Whether someone gives enough thought to the battery internal resistance of a lithium battery is a big factor in its overall performance, efficiency, and aging. The resistance in lithium ion battery systems prevents electric charge from going through them. Resistance inside a battery appears no matter if it is alkaline, lithium-ion or lead-acid, affecting all sorts of batteries. Battery designers and users must all be aware of internal resistance, as it influences how a battery charges, delivers energy, heats up and stays reliable today.

As the battery grows older, it may deliver much less power during situations that require a lot of electricity. When devices face too much internal resistance, this internal resistance increases and e battery’s ability to perform diminishes, resulting in a voltage drop that decreases and can cause their work to slow down or turn off instantly. If you charge and discharge your battery a lot, it will quickly get hot and may suffer damage. When rechargeable batteries have less battery capacity, they charge slowly and don’t hold much of a charge. Spotting internal resistance often helps individuals see early signs and plan to manage their habits in a better way. Being aware of battery condition and internal resistance allows you to use your battery more safely, for a longer time and more efficiently.

What is Internal Resistance in a Battery?

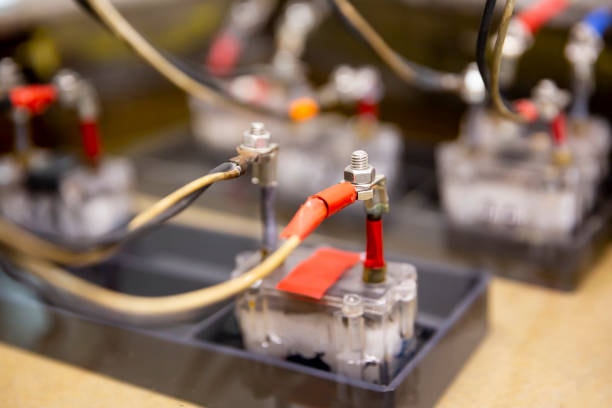

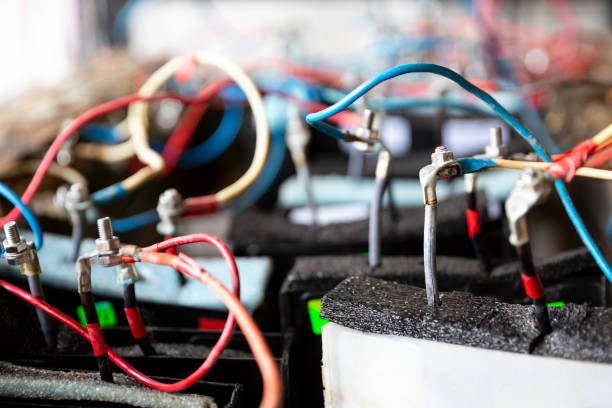

All the resistance forces found inside a battery pack that prevent electrons from moving from anode to cathode through the electrolyte and other parts are called the internal resistance. Electrolyte resistance, resistance at the electrode-terminal point and basic electrode resistance are the main causes for internal resistance. Energy from the battery is lost when it encounters internal resistance and that energy is typically turned into heat that decreases how efficient the battery is, making internal resistance calculation crucial .

What’s more, inner resistance increases as time goes by or when temperatures are very low or high loads are placed on the batteries. When resistance gets higher, the voltage under load is more noticeable, leading to the battery being unable to furnish enough current to devices. Not only does this shorten runtime; it can also cause your system to shut down quickly which is very common in power-sensitive hardware. Since high resistance makes testing harder to trust, it’s usually necessary to apply a load during testing, a procedure also known as a load test, to get a proper assessment of a battery. This is why it is important for engineers and battery users to keep an eye on all three: low internal resistance, capacity and voltage in the battery. Extending the life of your handheld device and improving battery performance depends on proper charging practices and preventing internal battery resistance through good design and care.

How Internal Resistance Affects Battery Performance

As a battery pack is used, resistance inside it regularly begins to increase the longer it remains in use. The internal resistance of electronic devices, alongside battery voltage, is measured in mΩ and may be found by different methods. Advanced testers measure battery impedance by applying alternating currents, but simpler devices use a comparison method using standard references. High resistance inside a battery can result in a hefty discharge current during great efficiency demands, especially as cells age causing the battery to fail and not delivering enough power to the device. This effciency drop can be seen in softer lighting, slower boot up times for devices and fewer hours of proper use.

In addition, higher resistance inside the electronics leads to poorer performance and faster battery aging thanks to the additional heat. Such heat in nickel based batteries may cause both physical and chemical changes inside the battery that increase the loss of energy in the battery. bearing high levels of vibration can cause major problems in devices used in medicine, disaster situations or advanced electronic products. So, using smart chargers and battery analyzers for checking internal resistance regularly allows companies to spot if a battery is likely to fail and make timely replacements. Keeping an eye on this little-noticed parameter allows users to keep their batteries charged, stay safe and avoid interrupted use of vital devices.

Measuring Internal Resistance

Both direct and indirect ways can be used to measure milliohms of internal resistance. Advanced devices use AC to estimate impedance, while classic instruments measure how the direct current voltage changes when charged and uncharged. To compute the internal resistance you use the formula, R = (V_no-load – V_load) / I_load, which is an essential method to measure resistance in battery systems . These measurements, including measuring the internal resistance, are based on technology, but users rely on them to find out the health of their lithium battery and arrange necessary maintenance or replacement when needed.

As well as measuring a device, recognizing internal resistance enables users to relate their symptoms to problems with the battery. Most often, when voltage decreases rapidly under stress and charging overheats the device, internal resistance is increasing. Users can use these metrics, including discharge curves, to see how the system is improving or declining, guess when problems are close and address them before they become critical. Consistency matters the most in expert roles which is why this is especially worthwhile there, especially when assessing voltage output . Furthermore, adding internal battery checks to routine maintenance supports energy efficiency and leads to better performance, making batteries last longer in multiple applications.

Factors That Influence Internal Resistance

Both the design and what a user does can contribute to the battery’s internal resistance. Changes in temperature tend to alter the battery’s inside resistance. A low temperature causes ions to move less within the electrolyte, and as a result, internal resistance increases, creating high resistance in the internal circuit. As the temperature grows, the internal resistance decreases – yet, more heat causes thermal strain and threatens the service life of the battery. Not only does temperature and the design matter, but also the way a battery is produced and how it ages influence its internal resistance, especially when an external load is applied .

Also, electrode area, good-quality separators and electrolyte properties are part of the baseline internal resistance determined by the battery’s structure. As a battery gets older, chemical processes like the SEI layers, corrosion and electrode changes cause resistance inside to go up. Frequently going past 100% on your phone, charging it often and unpredictably or overcharging it, usually causes it to age more quickly. Moisture or vibration in the area can make things worse for circuit boards. Being aware of these influences, users and engineers are able to apply better ways of handling batteries such as controlling how they’re charged and controlling their heat, taking into account voltage difference o protect performance and extend their life.

Internal Resistance and Charging Efficiency

The resistance on the inside can lower both the discharge and charging of the batteries. When a battery’s resistance increases due to direct current , it becomes hotter as it charges. All this extra heat wastes energy and, if not well-managed, can progressively make the battery components weaker or cause the electrolyte to dwindle. Such resistance can sometimes bring an electric bike’s ability to calculate internal resistance, leading to significant heat generation that brings its charging to a forced stop in the battery pack or creates sudden interruptions during the Riding charging process. Efficiency of charging the batteries is greatly improved when the internal resistance is reduced by employing a resistance method .

Moreover, higher internal resistance stops the battery from sending out high current during heavy use which reduces the power of hungry devices. Such an issue is most serious when high-drain devices like power tools or electric vehicles are used, as losing voltage under load can cause early malfunction or a failure to run. When the current load increases, terminal voltage sag becomes stronger and devices either run less efficiently or activate low-voltage protection circuits, impacting the overall current flow . In order to address these issues, both battery makers and users work on methods that lower both heat and resistance. A key point for batteries is to keep the battery internal resistance low internal resistance to maintain both the capacity and dependability of the battery year after year.

Implications for Battery Life and Maintenance

Noticing any inside resistance is necessary for batteries to live a long life. Routine testing of solar power storage and auxiliary power systems helps to find resistance problems before they cause major problems, allowing users to effectively test internal resistance. Frequent increases in discharge cycles and battery resistance often suggest that there is a problem, either sulfation of electrodes in lead-acid batteries or loss of active material in lithium-ion ones. Early detection of resistance growth by operators enables them to act rapidly, for example by balancing the lithium ion battery, reconditioning or substituting the battery head to protect the battery from big issues.

Additionally, keeping an eye on internal resistance trends over periods of time shows how old the battery currently is and how long it can expect to last. When logged faithfully, these measurements help technicians arrange maintenance for the given battery before equipment fails. To guarantee continuous and safe operation in fleet management, telecoms and UPS systems, being aware of normal internal resistance is very important. Smart batteries and data logging technology can handle monitoring and send warnings in real time, along with full reports. Paying attention to internal resistances helps users avoid reduced performance, getting better battery performance, higher energy usage efficiency and stronger system reliability, including in crucial and everyday operations.

Design Strategies to Minimize Resistance

Thanks to advances in using science, engineering and design, the industry is finding ways to drop energy-waste within vehicles. Better results in cells are brought about by improved shapes of the electrodes, enhanced characteristics of the electrolyte and higher quality interfaces. By using additives that conduct or managing lithium ion battery terminals by changing the structure of electrodes, we can significantly reduce internal resistance. As a result, lithium ion cells charge faster, discharge more efficiently and hold the voltage steady with a load.

Furthermore, recent progress in nanotechnology and material coatings helps to cut down the internal resistance through more efficient power flow throughout the entire battery. Graphene-based electrodes and solid-state electrolytes suggest ways to make the batteries more durable, less resistant and safer. Advances in materials enable li ion battery systems to take more current with less heat, which extends both their useful lives and steady performance, and allows for better assessments with a battery tester . Using these leading materials and approaches in manufacturing, including addressing the resistance of lithium ion the industry delivers better, quicker-charging and durable batteries suited to the increasing needs of electronics and electric cars.

Internal Resistance in Different Battery Types

All batteries encounter some internal resistance, but how much and in what form this resistance appears is not the same for every battery. The resistance inside lead-acid batteries is almost always greater than that found in lithium-ion or nickel-metal hydride ( NiMH ) batteries. Since situations that need charging fast or strong power require low resistance, open circuit voltage is a critical factor, and lithium-based chemistries are used. Similar chemical, design and quality properties can also show different internal resistance and reliability due to the effect of environmental factors, which can be verified by a dc reading .

Besides chemistry, temperature, the state the battery is charged to and the age of the battery play roles in affecting when internal resistance will rise or fall. The ageing of batteries tends to raise their inside resistance because materials within the batteries deteriorate. Rising obstacles within your lithium ion batteries can prevent them from running full capacity, charging slowly and delivering less strength. It is very important to recognize how internal resistance affect performance and these variations to know how your battery is operating, so you can decide on the right approach for its maintenance, swap-out, or optimization of the internal resistance of a battery.

Conclusion

How quickly or slowly a battery can charge has more impact on a test than its designation might suggest. Changes in internal resistance modify the output voltage, total power, heat that the battery generates and reliability over time. By handling the resistance within a battery more wisely, it gets longer-lasting usage, smarter care, accurate measurements and better maintenance routines.

Besides, following the output of internal resistance closely lets users and manufacturers notice any changes in battery health before there are noticeable performance issues, including considerations of specific gravity . Doing this helps you avoid surprises and select ways to charge and use the phone that don’t overstress the battery. In the end, good management of ohmic resistance and internal resistance improves safety, maintains dependability and lengthens the lifetime of batteries used in many applications.