the batteries or spark a fire.

A minor fault in a single battery may cause it to give off much more current, raising the risk of overheating for the other batteries. The equipment needs isolating components and proper fusing so that faults are identified swiftly.

Regular maintenance, checking the state of the batteries and looking at the battery voltage levels, reduce risk. Thanks to battery management systems, we can find and address issues with our batteries.

Battery Lifespan in Series Circuits

The lifespan of the battery in series goes according to the weakest battery. Since each cell delivers the same current, cells with less capacity or higher resistance deteriorate first and damage the rest of the pack.

When cycles aren’t evenly balanced, the battery misuses its capacity and experiences more stress which reduces service life. If you balance and condition your battery often, it may last longer.

Using matched batteries in a series assembly and following high-quality management systems helps each cell age the same and perform consistently, making the series battery last longer.

Battery Lifespan in Parallel Circuits

Because current is shared in parallel circuits, less pressure is placed on each battery cell which adds to their total service time. Under regular use, the batteries each receive current and none is made to handle more than it can handle.

If the batteries are not maintained well or if their cells clash, some batteries might fail earlier due to the extra work they need to do. Checking the balances and stand conditions often help you get greater use and longer-lasting skates.

Because parallel systems are connected, faulty batteries can be removed without this affecting the rest of the batteries or basic system functions.

Environmental Considerations for Battery Circuits

Environmental risks associated with battery circuits should be considered during design and their application. Both types of circuits should use materials that do not harm the environment and be properly disposed of to keep harm to the environment low.

Taking care of your batteries means they last longer with less energy used, saving you money and the environment. Upcycling lithium-ion and similar batteries encourages the recovery of metals as well as the safe disposal of waste.

If products are made to be easy to disassemble and use again, this helps the environment. Environmental consideration should be as important as good performance and safety for both users and manufacturers.

Cost Implications of Series vs. Parallel Circuits

The choice between series and parallel battery circuits depends greatly on cost. Because their parts are linked, series circuits often ask for batteries with matching voltage and capacity and also for more balanced and protected circuitry. When you use it, the expense of equipment goes up but the wiring may be simpler and the system can avoid current losses.

Adding extra batteries in parallel allows the capacity to grow with several batteries out affecting voltage and helps save money. Nonetheless such systems need strong surge protection and accurate battery matching which might increase management costs.

Also, maintaining and replacing different systems can have different costs. By using a parallel setup, a damaged battery only affects one unit, reducing long-run expenses since the whole pack doesn’t have to be changed.

Applications Best Suited for Series Circuits

Circuits that use series battery connections are often preferable where a high voltage is required. Often, electric vehicles are built with series connections to get the voltage needed to run the motors well. When you increase the voltage, you can lower the current and, as a result, both losses and the thickness of wiring.

Portable electronics and power tools need the small-scale advantages of a compact voltage source. Different series configurations let devices reach appropriate voltage levels without the use of unique transformers or converters.

Despite the advantages, balancing and overseeing a series circuit is important, so it is usually found in places where these efforts are justified by requirements for high voltage.

Applications Best Suited for Parallel Circuits

When you need to increase how much your system can carry or how long it can run, a series parallel connection configuration is preferred. To increase how long backup power systems, solar energy storage and portable power banks work, they are usually connected in parallel.

The fact that voltage does not change in parallel setups means it’s suitable for devices that can draw variable current but require a consistent supply of voltage. Since the load is divided among batteries, failure in one won’t shut off the whole system right away.

Plus, adding or removing extra storage is simple in parallel circuits, so users can create flexible and scalable energy systems that meet their energy needs.

Voltage Regulation in Series Circuits

Due to the total voltage contributed by all the cells, it’s challenging to control voltage in series battery circuits. Controlling each cell equally is necessary so that the battery doesn’t output too much voltage and harm the cells.

These circuit parts regularly maintain stability of the cells by adjusting charging and discharging depending on the voltage. This feature is necessary for the safety of electronics that use a series of batteries.

Integrating advanced regulation with external controllers allows the system to respond quickly to changes in load, making applications more efficient and extending battery life.

Voltage Regulation in Parallel Circuits

All the batteries have the same voltage in parallel circuits, so voltage regulation isn’t as complicated. The main problem is making sure the charge in each battery remains close, so the current is divided evenly.

Voltage regulators keep the same voltage in the system while redirecting current from batteries that are full to those that are almost empty. So, each battery cell won’t be stressed by overcharging or deep discharging.

Regular voltage in parallel circuits helps machines work well and avoids damage, so it is essential to upkeep stable voltage for many years.

Importance of Matching Batteries in Series Circuits

The reason to use matched batteries in series is so they all maintain the same amount of voltage, capacity and resistance. Having difference among the batteries may cause some of them to be fully charged while others are nearly empty.

Destroyed batteries lose their effectiveness fast, cause the whole pack to work less efficiently and can make the batteries overheat. Often, battery manufacturers suggest buying batteries that are the same and from the same lot for series packs.

When batteries are carefully matched, their efficiency goes up, battery life lasts longer and there’s no need to balance or adjust them as often.

Importance of Matching Batteries in Parallel Circuits

When batteries in a parallel circuit are exactly matched by voltage and capacity, their workload is shared and nobody is loaded more than necessary. If batteries are not uniform, it can cause one to wear out quicker and lose performance.

Matching components accurately reduces the chance of reverse currents that can damaged the cells or cause overheating. Checking state of charge and how healthy the batteries are should come first, prior to connecting them in parallel.

Working batteries of the same type operate smoothly, last longer and perform safely which is important for backup or green energy applications.

Influence of Internal Resistance in Series Circuits

Each battery cell’s behavior inside resists change to the overall series circuit. Resistance in one cell can result in voltage drops and heating which lowers the whole battery pack’s efficiency and amount of power delivered.

If cells have different levels of internal resistance, the current will not be even during charging and discharging which speeds up wear and reduces the battery’s capacity. For this reason, balancing circuits is needed to keep performance consistent.

Improved energy delivery and longer battery life in a series arrangement happen when internal resistance is reduced by using strong cells and good care.

Influence of Internal Resistance in Parallel Circuits

In such circuits, resistance inside the batteries changes the way current is distributed among them. Large current passages from a less resistant cell can overload the part and cause it to break down before it is supposed to.

Fewer weak cells in a high resistance battery can cause troubles. Because of this, lifestyle adjustments are important, along with taking care of your systems.

In parallel battery systems, managing how people respond internally ensures the equipment runs efficiently and has a longer lifespan.

Testing and Maintenance Practices for Battery Circuits

Safety, efficiency and long service life of battery circuits depend on regular testing and maintenance. Parts of the testing procedure are checking voltage, resistance within a battery, its temperature and its appearance.

Preventing problems means to clean the terminals, secure all connections and change any bad battery cells at once. In series packs, making sure the voltage is even between cells is important to keep them safe and for parallel packs, matching the amount they are charged helps prevent increases in current.

Frequent inspections plus checking battery health using analyzers or BMS data allows us to detect problems early and reduce the risk of downtime on every application.

Role of Battery Management Systems (BMS) in Series Circuits

Series battery circuits depend on BMS for proper and secure operation. Since the total voltage in a series circuit comes from each battery, the slightest difference between cells can make one or more unbalanced. Three main things are checked by the BMS at all times in each cell: voltage, temperature and current to avoid overcharging, deep discharging and overheating.

By regulating charging, a good BMS can fix cell differences or turn off cells that display abnormalities. Keeping an eye on battery voltage helps batteries last longer and prevents accidents, as needed for applications including electric cars and big energy storage systems. A series battery pack without a BMS can experience uneven wear out, reduced capacity and even dangers. That’s why adding an effective BMS is absolutely crucial when dealing with series configurations.

Role of Battery Management Systems (BMS) in Parallel Circuits

The BMS serves a different function in parallel battery circuits that is also very important. The BMS is needed because all batteries have the same voltage, but each has its own capacity or state of health, so the BMS keeps track of current usage and battery level for each one.

Excess current from stronger batteries to weaker ones is prevented by the system to protect both batteries from being damaged or overheating. Noticing failing batteries is also important so they can be isolated, without turning everything off. Controlling these aspects, the BMS helps to keep charging and discharging balanced for all cells connected , thus increasing the reliability and how long these circuits last, mainly in applications running on high capacity and for a long time.

Safety Concerns in Series Battery Circuits

The main risks in series battery circuits are about voltage building up and cells having an imbalance. Because voltages add together, the chances of an electric shock or short circuit become greater than with either single cells or parallel setups.

When cells in series become imbalanced, their batteries can become overcharged or deeply discharged which might result in overheating, swelling or even a dangerous fire. Adding good insulation, matching batteries well and using safety protections will significantly reduce these risks.

Additionally, heat management is necessary since an overheated cell in the pack can trigger problems across the whole battery, so having monitoring systems helps catch these problems early and keep everything safe.

Safety Concerns in Parallel Battery Circuits

Main risks in parallel circuits have to do with current overloads and areas where the load is not balanced. When batteries are connected in series, those with higher charge pass current to those with lower and sometimes this creates too much current for a few of the cells.

When this imbalance happens, the device may overheat, be damaged inside or face fire hazards due to lack of protection. Three key safety features are proper fusing, matching the battery to the charger and a strong BMS.

Precise monitoring and secure data links are both needed to avoid dangers, mainly in large sets of batteries for emergency power or renewable energy storage.

Charging Characteristics in Series Circuits

You should make sure the voltage in the series battery pack is regulated and that each device is charged the same to avoid any alarming issues during charging. Since charging all the cells at once, chargers should deliver the right voltage without damaging any weak ones.

An extra charge from fully charged cells gets drained by a balancing circuit to sustain even voltage in the pack. Doing this helps keep the battery healthy and strong.

The slowest cell can hold back the charging of the rest, so all cells in series should be maintained in the same health and capacity to ensure top charging efficiency.

Charging Characteristics in Parallel Circuits

Because parallel circuits provide steady voltage, the charging process is somewhat easier than with series-connected batteries. Chargers keep the charging voltage constant but allow current to divide depending on how each battery is charged.

Nonetheless, if the batteries in your phone are not all charged the same amount, the current could surge which may result in cell damage or a quicker life span for the phone’s battery. That’s why you should use chargers or BMS systems that protect the cells from damage and even out energy use.

When the system is charging, it’s important to check every so often so the batteries don’t overcharge and maximize the pack’s performance.

Discharging Behavior in Series Circuits

All the cells in a series battery circuit receive the same current, but the total voltage is the sum of each cell’s voltage. A constant current flows through the body’s electrical system only when cells are healthy, to prevent mistakes and early breakdowns.

Sometimes, if a cell is less powerful or has internal resistance, the whole pack’s performance can suffer and the weaker cell might end up discharging completely, harming it permanently.

It is very important to check and adjust the amounts being discharged to keep cells safe and preserve the battery pack’s quality and effectiveness in series.

Discharging Behavior in Parallel Circuits

Batteries in parallel keep the same voltage, but their currents join together. Each battery is included in the current supply depending on its charge and the energy it can hold.

A battery that is damaged or operating at low power might cause the vehicle to use too much current or empty too quickly, leaving you with poorer performance. Batteries won’t perform well if not managed for proper monitoring.

Longevity and function of parallel battery packs are increased by managing the battery and conducting routine maintenance.

Impact of Temperature on Series Battery Circuits

Series battery circuits depend greatly on temperature for their performance and protection against dangers. If the body temperature is above normal, chemical reactions inside the cells may go too fast and may eventually lead to a chain reaction that causes more heat.

Series packs are very sensitive to uneven heat, since a cell becomes overheated when its neighbor is hot, risking accidents or damage.

Proper thermal management uses both fans or heat sinks and temperature sensors under the watch of the BMS to safeguard the machine’s performance.

Impact of Temperature on Parallel Battery Circuits

Temperature mismatches in parallel circuits may disturb the way current flows and jeopardize the health of your batteries. Giving cells more heat can hasten their aging and throw off the overall balance within the battery.

Cooler batteries commonly receive more current when paired with hotter batteries because the whole current is flowing through them which can cause stress in the healthy cells.

Being careful to standardize every battery’s temperature and ventilation helps avoid imbalances and extends the life of parallel battery packs.

Importance of Cell Matching in Series Circuits

Because series battery circuits require energy from the same cells, choosing cells with similar properties is essential to avoid problems. When cells do not match, the weakest one in the series will determine both the battery’s storage and its longevity. Over usage of particular batteries may eventually result in overcharging or deep discharging which damages them and cannot be fixed.

To avoid these problems, those making batteries typically pair identical or nearly identical cells together before using them. With equal charging and discharging, all cells function at their highest level and last longer. Good cell pairing also limits the risks of hazards that come from putting too much pressure on a specific cell.

Simply put, matching cells makes series battery packs stronger, more dependable and safer. The main benefit of having several cells in series is defeated if the battery ages early or if its capacity declines.

Importance of Cell Matching in Parallel Circuits

Just like with series, matching batteries is as crucial in parallel circuits. Because each parallel battery is held at the same voltage, but may supply various amounts of charge, current may travel unevenly when the cells are not matched. As a result, some batteries can become too hot and last for less time.

When cells are joined, batteries with the same voltage, capacity and internal resistance are used to allow even current sharing. Because of this, weak batteries are used less which helps keep the rest of the pack healthy and aged similarly. Some batteries can fail too fast if not matched properly which can damage the battery pack as a whole.

Cell matching in parallel helps stabilize the system, improve safety and stretch the battery’s life, a necessity for use in important and demanding situations.

Balancing Techniques for Series Battery Packs

Keeping the voltage the same in all batteries is done through balancing techniques in series packs. By balancing the cell capacity, we avoid charging them too high or running them low which can result in problems or damage to each battery.

People use both passive and active balancing as main ways to balance. As a simple method, passive balancing funnels extra energy from higher voltage cells into resistors to produce heat which is not very efficient. With active balancing, high-voltage cells give charge to low-voltage cells to make the pack work better, but the arrangement is more complex.

Applying the right balancing method keeps the batteries working as expected and lasts longer, particularly in electric vehicles and big energy storage systems.

Balancing Techniques for Parallel Battery Packs

When using parallel battery packs, the main concern is making sure the current does not get too high, because the cells are all at the same voltage level. To prevent any of the batteries from becoming overly stressed, current must be spread out evenly.

Often, parallel systems use sensors and controllers to steer or manage the current running between various components. There are BMS setups that balance the battery cells without extra equipment, watching for and handling imbalances over time.

When parallel circuits are balanced well, batteries are more dependable, heating and failure risks decline and the entire system operates more smoothly.

How Internal Resistance Affects Series Circuits

How efficiently a battery cell delivers power depends in part on how resistant it is internally. While circuits work one after another, the voltage and current values can be affected by the collective resistance of all batteries.

When a cell’s internal resistance is high, voltage drops, heating occurs and the battery does not charge evenly which may decrease performance and create safety issues. It can make the battery pack heat up differently which puts stress on some battery cells.

Series battery packs work well and for a long time when little internal resistance is generated by steadily choosing, pairing and maintaining the cells that keep them lasting and efficient.

How Internal Resistance Affects Parallel Circuits

The resistance seen inside the battery decreases when the load is shared by several cells. In most cases, this leads to an increase in power and better efficiency than single cells can manage.

But if a battery shows much higher resistance inside, it will slow down the current to others and cause them to run out faster, leading to early wear.

Ensuring balance in current sharing, safety and optimum performance of parallel battery systems requires controlling the differences among internal resistances.

Impact of Load Variations on Series Circuits

How a series battery is loaded can change how it performs a lot. Because every cell in a battery is connected the same way, any sudden change in load will cause all cells to react at the same time.

When the load is excessive, the inferior cells face too high a load which may result in them overheating or being damaged. Similarly, much lighter loads can be wasteful with energy and result in batteries draining more slowly.

Building series circuits that work well with changes in load involves using suitable cells, adding safety circuits and using smart fatr battery management.

Impact of Load Variations on Parallel Circuits

The variations in load will be handled differently in a parallel circuit because the current distributes among every battery. If the load is increased, the capacity and charge of each battery limit the current being supplied.

When batteries share their load unevenly, the overuse of some can cause them to overheat which speeds up their aging. Left unused, some batteries can keep their charge for a long while which can lead to a balance problem in the system.

Appropriate cell and battery management ensures that parallel battery packs continue to function well and efficiently under lots of conflicting loads.

Summary

This part examined essential elements that determine the running time and condition of batteries arranged in series and parallel configurations. Proper voltage, capacity and resistance at each cell were considered important for both types of batteries to protect the batteries against factory-to-field operational shifts that decrease the life of the batteries or create safety concerns. Both active and passive techniques are essential to protecting batteries from problems that lead to overcharging or over-discharging.

How resistance inside battery cells affects both energy efficiency and heat varied for series and parallel circuits. Series circuits increase their total resistance by the same amount as each component, but parallel circuits can lower total resistance and it’s possible for currents to share unevenly if some components are clear discrepancies. Wherever circuits are changed, altering the loading, design and management must ensure that the cells are not put under too much stress. Furthermore, as series packs age, the voltage gets out of balance which leads to poor performance. But parallel packs will show uneven current loading that can damage battery components if not controlled.

You should regularly inspect your batteries, look after each cell individually and make use of high technology to control these processes. As a result, the use of these measures guarantees the security, dependability and long-term usefulness of battery packs in various situations.

Conclusion

Designing effective and secure energy storage systems requires good knowledge of series and parallel battery circuits. Taking care of cell matching, balancing and controlling internal resistance and the load is necessary for getting the best from the battery. If you look after signs of aging and rely on advanced battery management systems, your batteries will serve you safely for longer.

With people needing more energy and batteries getting better, knowing these things will help users, engineers and manufacturers perfect battery packs for portable gadgets, electric vehicles and grid storage. Making sure we handle series and parallel battery settings well leads to stronger, more stable and better-performing power systems suited for current technology needs.