What Does Connecting Batteries in Parallel Mean?

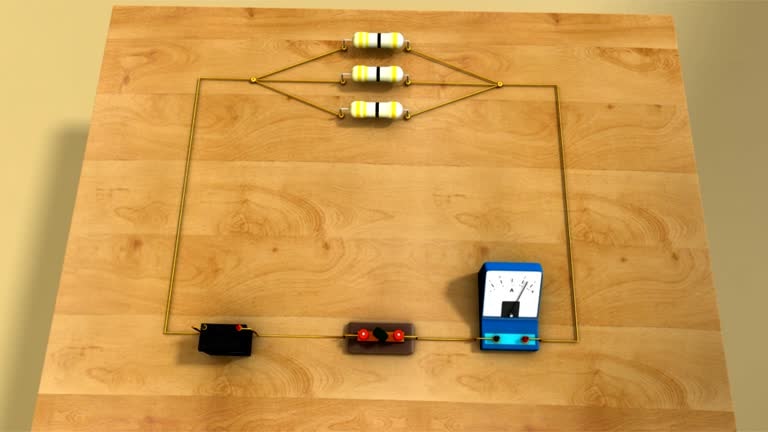

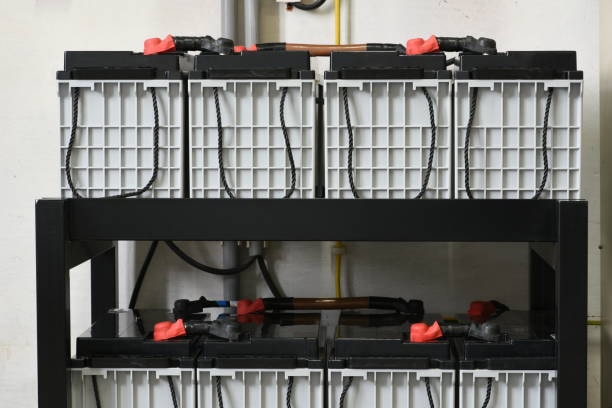

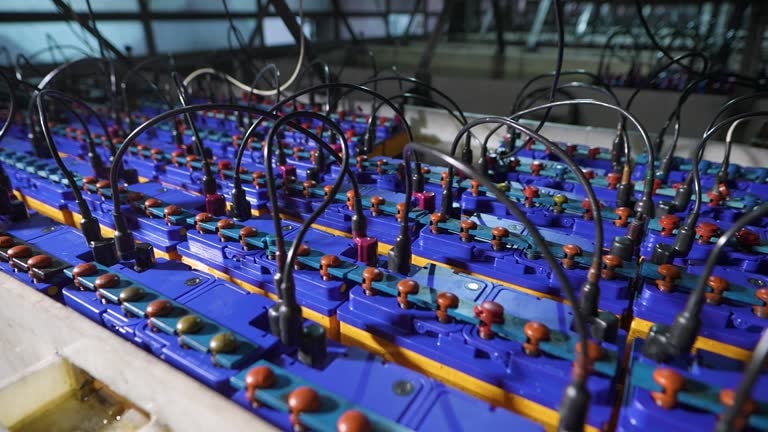

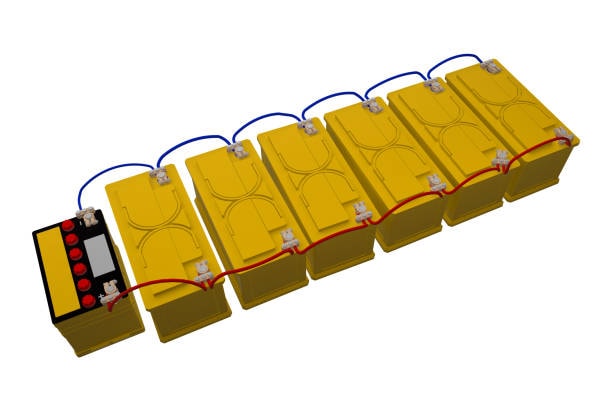

Linking two lead acid batteries in parallel means connecting their positive terminals together and the negative terminals together, too, while understanding the distinction from batteries in series . Two batteries connected this way keep the same voltage as one battery, but double the overall ampere-hour capacity. This system is mainly used to provide a longer run time while preserving stable voltage, making it perfect for situations where both the voltage and running time matter.

If kept in parallel, multiple batteries connected share their current capacity, enabling the load to use energy from all batteries at the same time. In other words, the batteries are lightly used which improves the performance of the battery bank as a whole. When using two batteries in parallel, two 12V 100Ah batteries give 12V voltage and 200Ah capacity, thereby putting double the amount of power at your disposal for use.

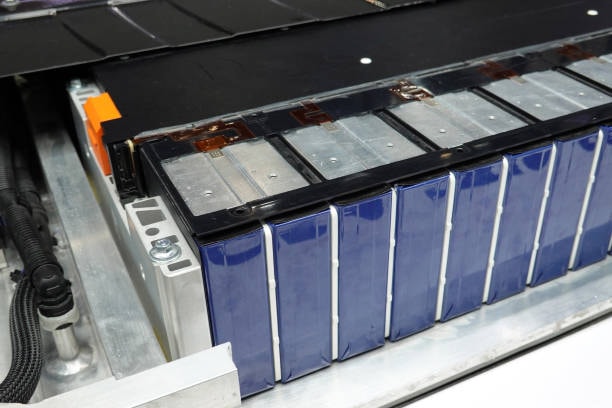

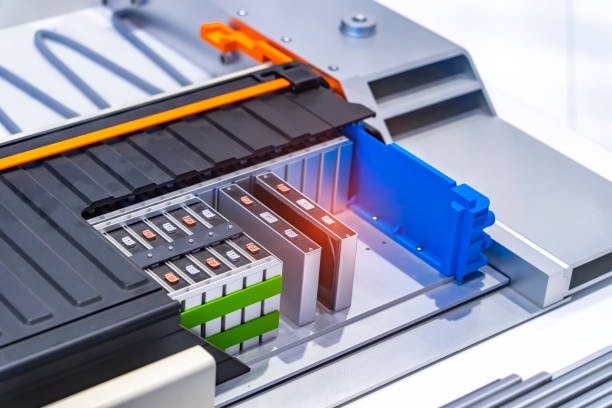

Many solar power systems, including lead acid solar panel setup UPS and electric vehicles rely on this parallel structure to gain more sustained energy without using higher voltage. Anyone involved in making or maintaining battery banks should know about the battery monitor, since it provides flexible means to satisfy various power requirements; for more info, users can consult battery management resource .

How Voltage and Capacity Behave in Parallel Connections

It’s very important to realize the way voltage and capacity work differently in parallel compared to configurations like batteries in series. And when you have a parallel connection, all the individual voltages are the same as the voltage from just a single battery. If you join 12-volt batteries in parallel, their combined system will still be 12 volts, no matter how many batteries are in the group.

In a parallel configuration, the total capacity or amp-hour rating is significantly different. The whole battery system has the combined capacity of its single batteries. A bank created by connecting four batteries with a high battery capacity in parallel will hold 400Ah at 12V. A battery bank can extend the time a device can operate, as it keeps more energy on hand for all those moments it’s used.

It is for this reason that extending running time without raising the voltage is simpler when a parallel connection is used to support the load . At the same time, this means the charger must be able to give out enough current to support charging all the batteries and the appropriate cable size must be used to compensate for any voltage drop that may occur.

Advantages of Connecting Batteries in Parallel

An advantage of paralleling batteries is that the charging current capacity rises, while the voltage is not affected. By using this system, users can run their electrical systems longer which is necessary in off-grid solar, lithium batteries electric cars and backup supplies. When several interconnected batteries are used together, the length of available energy increases, lowering the need for frequent recharging and keeping the system more reliable during tough times, ensuring maximum performance .

Another advantage is that batteries now carry less current. Because the current from the battery bank is distributed equally among the parallel batteries, each one experiences reduced stress while being used. Because different cells are each used at different times, they are less exposed to overheating and rapid degradation caused by too much current. That’s why interconnected batteries in parallel connections work well when power and safety matters are at the forefront; incorporating a switch can further enhance safety .

Besides, building several batteries in parallel gives more options for increasing battery size. You should find it easy to raise the capacity of a parallel bank, as long as you use batteries of the same type that match the others in terms of voltage and capacity. Because parallel battery systems can grow in capacity easily, users who foresee their energy needs increasing in the future can upgrade their system without having to change out all the batteries; for more info, users can consult battery management resourc .

Potential Challenges When Connecting Batteries in Parallel

Even though there are many advantages to using batteries in parallel, users must be mindful of specific problems that can occur. Making sure all batteries are the same voltage, have equal capacity, and are the same age is one of the main things to consider before connecting them, avoiding those with different voltage to prevent any mistake . When you have mixed batteries, the process of charging and discharging can be unequal, with a few batteries overworking and the rest only partly discharged. If the batteries are not equally charged, it can lead to damage of the weaker ones and eventually run down the battery bank’s system.

A third issue can occur when batteries do not share current evenly because of differences in their internal resistance. Minor differences between identical batteries can make some batteries able to send more current than others. If the thermal management system does not work, and there is a significant voltage difference between any individual battery, the device can get too hot, possibly reaching the maximum heat threshold the battery can fail earlier and it may become dangerous. A way to deal with this is to wire things properly to avoid any risk of a short circuit , maintain your battery bank’s balance, and if needed, install a battery monitor system.

Care should be given when charging batteries connected in parallel. All the batteries must be charged evenly by the power source or the charging system would not be complete. When a charger is unsuitable or its regulation is inadequate, a few batteries may not get fully charged and some may become overcharged, particularly affecting the battery terminals . As a result, the system starts to lack space and is less productive over the long run. Because of this, using a quality and proper charger along with the right size fuse with the battery bank is vital to keep parallel-connected batteries in good shape.

Proper Wiring Techniques for Parallel Battery Connections

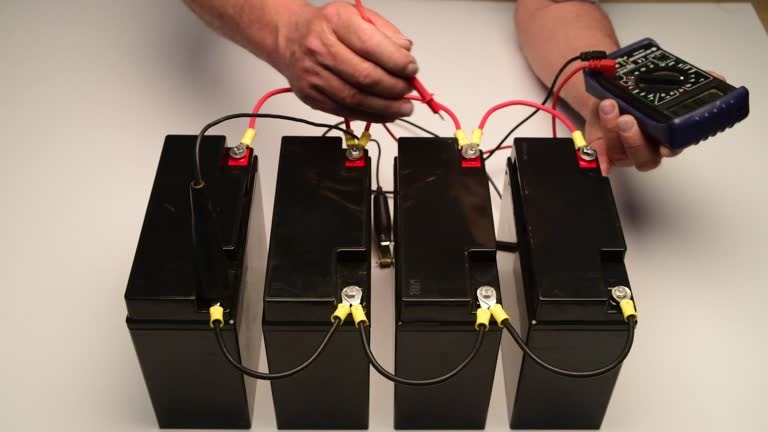

Wiring must be correct when hooking up batteries in parallel to protect yourself and use the batteries properly. This means your cables have to be strong enough to support the highest level of expected current, especially when many batteries connected keeping voltage drop and heating under control. Using thin wires in your house can waste power and make fire safety a concern. The size of the wiring should reflect the total amperage your battery bank can provide, factoring in the capacity of each individual battery, and you are advised to look at wiring charts or ask professionals before deciding.

In a parallel connection, connecting the positive terminals of the batteries with each other is necessary, as with the negative terminals. Make sure that the wires go from one end of the battery to the other and connect at two terminals so every battery spreads out the load equally, which is different from using batteries in series . With this, you need to keep wiring distances as similar as possible to avoid differences in voltage and make sure each battery shares the same amount of current. Achieving this balance becomes much easier if you use a shared bus bar or terminal block.

It is also important that all joints are secure and not corroded to stop unexpected resistance from forming and making the surface hot. Often checking the wiring and terminals will help detect if there are any early signs of damage. Make sure wiring is held in place correctly, especially when integrating a new battery, or else it may move and make electrical connections come loose or fail, causing sparks. Using these ways of wiring your battery bank makes your battery system safer and delivers more energy.

Safety Considerations When Using Parallel Battery Banks

Since harm can come from errors while working without much experience, safety should be your main concern when handling batteries set up in parallel. Good battery safety includes giving the old battery and other batteries enough ventilation to eliminate potential gas buildup while they are charging or discharging, which can be achieved at low cost . If you keep your new battery alongside othe batteries well ventilated, they are less likely to explode and will function well, lasting longer.

It is important to have fuses or circuit breakers protecting every battery or the complete battery system. They serve to prevent excess power from flowing and possibly hurting a new battery or cables and causing fires, particularly by monitoring battery voltage . If there is a fault, such as a notable voltage difference the fuse will burn out or the breaker will open to separate the problem and shield the other parts. Having this protection is especially necessary in big banks of batteries or high power applications.

Don’t forget to use insulated tools and safety gear each time you work on battery systems to prevent accidental battery shorts or shocks. Be sure to refer to the battery instructions by the manufacturer when handling, charging or taking care of your device. Managing parallel battery banks requires being well aware of battery safety, particularly regarding each individual battery . When you follow these steps and include a switch , you reduce your risk for accidents and can depend on your battery system for a long time.

Importance of Battery Matching in Parallel Configurations

It is very important to match batteries before attaching them in parallel to keep the system reliable and lasting. It means selecting batteries with the same voltage, how much they store, what they are made of, age and origin brand wherever possible; an example would be choosing two identical lead acid batteries . If batteries have different charges, the one with the most power will work hard, while others will be left idle and worn out quicker. Uneven distribution of work can lead to inefficiency, a decline in whole capacity and even lasting harm to cells.

Should a fresh battery with small resistance be placed in parallel with an older one, the newer one will be more burdened, empty out faster. When the engine does not receive force evenly from the second battery , both wear and overheating could result. With every passing period, the system is under more pressure because of its unbalance. Sometimes, if the values are far apart, it may cause equipment to close down to protect itself, reduce its ability to deliver or create a risk of short circuits.

Making sure the batteries are well paired before connecting in parallel guarantees each cell will power the system the same. As a result, your device’s performance improves, battery life extends and charging it is less complicated. When you don’t have exactly identical batteries, such as in an example of mismatched batteries, using the first battery’s charge level as a baseline a battery management system or balancing circuit can help.

Role of Battery Management Systems in Parallel Setups

Safety and efficiency are maintained because of a Battery Management System (BMS) when batteries are joined in parallel. The main job of the battery management system is to watch and manage crucial battery factors such as voltage, current, temperature and state of charge. For this reason, the BMS checks each battery and makes sure all cells are prevented from becoming overcharged or undercharged while also providing a smoother battery life.

A problem with parallel batteries might occur when their inner resistance or charge levels are a little off. A BMS fixes this problem by equally distributing charge in the batteries, making each one perform the same and keeping individual cells from ageing quickly. Some systems are equipped to detect a faulty battery and shut it off to keep the rest of the pack working and safe.

Besides, the BMS plays a role in safety by overseeing both temperature and circuit protection. Should it sense overheating, too much current or a quick decrease in voltage, it takes action by breaking the circuit. Due to the increased capacity and complexity found in solar panel energy storage, electric vehicles, and systems with multiple batteries in parallel, greater automation and protection are highly needed.

Monitoring and Maintaining Parallel Battery Systems

Proper monitoring and maintenance will ensure the batteries in a parallel group keep running and are safe for use all the time. Regardless of equally matched batteries and a well-designed wiring system, the system may perform worse as it ages, is exposed to the elements or more charge cycles take place. When tiny issues are missed by ongoing monitoring, they may grow into breaches that can harm the battery system’s work and durability.

Checking the battery voltage on every battery is the first thing to do in routine maintenance. All parts of a functioning parallel setup should have close to the same voltage whether the system is idle or operating. Important differences in the numbers can indicate that there is a problem. Furthermore, making sure each connection is secure prevents anything from wearing or corroding which might increase resistance and cause dangerous faults. By keeping ends of cables free of dust and rerouting the wires as necessary, you can ensure that adequate power is supplied and always get good performance.

In addition, monitoring temperature is important in places where currents are high or systems run for a long period. If the cabinet doesn’t heat the same way, it might mean there’s a concern with some cells or wires, particularly due to varying internal resistance . Having thermal sensors or infrared equipment lets one notice hotspots before they become serious. Learning patterns from the battery’s performance, when it is charged or discharged and what maintenance is done can assist with finding the best time to replace or upgrade.

The Science Behind Equalizing Battery Charge

To function correctly together, all batteries in a parallel group need to be charged to the same voltage. When batteries share the same charge, their energy is assigned evenly so that each unit operates properly. The lack of equalization can result in one or more batteries being too full or too empty which can quickly harm and possibly fail some of the battery pack. In systems where the batteries are old or their capacities or internal resistances are not the same, such as with a solar panel setup this is more important.

There are passive and active ways for equalization to take place, such as using an active balancing circuit . It is sometimes possible for batteries to balance when in parallel and idle for quite a while—weak batteries receive charge from stronger ones over the course of the wait. The process, though, usually takes a while and is not always consistent. Active equalization, by comparison, uses special quality components or a BMS which helps redistribute the charge more efficiently for a quicker and safer balancing of each battery cell.

Maximizing performance and lifespan depends mainly on ensuring your battery is charged equally, especially when using three batteries . If your batteries have the same charge, they will release it evenly, work together on output and recharge together at the same speed. As a result, less pressure is placed on the charger and there is no overheating. If solar battery banks or emergency power systems are correctly balanced, they will work smoothly, but if not, they could shut down.

Heat Management in Parallel Battery Systems

Heating can become a serious issue when running several batteries in parallel, either under high load or in small spaces. The wiring and battery contain some resistance and so current passing through them warms up as a result. If no action is taken, the maximum heat can cause thermal runaway, lessen battery performance or even ruin the cells and their components. In case of extreme overheating, the battery can inflate or even catch fire.

Airflow should be possible between battery units by giving them enough space when they are arranged. As a result, heat can disperse on its own and does not remain enclosed among packed cells. Quite often, systems or enclosures that need to reach high performance rely on fans or heat sinks for active cooling. Things such as thermal pads and insulation barriers help direct or absorb extra heat from the system.

You should also pay attention to temperature by using sensors and settling for thermal cutoff switches. The system will either close itself or let the user know if temperatures get too high. When heat control is good, the battery stays protected and its life is prolonged because all the parts aren’t damaged by the heat. Effective thermal management in DIY powerwalls, robotics or electric scooters can decide between a system that survives and one that does not.

Troubleshooting Common Issues in Parallel Battery Setups

As with all electrical systems, there are issues with parallel battery setups that must be spotted and handled quickly. A problem that often occurs is that batteries don’t all have the same voltage level. When resistance differences arise inside an organ, particularly when the cells age or when connections are damaged in batteries connected in parallel, this problem can occur. Regularly monitoring voltage in a system can catch any problems early and keep it from harming the equipment.

Another problem that appears often is that batteries generate additional heat during their charging or discharging cycles. Possible reasons are loose or corroded terminals, unsuitable wires or damage to one or more batteries. A battery that stays hotter than the individual battery may be wrong or mismatched and needs to be tested separately. Also, connecting batteries by daisy chaining rather than using a common bus bar can result in various batteries receiving uneven current, wearing them down and producing dangers.

Finally, a few users report that their storage capacity drops more rapidly than usual or that their parallel systems run for a shorter time than expected. Apparently, only one weak cell is dragging the whole bank down. By testing each battery under a load, especially when using three batteries it’s more likely to spot the battery that’s worn out. Quality parts, proper cabling and a dependable battery management system lessen these problems and improve the system’s dependability. Having lawn mower parts and tools for finding problems will save you time when something goes wrong.

Charging Considerations for Parallel Battery Packs

There are pros and cons when charging batteries in parallel that need to be recognized for the charging to be safe and effective. An advantage of connecting batteries in parallel is that each cell sees less stress from the charging current , since all the batteries are sharing the load. With the same voltage, all the batteries can be charged at once using only one charger.

It’s important that the batteries being charged together all have a similar state of charge (SOC) when they are connected in parallel. Suppose one battery in a group is nearly empty and can’t hold a charge, it will need more current than the others which may damage or overheat your power bank. This problem can be avoided by charging the batteries one at a time up to the same voltage level. A charger with active circuitry or a BMS helps you keep track of every battery’s performance as you charge.

When several charging circuits are used in parallel, the charging process for large systems can be sped up. The batteries aren’t overworked because the current is shared by many batteries. Nevertheless, all the parts such as the wiring, connectors and charger, need to be able to handle the total current used by the vehicle. You should always watch temperature, voltage and current while your battery is charging to avoid problems and lengthen its life.

Integrating a Battery Management System (BMS)

Any advanced structure made of parallel batteries is specialized with a Battery Management System or BMS. Make sure the battery pack stays safe and operates correctly by paid attention to voltage, current, temperature and charge every moment. When using a parallel setup, a BMS ensures that every battery has an equal charge so that all cells are kept under their safe bounds.

In advanced ways, a BMS helps deal with risks of overcharge, over-discharge and overheating, problems that arise when many batteries are connected. Under dangerous conditions, it can interrupt the power between the pack and either the load or the charger to keep things from getting damaged. Bringing a good BMS into play during DIY projects will help greatly in the life span and safety of your batteries. Some brands supply BMS models with Bluetooth connectivity so you can watch the battery’s status on your phone or laptop.

The battery chemistry (either Li-ion or LiFePO4), the number of batteries and the current and voltage the system can handle should guide your selection of a BMS. Matched results should be expected between the batteries and the application. Appropriate wiring of the BMS is vital, not only the choice of which BMS is best for your vehicle and its second battery . If handled correctly, a victron system BMS can upgrade basic batteries into a strong power system meant for solar, electric vehicles and remote electronics.

Advantages of Parallel Over Series Connections

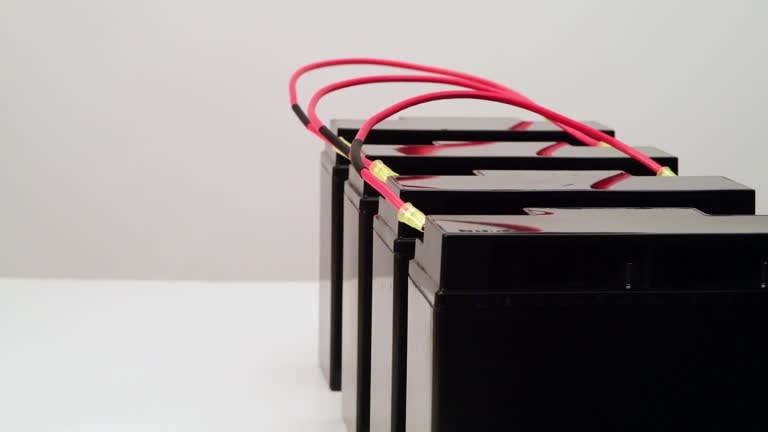

It is usually better to connect batteries in parallel when you need a longer time with the device and guarantee safety. There is a big advantage when it comes to increasing how much energy the system can hold (in amp-hours) without influencing the voltage. As a result, parallel arrangements are well suited for devices that must work for extended periods on a single battery charge, including LED lights, electronics on the go, and considering the appropriate cable size for specific power banks.

A further benefit is that systems become more resistant to failures. Paralleling batteries means that the loss of one battery will not immediately end the system’s operation, though its performance will be less than before. When you use a series of batteries, the failure of just one unit can make the whole system lose power. Also, since batteries in a parallel system work at the same voltage, it’s rare for there to be voltage imbalances that strain devices or components.

In addition, parallel systems tend to be simpler to scale than other systems. If you need more battery power, just add another battery and the level stays the same which helps keep your accessories and chargers compatible. Being able to scale helps parallel battery systems be adaptable and future-ready for people working on energy projects, regardless of their experience. No matter if you’re off the grid, building an emergency system or designing a device for travel, the parallel method ensures safety, stability and efficiency for future upgrades.

Importance of Using Identical Batteries

Batteries should be as identical as you can get them in voltage, capacity, age and chemistry when used in parallel. Because of the uniformity, the load is evenly distributed, greatly improving the system’s safety and efficiency. If the batteries are not the same, the group will always have one battery struggling to compensate for the underperforming ones when connected in parallel , shortening the life, causing overheating or letting some fail.

Identical batteries can prevent sudden and unsafe surges that might otherwise occur when they are connected. If there is only a small difference in voltage between two batteries, a lot of current can move from the higher-voltage one to the lower-voltage one. Such metabolic stress results in ineffective work and damage to cells. As a result, it is suggested to fully charge batteries before you connect them in parallel.

Equally sized batteries make it possible for every part of the system to work and last the same time. Knowing that each battery in a solar power or electric vehicle system will drain equally, gives the assurance needed for proper planning. Unless all the batteries in the bank are equal, you shouldn’t change just a couple, since the new ones might wear out more quickly and work harder than the others. The long-term success of any battery parallel system depends on standardization.

Common Mistakes in Parallel Battery Setup

A usual error in setting up parallel batteries is not bothering to balance the voltage levels between them before joining the circuits. If there’s a big difference in voltage among the batteries, the fully charged cells may rush high current to the lower one, leading to overheating or long-lasting damage. Charge batteries to the same voltage level first with a charger before putting them in parallel.

A third issue sometimes seen is incorrect wiring. If you use thin wires for high current loads, they can overheat, lose voltage or end up causing a fire. Unbalanced lengths on wiring can also create issues, as a few batteries will get far more current than others. Ensure you use thick, not too long wires that match each other when making all connections and keep all connections clean and firmly attached.

Some people also ignore the value of fuses or circuit protection. In a parallel arrangement, if one battery shorts or fails, it could receive all the energy from the other batteries which could become very risky. Fuses or circuit breakers placed between all batteries will insulate problems and keep the entire setup protected. Slipping a battery management system (BMS) out of the design can cause major problems. With a BMS, the battery states are kept in order and under control, but without one, there is a much greater risk of imbalance and thermal runaway.

Troubleshooting Parallel Battery Systems

If problems develop in a parallel battery system, looking for the cause using troubleshooting helps determine if the problem is related to the batteries, the wiring or other parts. One important thing to do is measure each battery’s voltage separately when not connected to the system. If two or more batteries display different reading levels, they may not work properly and need to be charged or changed.

Another sign that there is a problem is if your phone doesn’t charge or lose power in a regular manner. A difference in battery life could mean that one battery has an inconsistent internal resistance or a different amount of wiring than another, resulting in uneven distribution of power. You can find such imbalances by checking the current flow from every battery with a battery analyzer or multimeter. In newer and more effective systems, clever BMS devices record usage information which helps users discover issues earlier.

There are also cases where batteries will heat up unexpectedly which is why thermal issues matter. Such an issue usually means there is a short circuit inside the device or it’s consuming more power than it can handle which must be checked immediately. Make sure to check the internal temperature regularly in the first several hours when you have a parallel setup. Many cases find that fixing a single battery or a poor connection brings the circuit back to normal and efficient operation. Taking care of your battery bank by inspecting and maintaining it regularly will increase its safety and help it work for longer.

Real-World Applications of Parallel Battery Configurations

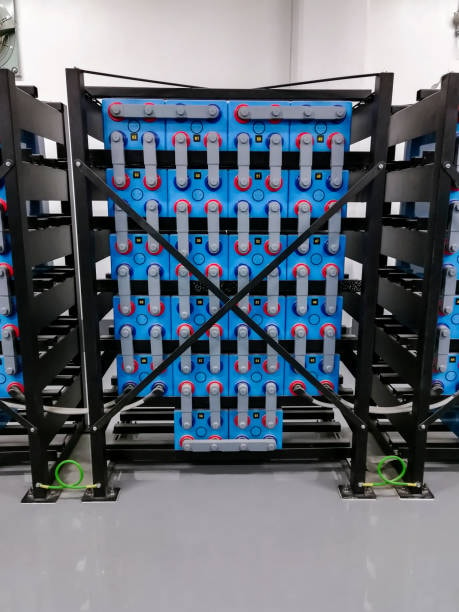

Parallel battery setups are applied in many situations where a long-lasting run and stable power source are required. One simple way to use set points is in off-grid solar power systems. To support a single 12V output and increase its capacity, the batteries are placed in parallel. As a result, homeowners or those using solar power at remote sites can use their stored energy at night or on days without sunlight and the voltages will not be affected.

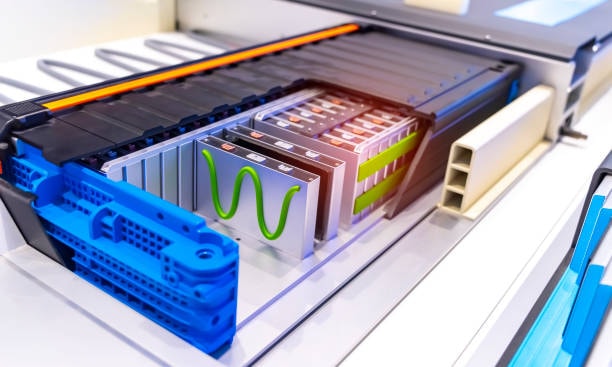

Both types of configurations are used in electric vehicles (EVs) quite often. Parallel wiring of the battery pack draws more power to the motor which increases the distance the car can travel before its next charge. If there was only a single battery, it would either drain fast or not furnish enough power for the vehicle’s motor. When parallel connections are managed right, a stable energy flow is enabled and battery cells remain safe from being discharged too much, especially when using one battery .

Portable electronics and devices that store backup power all use parallel configurations. Items such as power banks, cordless tools and medical equipment use steady power and depend on longer battery life which serial configurations don’t provide. More amp-hours in a device mean it can be used for longer without needing its battery recharged. So, parallel batteries are just as vital for saving lives as they are for smooth and pleasant use.

Summary and Best Practices

If you connect batteries in parallel, their energy store will increase, but the output voltage will remain the same. It helps systems last longer which explains why it is appropriate for energy storage, electric cars and power backup. But you need to have a clear understanding of battery systems and wiring before using this layout to avoid reaching the maximum limits . Failing to address them can result in problems or major dangers.

The first step to safeguarding your setup is to use identical batteries in terms of voltage, capacity and their chemical composition. Try using no more than two battery wires, using fuses or protection circuits and perhaps consider a battery management system to maintain proper performance and prevent problems. Monitoring voltage, the direction of current and temperature can help catch any troubles right away. These steps are important for safeguarding what you’ve invested in and your equipment.

All in all, using parallel battery connections is a simple way for people to boost their power supply without juggling voltages. If carefully set up, they ensure energy is stored reliably, efficiently and for expanding capacity. Whenever you connect batteries in parallel, you increase their efficiency and help your devices last a very long time.

Balancing Current Flow in Parallel Battery Systems

One important issue that appears when batteries are connected in parallel is an unequal flow of current among their cells. Even when all the batteries are identical, discharge and charge speeds may still vary due to small differences inside the battery cells or in their charge. Because of this, some batteries may become too heavily influenced, leading to less efficiency and a greater chance they will fail prematurely.

For this reason, it helps if the individual battery in your charger are the same in age, brand, capacity and voltage before you link them. It is commonly recommended to charge all batteries to the same level before beginning the installation. By doing this, the batteries have an even current which helps prevent one from being less healthy than the others.

Furthermore, using a battery balancer or an active balancing circuit is a good, prolonged approach in bigger or more complicated systems. By regularly watching the batteries’ voltages, these devices move current to balance the load across the whole bank. As a result, batteries last longer, function optimally and are less likely to experience thermal events or wear out unevenly in systems demanding much current.

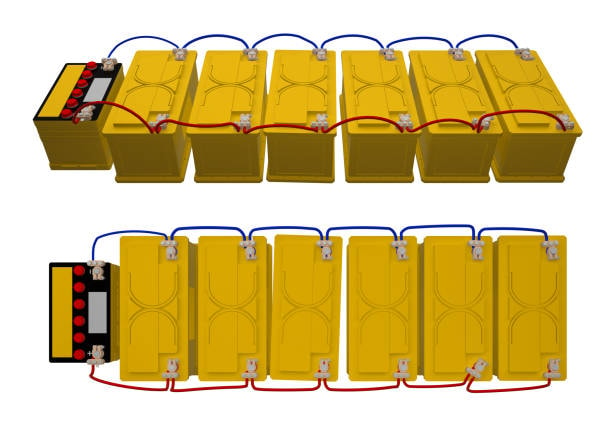

Combining Parallel and Series Connections for Hybrid Setups

Often, more complex batteries use both parallel and series connections together, resulting in what’s called a series-parallel or hybrid setup. This method stands out when both high voltage and a great amount of energy are required which is true for electric vehicles, solar inverters and broad energy storage systems. It offers the ability to choose voltages and amp-hour limits that are just right for each situation.

By way of example, if you are looking for a big 24V bank, attaching the batteries in parallel will increase the storage capacity and connecting them in series will increase the voltage. A properly designed and implemented setup, such as a victron system, ensures the power and storage needed for larger applications, plus strong and efficient system operation.

A hybrid setup needs both careful planning of the design and guaranteed cell matching to keep all batteries working correctly together. When systems are large, making sure wire lengths are the same, fusing is correct and equipment is accurate matters even more. If the voltage, resistance or state of charge of the battery bank are not equal, the harder-working section can suffer faster damage and failure.

Environmental and Safety Considerations

Any battery arrangement, including a parallel arrangement, requires being designed with the environment and safety in mind. If batteries are used incorrectly — by not connecting them well, overcharging them or overheating them — they may leak chemicals, start fires or explode. Dealing with larger currents through parallel wiring requires great caution to not cause such accidents.

Ensuring good ventilation is very important when using batteries in any closed space. While 18650 cells are safe because they are sealed, other batteries, for example lead-acid, can release gases when used or charged. If air doesn’t move freely in your home, heat or toxic gases can accumulate. Furthermore, batteries must be separated from substances that may catch fire, water and sunlight in order to decrease possible environmental risks.

It’s always a good idea to remember how to dispose of and recycle batteries. These parallel-wired batteries will deteriorate and you will need to change them eventually. Because they feature metals and chemicals that harm nature, you should always recycle them by using certified e-waste or battery recycling programs. When you properly manage your battery at the end, you help protect the environment and finish the life of your energy system safely.

Battery Management Systems (BMS) in Parallel Connections

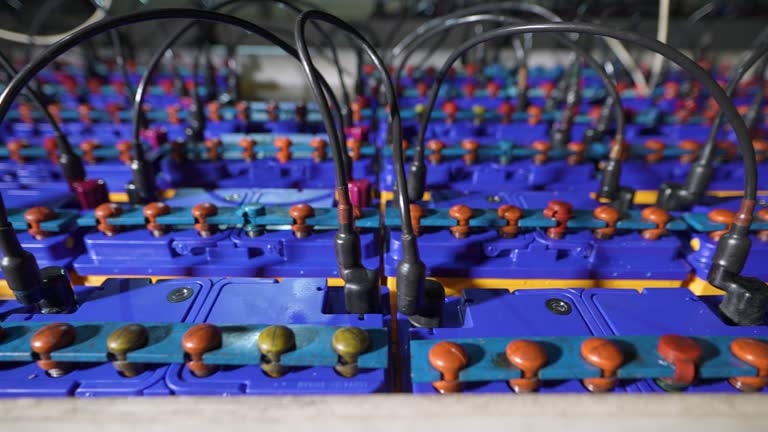

Using BMS is necessary when parallel connecting more than two batteries. An effective battery monitor and BMS makes sure that every battery gets monitored for voltage, cycles and high/low temperatures, so all batteries remain safe and efficient. A missing BMS increases the chance of battery imbalance which could result in a drop in battery capacity, too much heat or even a failure in several batteries linked to the system.

Parallel arrangements rely on the BMS to share current load. It spreads the workload across the entire battery pack, so none of the batteries become worn out too quickly. Such batteries are useful in electric vehicles and solar battery banks, where there is a high level of activity. A properly installed BMS detects problems early and either cuts off power from faulty batteries or makes them noticeable to the user through warnings or indicators.

Additionally, BMS technology is now featuring wireless modules, intelligent diagnostics and cloud services. Advanced parallel batteries used in energy storage let users observe the condition and operation of each battery pack from a distance. With a BMS in place, you boost safety, increase how long your batteries last and make your system more efficient.

Real-World Applications of Parallel Battery Systems

Using BMS is necessary when parallel connecting more than two batteries. An effective BMS makes sure that every battery gets monitored for voltage, cycles and high/low temperatures, so all batteries remain safe and efficient. A missing BMS increases the chance of battery imbalance which could result in a drop in capacity, too much heat or even a failure in several batteries linked to the system.

Parallel arrangements rely on the BMS to share current load. It spreads the workload across the entire battery pack, so none of the batteries become worn out too quickly. Such batteries are useful in electric vehicles and solar battery banks, where there is a high level of activity. A properly installed BMS detects problems early and either cuts off power from faulty batteries or makes them noticeable to the user through warnings or indicators.

Additionally, BMS technology is now featuring wireless modules, intelligent diagnostics and cloud services. Advanced parallel batteries used in energy storage let users observe the condition and operation of each battery pack from a distance. With a BMS in place, you boost safety, increase how long your batteries last and make your system more efficient.

Summary

Many people connect batteries in parallel to boost the power and practical runtime of their battery bank, without increasing the battery voltage. Thanks to this method, lead acid batteries unite, along with solar panel systems, to provide enough current to run devices or systems for a more extended time. This application appears frequently in energy storage batteries for renewables, transportable electronic devices, electric cars and do-it-yourself electrical projects. Key subjects such as stable voltage, where current is sent, how things are safely powered, correct wiring and balancing energy have all been widely discussed.

Parallel connections make it possible to handle more data, extend battery life and design systems in several different ways. However, to use these advantages, engineers have to ensure batteries are matched, currents are distributed evenly and batteries are kept safe through using protection circuits and monitor systems. Battery pre-balancing, installing fuses and equipping bank with battery management systems allow the batteries to be stable and long lasting. Also, system efficiency and sustainability depend on taking care of the environment, combining series and parallel parts and looking after the system for its useful life.