Introduction

Portable power solutions now depend on the lithium ion battery, specifically 18650 battery as their core component which drives electric vehicles and laptop devices. Along with its lithium-ion composition the cylindrical battery gets its name from its dimensional measurements that has now become standard for the industry. A detailed report explains the precise dimensions of 18650 batteries as they influence both system performance and electronic device compatibility within modern applications.

Portable energy storage technology achieved a significant breakthrough through the creation of 18650 battery format development. Sony launched the 18650 cells during the early 1990s with manufacturing ease and compact dimensions and maximum energy efficiency as the designing objectives. Since its debut in the 1990s the 18650 format maintains prominence in various segments of rechargeable battery markets, including high capacity batteries, despite later generation release of alternative form factors. The accurate knowledge of dimensions allows users to select appropriate batteries together with compatible devices.

What is an 18650 Battery?

The cylindrical shape of the 18650 battery contains a rechargeable lithium-ion cell which operates as a 18650 battery. Its dimensions can be read from the numeric designation since it spans 18mm in diameter and extends to 65mm in length. Cylindrical shape is confirmed through the last “0” in the numeric designator, which typically corresponds to the nominal voltage of the battery . The modern battery technology has transformed into a primary energy storage solution because it perfectly balances power density and dependability with its defined physical dimensions.

The batteries feature their constructive elements enclosed within metal materials which include both positive and negative electrodes fused with a separator part joined by an electrolytic component. The anode component normally consists of graphite yet the cathode includes lithium cobalt oxide together with lithium manganese oxide and lithium nickel manganese cobalt oxide (NMC) or lithium iron phosphate (LFP). Performance characteristics of these batteries depend on their selected materials though external dimensions maintain standardization across all manufacturers.

These features derive from the cylindrical configuration which enables both powerful mechanical resistance and streamlined manufacturing alongside dependable operation as well as outstanding thermal efficiency. The metal shell both presents physical protection against damage and performs as the component that carries negative ions. The 18650 design presents exceptional durability that enables numerous applications, including electric cars, leading to its sustained widespread adoption in spite of newer emerging batteries.

Standard 18650 Battery Dimensions

Diameter Specifications

All standard 18650 batteries carry a diameter measurement of 18.6 millimeters which equates to 0.73 inches. Commercially available 18650 cells show manufacturing variations in which the dimensions range from 18.2mm to 18.7mm, although standard measurements specify that the 18650 should be 18.6mm (0.73 inches), reflecting their typical capacity . The small differences in dimensions impact the exactness of battery seatings within particular gadgets.

The diameter assessment only involves measuring the casing since all other materials surrounding the battery are excluded from dimensions. ίαρages provided by manufacturers pertain to the largest dimension of metal cans in their specification. Diameter variations smaller than the standard value lead to performance problems with battery holders, contact mechanisms, and multi-cell arrangements in precise applications, particularly with unprotected batteries.

Diameter control in manufacturing operations has benefited greatly from improvements during the past years. Premium battery producers implement ±0.1mm manufacturing tolerances to produce highly uniform results in each production cycle. The exact measurement plays a vital role in situations when batteries need tight grouping such as electric vehicle modules or notebook battery packs.

Length Specifications

An 18650 battery extends to 65.2mm as its nominal length measure (2.56 inches). The measurements report by manufacturers shows their products fall between 64.9mm to 65.4mm in practice. The length dimension comprises every part of the cell from top to bottom and incorporates the positive terminal (button top) when it exists, which is critical for maintaining voltage .

The exactness of battery compartment requirements depends heavily on the length measurement in device design. Small deviations from the specified measurements will cause batteries to become loose or prevent proper contact, affecting the discharge rate, and lead to poor insertion into designated spaces. The variation in lengths between multiple cells in a configuration can establish unequal pressure distributions which could result in reliability failures.

Each application system gives higher significance to various components of the length specification. Consumer flashlights demonstrate flexibility in dimension compliance as against industrial battery holders, especially when energy density increases, which need exact nominal size following. Organizations that produce original equipment (OEMs) create strict tolerance requirements when selecting 18650 cells for their products to guarantee quality performance and product fittings.

Button Top vs. Flat Top Variations

The button top design of 18650 batteries shows its positive terminal as a protuberance extending from the battery casing. The button top structure protrudes from the battery surface by 1-2mm so it extends longer than flat top versions by that same ratio. The complete length of button top 18650 cells measures between 66mm to 67mm in total.

A raised positive terminal provides important characteristics to batteries. The button top design improves contact reliability across specific devices which include devices that use spring mechanism for negative contacts. Button-top designs protect against reverse polarity mistakes in particular systems, unlike alkaline batteries, because they feature obvious separation between the positive and negative ends. The extra length from button top cells prevents their installation in all 18650 standard-sized devices.

The standard 65mm length for flat top 18650 batteries ensures they have no extended terminal from their body. The positive end of the casing extends completely to the flat surface of the external casing. Flat top formatted cells ensure maximum space utilization thus they find use in battery packs such as laptop batteries and electric vehicle battery modules. Utility density reaches its peak because flat battery cell design eliminates excess space when many cells are clustered together.

The selection between flat top and button top cells depends on how the device was designed for contact and application purposes. Modern high-performance electronic devices utilize flat top cells exclusively but flashlights support both button top and flat top cell designs or they need button tops specifically according to their specifications. A few devices feature adjustable contacts that allow operation under both button top and flat top cell configurations.

Protected vs. Unprotected 18650 Batteries

The protective component inside protected 18650 batteries installs at the negative end to restrict overcharging along with over-discharging and short circuit conditions. The protective circuit surfaces at the battery negative end while expanding it to lengths between 67-69mm and adding 2-4mm to the total length. A protective wrapper installed on protected batteries leads to a minor increase in diameter which ranges between 18.7-19mm.

MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) along with small microcontrollers work in concert with battery measurement elements inside the protection circuit. The electrical connection gets cut by the circuit when operating conditions reach unsafe levels thus stopping possible damage and safety threats. Such protection layers work exceptionally well with standalone systems because they do not possess standard built-in battery management capabilities.

18650 batteries that lack protection retain dimensions of 18.6mm diameter and 65.2mm length. The batteries operate without built-in protection because they depend on external protection circuits in their powered devices. These batteries find their use in battery packs designed by manufacturers because protection circuits are included in the final system design. The lack of protection circuitry elevates energy density while lowering the manufacturing price, allowing batteries to operate at the same voltage .

Protected and unprotected cell dimensions present critical factors which need consideration for compatibility purposes. All devices with exact battery chambers aligned to standard 18650 specifications will reject protected batteries. The protection needs of applications with high-performance flashlights along with other battery-level protection requirements demand cells being longer than 18650. Users need to select batteries based on their device requirements alongside how they will use them.

Dimensional Tolerances and Manufacturing Variations

The manufacturing standards for 18650 batteries enable dimensional variations between +0.2mm and -0.2mm in diameter and +0.5mm and -0.5mm in length. The seemingly small dimensional differences between battery sizes will produce important effects on precision application compatibility. Companies that produce premium products establish close tolerances to create uniform device outputs between their complete range of products.

Multiple elements determine the dimension consistency which manufacturers experience during their production process. Final dimensions of a 18650 battery depend on internal component winding tension and cell crimping process as well as electrolyte filling procedures. The advancement of manufacturing techniques led to the development of better quality control systems which now use high-precision optical measurement devices and automated inspection methods.

The 18650 standard dimensions receive the most rigorous adherence from Japanese and Korean manufacturers but some other manufacturers provide cells with minor dimensional deviation. The specifications of 18650 cells matter most when making battery holders and when different cells connect either in series or parallel fashion. Applications requiring strict dimensional consistency should use cells from manufacturers who demonstrate high manufacturing precision.

The existing differences among manufacturers has motivated some product developers to implement adaptability features in their devices. The combination of moveable battery spaces and elastic contacts having extended travel lengths with flexible cell installations allows equipment to work with different sizes of 18650 commercial batteries without losing electrical stability.

18650 Battery Terminal Design

Button top 18650 batteries present their cathode terminal in dimensions of 3-4mm across the diameter. The positive end of flat top batteries shows a flat contact surface which has a reduced contact space. The positive terminal exists within a 0.5mm elevated position relative to the insulating ring found on flat top design structures.

Different applications receive diverse effects based on their terminal design specifications. A positive terminal needs the right amount of contact surface area and height to stay connected well in diverse electronic devices. The positive cap uses nickel-plated steel from manufacturers to attain durable components and preserve good conductive properties. During the manufacturing process the positive terminal receives a weld attachment to internal parts for establishing a durable electrical junction.

The negative terminal functions as the complete flat base area located at the cell bottom. Maximum electrical conductivity results from the design because it creates broad contacting surfaces. The terminal extends 0.5 mm inside the battery casing perimeter in order to avoid short circuiting. A recess in the terminal design protects from short circuits when the battery encounters conductive objects while establishing a specific contact platform for device negative terminal attachment.

Inside the positive terminal area stands an insulating ring which uses durable polymer materials. The integral element guards against any electrical flow between the terminals while protecting against a short circuit between terminals and metal shell. The dimensions together with structural integrity of the insulator increase battery safety since it functions as one of the key causes of external short circuits within 18650 cells.

Wrapper and Insulation Specifications

An external wrapper of 18650 batteries expands the total diameter by around 0.1-0.2 millimeters. The critical safety and specification data about the battery appears on the thin PVC or heat-shrink material enveloping the metal casing. The positive terminal of the 18650 battery contains an insulating ring that stops any potential short circuit between the terminal and battery housing of the negative terminal.

The new generation of 18650 wrappers contains more components than just insulation materials. Safety information bears legible labels through the combination of tear-resistant elements and heat-resistant coatings and specialized printing methods across the battery operation period. Premium cell manufacturers supply their products with protective layers that increase safety performance by defending against abrasion and chemical contact.

Every cell should come with a wrapper that carries important details about its manufacturer and model number and capacity rating together with the maximum charging and discharging specifications and safety warnings. The listed information enables users to verify the battery and correctly operate it. Manufacturing companies now add authentication elements such as holographic details and QR codes to combat counterfeit battery problems in particular markets.

Maximum safety of the positive terminal depends on accurate dimensional specifications of its insulating ring. Accurate dimensions of this insulator are essential because it must be neither too thick nor too thin as they affect the positive terminal’s contact points while under stress. The insulating ring requires high-temperature polymers from manufacturers for maintaining its insulating function under thermal stress conditions. This insulator requires precise dimensions which determine the safety and reliability traits of the battery system.

Impact of Dimensions on Capacity and Performance

Standardized dimensions of 18650 batteries present technical hurdles for engineers. Maximum power delivery capability together with safety standards must be balanced with energy storage capacity in the predefined volume by manufacturers. The target capacity specifications of high capacity cells exceeding 3500 mAh are accomplished through density optimization of active materials while minimizing built-in structural elements which results in reduced maximum output rates.

The confined space of 18650 batteries requires all its components to fit within specified dimensions. Every element of the battery including the cathode and anode materials together with separator and electrolyte solution and current collectors needs to match the established sizes. Higher capacity cells install thin separator and current collector elements to optimize active material density. The selected modifications lead to reduced mechanical strength as well as deteriorated current-handling performance.

The structural elements of low-power cells (2000-2500 mAh) receiving high discharge currents need enhanced robustness to face greater current levels in their standard formats. Several safety features together with robust tab connections and thicker current collectors appear in these cells. A central engineering issue evolves from designing between battery capacity together with power-handling characteristics inside the standardized 18650 dimensions format.

The design components within the battery receive direct influence from temperature management. The operating heat must be properly carried from the interior to the outer case surface for cooling purposes. Special internal features included in power cells enhance thermal conductivity while simultaneously decreasing available active materials space yet enhance safety performance and product durability. The mandated external dimensions shape the development of innovative solutions within the internal components.

Applications in Consumer Electronics

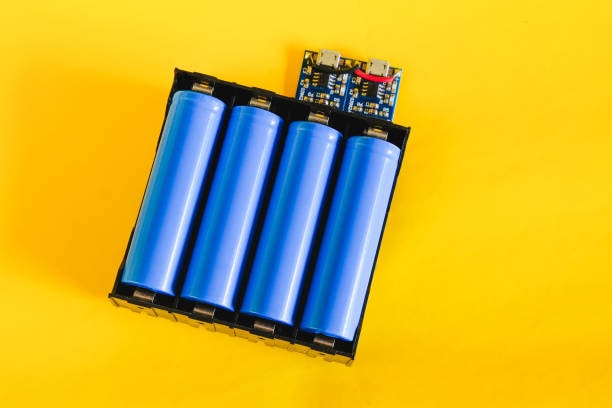

Laptops together with power banks incorporate customized arrangements of 18650 batteries as their power source. The electronic systems need batteries arranged in precise dimensional arrangements because they operate within tight areas where clearance is minimal. Multiple consumer devices possess protection systems that are built into their structures to support the use of flat top cells with standard dimensions.

The laptop computer serves among the primary initial uses of 18650 batteries. Production of a typical laptop battery pack involves at least four but not more than twelve individual 18650 cells which are connected in parallel and series arrangements to generate the needed voltage and capacity values. The battery pack housing consists of plastic cell holders that precisely fit the batteries between them while enabling small thermal expansion movements.

Portable power banks adopt the 18650 cell technology because it offers excellent energy density alongside standardized dimensions. Announcements that use 18650 cells typically arrange from one to eight units based on their capacity goals. Standardized dimensions of 18650 batteries enable circuit board and enclosure developments for various applications including portable power tools, while increasing manufacturing effectiveness and reducing production expenses.

Standard consumer products that use high-performance flashlights along with portable fans and cordless personal care devices depend on 18650 batteries to function. The applications that use 18650 cells harness their high energy density together with dependable performance and extensive commercial availability. Manufacturers can design their products following pre-defined dimensions because this facilitates development work while granting replacement capabilities to end-users.

Use in Electric Vehicles and Energy Storage

Tesla utilized thousands of 18650 cells when they built the battery packs for their Model S vehicles. The applications require thermal expansion management so cells need specific clearance between each other. Dimentional consistency represents the core requirement for safe operation and performance in EV cooling systems which were designed to suit the specific measurements of 18650 cells.

A Tesla Model S battery pack normally included around 7,000 individual 18650 cells put into modules. This design methodology brought multiple benefits since it generated efficient cooling through cellular channeling while using standard production cells with quality control standards and offering built-in redundancy through solitary cell failures. Cell dimensions became vital information because they needed to be calculated for the thousands of units being used.

Different forms of electric vehicles and hybrid systems use 18650 batteries for their assembly. Automated assembly together with quality control procedures become simpler because of standard cell dimensions. Several manufacturers implement larger format cells like 21700 but they maintain their reliance on 18650 cells because these units show track record reliability alongside mature supply networks.

Massive deployments of 18650 cells power the storage systems operating at a grid-scale level. The facilities house arrays of carefully designed individual cells that reach numbers into the thousands. Standardized battery dimensions make it possible to build modular systems through which individual battery components can be produced separately before their final integration. The ability to break down parts coherently enables painless maintenance and gradual power capacity growth throughout system operation.

Dimensional Compatibility Challenges

Equipments that function with 18650 batteries cannot support protected cells because protected cells extend in length beyond standard specifications. The physical contact between button top cells and devices fails when those devices are built for flat top cells. Specific dimension requirements between batteries and their power devices require thorough understanding to ensure proper connection between these elements.

Users face compatibility problems when they choose aftermarket batteries instead of original ones to replace them. The manufacturer designed certain dimensional parameters which they did not fully disclose to their end users. The combination of button top and flat top cells results in improper electrical contact because a flashlight built for button top batteries would not make correct electrical connections to flat top batteries though they are both 18650 types.

Magnetic spacers function to connect flat top batteries with devices that need button top installations in cases when their lengths differ. A diameter solution might be found through using thin wrappers to address restricted insertion problems. Careful attention should be paid when modifying batteries or pushing them into constricted areas because such modifications involve potential safety hazards.

Cell-to-cell usage in series configuration creates another notable challenge for battery implementation. The small difference in cell lengths causes unbalanced pressure distribution within the battery pack leading to possible safety or premature degradation problems. Professional battery pack manufacturers establish length-based sorting procedures to assemble cells with uniform sizes within each unit.

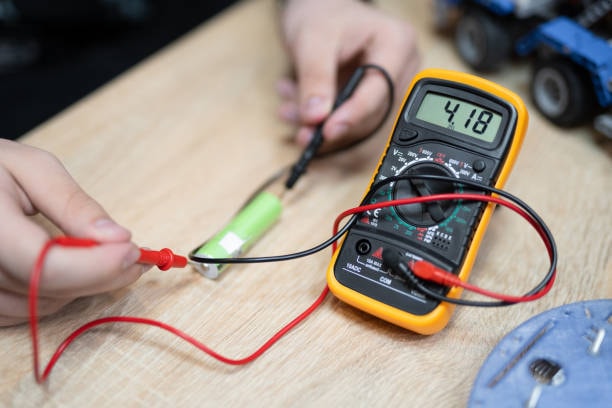

Measuring Techniques for 18650 Batteries

Digital calipers represent the necessary tool to measure 18650 batteries precisely at a 0.01mm scale. The measurement of length requires inclusion of the positive terminal extension while omitting external points unless they are parts of the battery device. Measurement of diameter needs to be taken at the widest point while disregarding the wrapper seam because it produces small irregularities.

It is essential to distinguish between the protected battery protection circuit and the location of the device contact points before measurement procedures begin. The protection circuit forms part of the battery length after which all external features such as spring contacts become excluded. To determine button top cell length the measurement should consider the protruding button button as part of its complete dimensions.

The dimensions of objects change because of thermal expansion impacts. Batteries need standard measurements at room temperature (20-25°C) after resting for a minimum of one hour. The thermal effects from charging or discharging operations lead to slight variations in measurements that occur when measurements are taken right after charging or discharging especially with high-power cells which create substantial heat during their operational period.

Testing laboratories that specialize in battery evaluation primarily employ automatic measurement tools to achieve continuous accuracy. Optical measurement techniques operate in these systems because they prevent deformation of soft wrapper material through contact inspection methods. Measurements need to be performed at several points across the battery circumference for best accuracy since manufacturing may create asymmetrical features in the product.

Evolution of the 18650 Form Factor

Introduction of the 18650 form factor delivered dimensions which experienced minimal change throughout several decades across its usage period. The cells maintain backward compatibility because their dimensions have stayed constant while their internal design has undergone significant developments. Contemporary 18650 cells manage to double the energy storage capacity from initial versions but preserve their original dimensions.

New 18650 cells received their market introduction in the early 1990s with an operating capacity range between 800-1000mAh. Modern high-capacity lithium cells, specifically 18650 cells, became capable of delivering 3000-3600mAh through continuous material and manufacturing refinement without resizing their physical structure. Technological advancement received its stable foundation due to the standardized form factor which led to this major performance improvement.

The industry conducted research into alternate sizes by developing the 21700 (21mm x 70mm) format which Tesla includes in their newer vehicles and many power tools. Mass manufacturing of the 18650 remains strong because existing production lines produce billions of units annually for devices which use its common format. Annual production runs pass the billion-unit threshold to make this battery type one of the most commonly manufactured formats worldwide.

The 18650 format remained resilient against predicted format replacements thus it maintained its successful position in the market. Its production infrastructure combined with proven reliability together with massive installed device compatibility establishes the 18650 battery format as relevant for future usage. Energy density benefits of the 21700 format do not outweigh its production limitations which result in better manufacturing quality and lower expenses.

Comparing 18650 to Alternative Battery Formats

Higher capacity measurements up to 4000-5000mAh for 21700-type batteries are possible because this format gives 50% additional space over 18650 designs. This larger regulatory size ensures better energy density as well as better heat management through improved surface-to-volume ratio.

The 26650 battery extends 26 millimeters wider than the 18650 battery while keeping its length at 65 millimeters. Applications that need high capacity delivery along with maximal current levels tend to use this cylindrical battery design when diameter limitations do not apply. Because of its strengthened diameter the 26650 offers double the volume of an 18650 so it can hold 4000-6000mAh.

The 14500 (AA size) and 10440 (AAA size) cylindrical cells deliver 18650-type chemical properties in miniature packages that are easier to fit into compact spaces. The compact form factor of these alternative cells decreases their size instead of reducing capacity so they match requirements where space takes precedence. eel batteries under the format 14500 deliver 800-1000mAh capacity while the 10440 cells provide 350-600mAh.

Applications that need efficient use of space accept rectangular prismatic cells in several different dimensions new battery. These battery formats need custom manufactured housings and temperature control because they do not share 18650 cell standards. Placing modern pouch cells in systems requires detailed attention to both structural support systems and implementation pressure control due to their superior energy density and flexible design nominal capacity most electronic equipment.

Safety Considerations Related to Battery Dimensions

The cylindrical form of 18650 batteries makes them structurally resistant and provides built-in pressure dispersal functions which activate after internal failure occurs electrochemical society

. A rigid steel coating of the cells enables high tolerance to rising pressures until collapse occurs at predetermined vulnerable points where directed energy disperses safely digital cameras.

Repeating the correct distance between 18650 cells during system design allows both thermal expansion and heat dissipation to happen more effectively more capacity. Standards within the battery industry advise that cell spaces in battery packs should maintain at least 0.5mm distance for pressure reduction and thermal expansion requirements lower resistance larger diameter. Commercial battery packs include thermal pads and heat-conductive materials besides standard features for distributing temperatures between multiple cells remote controls.

The standard dimensional requirements of 18650 batteries contain hidden safety features which are not self-evident to the user full discharge. A recessed negative terminal design prevents short circuits accidentally while a positive terminal insulating ring ensures electrical separation of terminals voltage range. The tiny dimensional attributes provide substantial contributions toward making the battery secure non rechargeable more energy.

Counterfeit or substandard 18650 batteries show minor deviations in their dimensions which users cannot detect easily. The manufacturing of substandard 18650 cells, unlike button cells, involves lightweight casing materials together with omission of safety features and use of inferior insulation materials stronger heating. Users should select batteries from both reliable manufacturers and distributors because dimensional compromises directly influence safety performance higher polarization.

Future Outlook for 18650 Dimensions

The industry evolution of 18650 cell internal features occurs alongside maintained dimensions of their external structure. Industry analyses indicate the 18650 format will persist in the market at least during the next ten years despite the rising popularity of newer form factors battery management system. The broad device ecosystem based on this standard will sustain its production while market share declines because new formats deliver better energy density slightly larger.

Moving forward 18650 battery research will concentrate on generating greater energy density by using innovative materials instead of dimensional size evolution. The combination of solid-state electrolytes and silicon-composite anodes and high-nickel cathodes shows potential to boost battery cell capacity, resulting in increased capacity while preserving the regular format dimensions. Technology innovations show promise to increase 18650 lithium-ion cells above 4000mAh capacity without alterations to their dimensions jelly roll.

Manufacturing technologies will most likely lead to smaller variations between cell dimensions when compared to those of manufacturers. The market will experience enhanced consistency due to higher automation levels together with better quality control systems and standardized testing protocols. Device manufacturers together with consumers will experience better battery source reliability because of this shifting trend.

Despite the adoption of 21700 by some market segments the 18650 format will maintain its established dominance in battery technologies aa battery. The 18650 format remains relevant because of three main factors: massive device compatibility and robust manufacturing systems and ongoing advancement of performance capabilities.

Conclusion

The standardized dimensions of 18650 batteries resulted from a long period of engineering work which enabled the portable electronics revolution to advance. The comprehension of these standardized battery dimensions grows crucial because it benefits producers and end users among them. The precise measurements of the 18650 battery have proven over time how standardization enables progressive development while enabling compatibility with past technologies.

The 18650 format achieves outstanding standardization together with adaptability through its dimensional specifications. The basic design standards maintain uniformity for product developers yet the various terminal options and protection modules serve different usage needs. Through this measured combination of standards the format has gained persistence while it has spread throughout multiple commercial sectors and functions.

Understanding the dimensional aspects of these cells becomes essential for both users and operators of power devices because it guarantees peak functionality together with secure device operation. The dimensions defining 18650 batteries play an essential role in present-day portable power systems since they shape future energy storage designs up to the next several years.