Introduction

Modern technologies work through lithium-ion batteries including mobile devices, laptops, electric vehicles along with renewable energy storage systems. Users usually ignore the important voltage threshold known as cutoff voltage which operates underneath the dependable battery system. The set threshold controls the charging and discharging actions of batteries and directly affects their functions and operational time. Knowledge of cutoff voltage stands vital for extending battery capacity as well as safeguarding users from dangerous situations through effective discharge protection . This paper explains the scientific foundation of lithium-ion battery cutoff voltage together with its key role across different uses and proper battery governance systems.

What Is Battery Cutoff Voltage?

The battery management system (BMS) stops charging or discharging processes when voltage reaches predetermined thresholds called cutoff voltage. The established cutoff points act as safeguards to prevent battery operations beyond a secure voltage zone, providing over discharge protection . There are two main cutoff voltages used for lithium-ion batteries that need protection.

- Lower cutoff voltage (discharge cutoff): A battery should stop discharging at the commanded lower cutoff voltage value to avoid over-discharging the cells.

- Upper cutoff voltage (charge cutoff): Charging should stop when it reaches an upper voltage threshold (charge cutoff) because this prevents overcharging damages to the battery.

Scientists set these values properly after conducting thorough chemical testing of individual lithium-ion battery designs.

The Chemistry Behind Cutoff Voltage

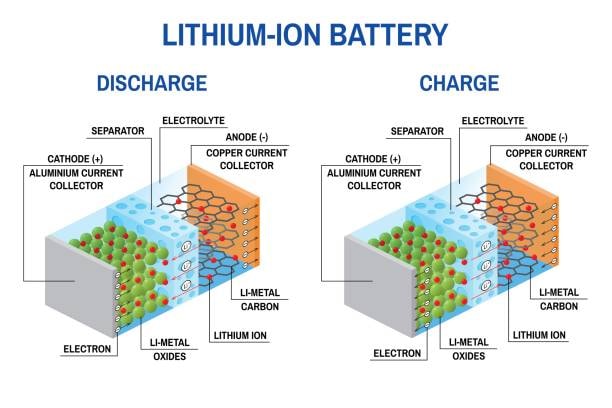

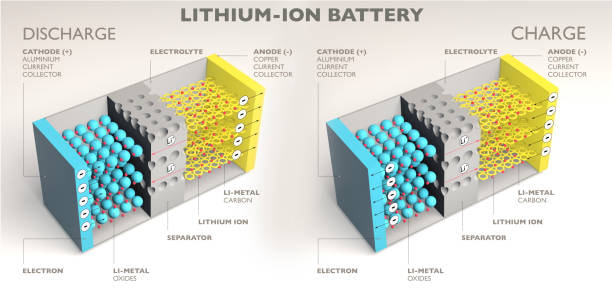

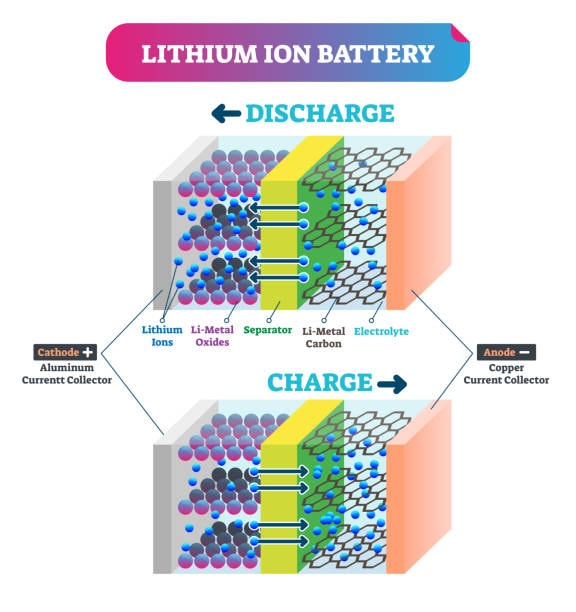

The understanding of cutoff voltage requires knowledge about internal battery reactions while operating. The electrochemical reaction of lithium-ion batteries enables the lithium ion exchange between anode and cathode electrodes along an electrolytic pathway, influencing overall battery power .

The movement of lithium ion particles proceeds from the anode material graphite towards different lithium-metal compounds that serve as cathodes throughout the discharge process. Electrical transmission occurring through an external circuit follows the electron release from the battery operation. An external voltage source executes lithium ion transport back into the anode when the battery charging process occurs.

The voltage reading directly represents the present energy condition of this whole system. At the point when a battery reaches its minimum voltage operating threshold, most lithium ions have relocated to the cathode. Further battery discharge from this low voltage threshold value enables unsafe chemical processes which could result in structural damage of capacity and safety issues.

When lithium-ion cell voltage exceeds its upper edge the anode material reaches lithium-ion saturation point. Continued charging after the maximum voltage limits will result in lithium plating of metallic lithium deposits on the anode which presents serious safety hazards through internal short circuits.

Typical Cutoff Voltage Values

Lithium-ion chemistry cells operate with specific optimal voltage intervals that differ between types. Table 1 shows the usual voltage limits for standard lithium-ion battery models.

Lithium Cobalt Oxide (LiCoO₂/LCO)

- Lower cutoff: 3.0V per cell

- Upper cutoff: 4.2V per cell

- Nominal voltage: 3.7V per cell

Lithium Iron Phosphate (LiFePO₄/LFP)

- Lower cutoff: 2.5-2.8V per cell

- Upper cutoff: 3.6-3.65V per cell

- Nominal voltage: 3.2-3.3V per cell

Lithium Nickel Manganese Cobalt Oxide (LiNiMnCoO₂/NMC)

- Lower cutoff: 2.5-3.0V per cell

- Upper cutoff: 4.2V per cell

- Nominal voltage: 3.6-3.7V per cell

Lithium Nickel Cobalt Aluminum Oxide (LiNiCoAlO₂/NCA)

- Lower cutoff: 3.0V per cell

- Upper cutoff: 4.2V per cell

- Nominal voltage: 3.6V per cell

These values represent general guidelines. Various battery makers use different voltage cutoff limits based on how their units are built for specific customer needs.

The Consequences of Exceeding Cutoff Voltage Limits

Exceeding Lower Cutoff Voltage (Over-discharge)

Multiple negative impacts emerge when cells reach below their specified minimum operating voltage.

- Copper dissolution: The electrolyte dissolves the copper material from the anode current collector when electric potentials reach sub-optimal levels. Internal short circuits can result when copper that was removed by recharging redeposits as dendrites on battery components.

- SEI layer breakdown: The Solid Electrolyte Interphase (SEI) layer protecting the anode cells from damage breaks down after over-discharge thus causing higher internal resistance and capacity loss.

- Structural degradation: The materials which compose the electrodes will damage structurally when exposed to operations which exceed their operational stability limits.

- Voltage depression: The continuous pattern of over-discharging batteries forces the discharge voltage to move downward and then bothers the usable capacity decreases.

- BMS lockout: The integrated BMS safety feature disables over-discharged batteries which cannot operate without specific recovery measures.

Exceeding Upper Cutoff Voltage (Overcharging)

Charging the battery above its upper cutoff voltage leads to dangerous outcomes that surpass those of overcharging, especially when high cut off voltage is involved .

- Lithium plating: The formation of metallic lithium dendrites on anode surfaces occurs when lithium ions plate instead of intercalating within the structure while penetrating through separators to cause short circuits..

- Thermal runaway: The process of exothermic reactions begins when overcharging occurs which produces thermal runaway that intensifies additional chemical reactions through a destructive positive feedback mechanism.

- Gas generation: The decomposition of electrolytes generates gases that create internal pressure inside sealed cells which results in swelling or rupture of the cells.

- Accelerated aging: The process of operating a battery beyond its upper voltage tolerance leads to quick deterioration of electrode materials together with electrolyte components thus damaging the cycle performance.

- Cathode degradation: The release of oxygen from cathode materials becomes possible when cells operate at high voltages which leads to additional electrolyte reactions.

Proper cutoff voltage management and parameter settings stand essential for battery protection, safety as well as longevity because of these security risks.

Cutoff Voltage in Consumer Electronics

Consumer electronics rely on battery management integrated circuits and protection circuits to enforce cutoff voltages between performance requirements and safety standards along with device longevity. Company makers choose different options within accepted safe parameters.

Smartphones and Laptops

Smart electronics use lithium polymer together with LCO/NMC batteries which work hand in hand with complex battery management platforms. Device manufacturers choose a 3.2 to 3.4V lower cutoff limit for their batteries although the chemical restrictions indicate 3.0V. This helps batteries last longer. The standard maximum voltage for battery charging is 4.2V yet select high-end devices automatically restrict their battery charging to 4.0-4.1V to lower the stress on the battery.

The optimized charging feature of manufacturers allows batteries to determine cutoff voltages according to user habits. The system keeps the battery at 4.0V cell voltage or 80% charge until the time period before the user usually unplugs the device to decrease charging to high states.

Power Banks and Portable Chargers

Power banks use discharge cutoffs between 3.0V and 3.2V to obtain the most possible power output for connected devices. Quality power banks use various protection systems along with safety boundaries to block both overcharge and discharge cut off voltage incidents.

Cutoff Voltage in Electric Vehicles

The management requirements for electric vehicle batteries become highly advanced because of safety protocols and significant stored energy levels. Ev battery packs consist of many individual cells which require precise voltage management because they total hundreds to thousands of cells.

Range vs. Longevity Tradeoffs

The range capabilities of EVs exist in careful equilibrium with longevity estimates determined by manufacturers. EV technology employs NMC or NCA batteries theoretically able to discharge to 3.0V per cell but actual user-available reserves stop at 3.2-3.3V per cell (10-20% as indicated on displays). During regular daily charging EVs restrict voltage to 4.1-4.15V per cell which stands at about 90-95% of the displayed state of charge instead of charging up to the maximum capacity of 4.2V.

Battery Preservation Modes

Electro-Vehicles come equipped with customized charging modes which control battery cell voltage thresholds for life extension purposes:

- The standard charging feature restricts the upper cut-off point to reach only 90% of maximum capacity.

- The range mode allows users to reach chemical limitations (upper cutoff) periodically when conducting extended trips.

- By setting the storage target at 50-60% (3.7-3.8V per cell) the device minimizes battery aging during storage duration.

Temperature Compensation

Temperature conditions lead EVs to modify their cut-off voltage levels automatically. Lithium plating formation can be prevented during charging by elevating cutoff voltages in cold temperature settings, thereby reducing self discharge . The upper voltage limits receive reduction in hot temperatures to suppress degradation reactions which increase speed when temperatures climb higher.

Industrial and Energy Storage Applications

Powerful energy storage systems choose prolonged life span and operational safety above energy storage capacity thereby requiring limited cut-off voltage ranges.

Grid Storage Systems

Grid-scale lithium-ion facilities deploy LFP technology because it offers both thermal stability along with extended cycling ability. Lithium-ion systems that store energy normally function in smaller voltage bands compared to their theoretical capabilities.

- The lower terminal voltage range operates between 2.8V-3.0V per cell as the minimum should be set at 2.5V.

- The cell accepts voltages between 3.45V and 3.55V for upper cutoff limitations though the absolute permissible voltage reaches 3.65V.

Overly cautious voltage management techniques enable these installations to nearly half their energy capacity while prolonging operation by two to three times thus making business cases more compelling.

Uninterruptible Power Supplies (UPS)

The reliable standby capacity of UPS systems must operate effectively for several years before delivering complete power instantaneously. Lithium NMC cells in such applications operate within specific voltage ranges to enhance durability by maintaining 3.2-3.3V for lower cutoff and 4.0-4.1V for upper cutoff.

Measuring and Monitoring Cutoff Voltage

Battery Management Systems (BMS)

The implementation of any lithium-ion battery system depends on using a BMS for voltage control and monitoring functions. A continuous BMS monitoring system measures individual cell group or cell voltages through the following functions:

- The system cuts off the discharge operation when one cell touches its designated lower threshold value.

- A battery charging operation must stop when the upper cutoff is detected in any single cell.

- A system should keep battery cells balanced during charging operations for uniform voltage distribution.

- The system must adjust lower and upper voltage limits according to changing temperature and battery age.

- Log voltage data for diagnostic purposes

Complex systems use predictive algorithms within the BMS to estimate cutoff voltage levels so the battery transitions become smoother.

State of Charge Estimation

Temperature coupled with discharge rate along with aging capacity influence the non-linear SoC-to-voltage relationship of lithium-ion batteries. The middle section of standard lithium-ion battery discharge exhibits consistently flat voltage output which renders voltage measurement insufficient for SoC measurement.

Up-to-date BMS systems deploy various techniques for SoC estimation.

- Voltage measurement

- Current integration (coulomb counting)

- Internal resistance measurement

- Temperature compensation

- Aging compensation

The SoC calculation allows users to make correct voltage cutoff adjustments that benefit battery longevity.

Extending Battery Life Through Cutoff Voltage Management

Users seeking to extend battery life with system developers will benefit from adjusting voltage cutoff limits.

Partial Charging Strategies

Scientific evidence demonstrates that cycles become longer when lithium-ion batteries remain within a charge level between 20-80% SoC range. This approach works by:

- The lower voltage threshold should be set at 3.4-3.5V per cell equivalent to 20% state of charge.

- To reach approximately 80% SoC the upper cutoff voltage should be set at 4.0-4.1V per cell.

The implementation of this procedure results in 40% lower available capacity but extends the cycle life between 200% to 300% or beyond. The combination of these tactics allows for maximum operational efficiency as long as continuous power usage is not necessary.

Temperature-Adjusted Cutoff Limits

The temperature level determines which cutoff voltages will lead to optimal results. As a general rule:

- The cutoff voltage needs adjustment to 0.1-0.2V per cell when temperatures reach below 10°C/50°F to stop lithium plating during next charging cycles.

- The cycling of cells should feature decreased upper cutoff voltages by 0.1-0.2V inside hot temperatures surpassing 35°C/95°F to decrease degradation reactions.

The advanced BMS systems automatically execute these vehicle parameters modifications.

Common Myths and Misconceptions

Multiple enduring misconceptions about lithium-ion battery cutoff voltages need to be clarified because they are incorrect.

Myth: Deep Discharging “Recalibrates” Battery Capacity

The practice of complete discharge for lithium-ion batteries which carried over from nickel-cadmium times actually damages the battery without offering any benefit. Both the process of reaching a fully charged battery and discharge speed up aging management as well as activate BMS safety protection of the battery. Modern battery management systems track battery capacity correctly even without demanding deep discharges from the cells.

Myth: Keeping Batteries at 100% Charge Preserves Capacity

Users continue to keep their devices always connected to the power supply because they think this method extends the battery life. High states of charge above 80-90% rapidly speed up the aging process of the electrodes and electrolyte. The storage recommendation for lithium-ion batteries should fall between 40-60% of their capacity.

Myth: All Lithium-Ion Batteries Have the Same Cutoff Voltages

Each lithium-ion cell chemistry demands its specific voltage range according to what was discussed previously. When using a charger built for LFP that attempts to charge NMC batteries results in conditions that either overcharge or undercharge the battery which reduces performance quality along with safety measures.

Advanced Cutoff Voltage Considerations

Cell Balancing and Cutoff Voltage

The capacity and resistance values of each individual cell in multi-cell battery packs naturally deviate from one another with time usage. The continuous operation of the battery pack will become shorter when differences go unchecked because certain cells will activate their cutoff mechanisms before others. Modular BMS systems now feature balancing hardware which correctly operates all cells between their safe voltage boundaries through these functions:

- Monitoring individual cell voltages

- Charging processes use a system to divert current away from cells carrying higher voltage.

- Small discharge loads should be applied across the higher-voltage cells.

The process of cell balancing makes sure that cutoff voltage rules get implemented thoroughly throughout the entire battery package.

Dynamic Cutoff Voltage Adjustment

The most advanced battery management systems automatically modify cutoff voltages through dynamic controls which respond to various interdependent factors.

- The voltage drops when discharge rates rise because of battery internal resistance but certain management systems react by allowing instant decreases in cutoff voltages.

- Temperature alters the best cutoff voltage settings because it modifies the speed of lithium diffusion together with chemical reaction speeds.

- The adjustment of cutoff voltages becomes necessary when batteries start to age because internal resistances rise.

- Several systems adjust cutoff voltages through usage pattern learning as a method to predict upcoming system needs.

This adaptive system technique allows users to achieve peak performance together with sufficient safety reserves.

Practical Guidelines for Different Applications

For Device Users

- Smartphones and laptops:

- Use the optimization features which manufacturers include in their products

- Avoid frequent complete discharges (below 20%)

- Your devices should stay unplugged between 80 and 90 percent of charge if the location allows.

- Devices must stay away from environments with severe hot or cold temperatures.

- Electric vehicles:

- Users who operate their vehicles daily should enable charge limits between 80 and 90 percent whenever their system permits.

- Refrain from using maximum battery capacity only during extended trips because it provides the most time between charges.

- Store the battery with an approximate 50% charge level when kept in storage.

- Power tools and portable equipment:

- Non-consecutive long-term storage should be conducted with batteries at a 40-60% charging state.

- Batteries should be taken out from their chargers right after achieving full charge status.

- The user must follow guidelines provided by manufacturers regarding minimum operating temperatures for batteries.

For System Designers

- Consumer products:

- Software developers should create adjustable charging restrictions as a feature for programs.

- Engineering of thermal controllers should prevent battery temperatures from straying outside preferred operating zones.

- The design of cutoff voltage parameters should include extra safety values which will compensate for measurement variation artifacts.

- Industrial systems:

- System longevity needs to be placed above maximum capacity output by maintaining conservative voltage limits.

- Implement comprehensive cell balancing

- Critical applications need two independent systems for battery voltage assessment.

Future Trends in Cutoff Voltage Management

Machine Learning Optimization

The introduction of machine learning algorithms into battery management systems enables a continuous optimization of cutoff voltages through analysis of following variables:

- Historical usage patterns

- Environmental conditions

- Measured degradation rates

- Expected future demands

Operational parameter adjustment through systems that optimize lifetime value occurs dynamically based on measured actual conditions rather than rigid fixed rules.

Chemistry-Specific Approaches

The introduction of new lithium-ion chemistries including lithium-rich cathodes along with silicon anodes and solid electrolytes requires an adjustment of cutoff voltage management protocols. Special management strategies exist because each new chemistry has specific voltage characteristics which function through distinct degradation pathways.

User-Configurable Battery Modes

Companies should plan to release consumer devices with an interface that enables users to set their own battery cutoff limits between three management modes.

- Maximum longevity mode (narrow voltage range)

- Standard balanced mode (moderate voltage range)

- Maximum capacity mode (wide voltage range)

Through this approach users would obtain information needed to balance their battery goals and individual needs.

Conclusion

The cutoff voltage of lithium-ion batteries plays an essential role by affecting their operational capabilities as well as their protective measures and their useful time. Multiple factors come into play when implementing lithium-ion chemistries in practice but the absolute chemical limitations define these boundaries. Users together with designers benefit from understanding these li ion cells battery parameters and recognizing what represents a good value to conduct decision-making about battery management systems rechargeable batteries.

The main recommendations for daily users consist of charging devices partially whenever possible instead of draining them completely along with following product specifications from manufacturers li ion battery. The device performance together with customer satisfaction depend heavily on the precise choice of cutoff voltage made by system designers lead acid battery.

Cutoff voltage management becomes an essential practice to optimize energy storage devices which operate our contemporary world and ensure their continued technological progression. Modern technology will develop adaptive optimization capabilities which use actual usage patterns to set cut-off points for battery system performance.