Introduction

Portable electronic devices and electric vehicles now use the 18650 battery as their essential component for energy storage. Our experience using electronic devices and storing energy now depends on this 18mm x 65mm lithium-ion battery cylinder design. Thanks to its unique engineering the 18650 battery transforms into an advanced power source despite looking like an enlarged AA battery. This complete guide explains why 18650 batteries are exceptional and describes their inner workings plus details their uses across many industries plus practical battery selection tips, including insights on lithium ion rechargeable battery technology li ion batteries .

The 18650 battery benefits influence many industries other than consumer devices. These cells made product breakthroughs in renewable power storage systems, power banks, electric vehicles, and hand tools that were not possible with outdated battery technology. The growing adoption of electricity and portable power requires us to understand 18650 battery features for everyone involved in power management.

The Fundamentals of 18650 Batteries

Physical Characteristics and Nomenclature

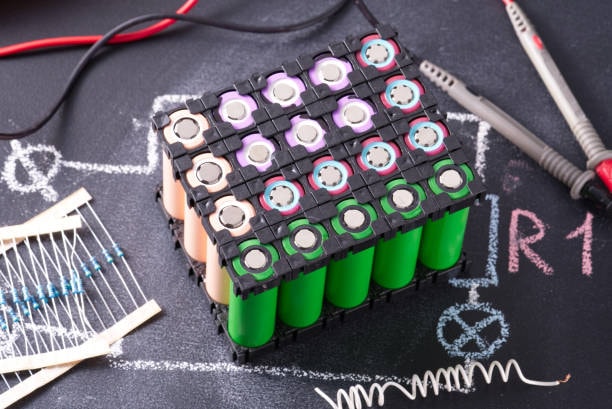

18650 stands as a set physical dimension code to indicate the battery measurements without referencing its electrical data. The battery size includes 18 millimeter diameter as two digits followed by 650 tenths of millimeter length as three digits. An 18650 battery has a diameter of 18mm and extends 65.0mm in length. Companies around the world produce 18650 cylindrical lithium-ion cells as a common standard which makes them easy to use across different products and devices battery voltage.

At 45-50 grams each 18650 batteries stay quite lightweight despite generating a lot of power. Their straight design maintains stability under battery charging and discharging actions to keep the cells safe if they get made according to quality standards. Inner components and negative power connection live inside the metal case made from steel or aluminum while a special cap works as the positive terminal. Users can integrate the battery into different devices with battery compartments through its basic design, but should be cautious when using unprotected batteries low voltage protection .

Manufacturing in large quantities has lowered product prices and made the batteries much better through decades of improving production processes. Standardized batteries work for all users because they match regular replacements from many different suppliers unlike locked brands whose batteries have specific formats portable chargers.

Chemical Composition and Working Principles

The primary element of 18650 batteries represents rechargeable lithium-ion cells which work through lithium ion movements between electrodes to deliver power. They typically consist of:

- A battery cell’s positive side (cathode) exists as either lithium cobalt oxide (LiCoO₂), lithium manganese oxide (LiMn₂O₄), lithium iron phosphate (LiFePO₄) or lithium nickel manganese cobalt oxide (NMC) formulation.

- You find the negative electrode made from stacked graphite that lets lithium ions insert within it.

- The membrane connects both electrodes without letting them touch to enable ion movement.

- Lithium salt-based liquid solution lets ions flow through organic solvents.

- A strong metal enclosure holds all battery parts and functions as the power output terminal.

- The positive terminal safety-equipped cap serves as an insulated top part in the unit.

When the battery functions lithium ions move from negative to positive through the electrolyte and separator creating electrical energy at the external connection. The charging phase happens when lithium ions return to the anode and position between graphite layers. The battery system works backwards and forwards up to many charge-cycle counts as displayed through its product ratings and user behavior.

The type of material used in the cathode determines how well the battery performs portable electronics. The combination of lithium cobalt oxide generates high energy but creates thermal risks while lithium iron phosphate demonstrates strong safety and endurance with limited energy storage capacity protection circuitry. The producer selects specific battery components through the blend of materials that prioritize needs including safe operations, power impact, power storage and price range same voltage.

Performance Specifications

The wide industry use of 18650 batteries results from their strong performance parameters, including their ability to deliver long lasting power .

- Nominal Voltage: Each chemistry type yields voltages around 3.6 to 3.7 volts but the exact range depends on battery compositions.

- Energy Density: Batteries usually hold 1800mAh to 3600mAh power and have advanced variants with elevated storage limits.

- Cycle Life: Approximately 200-260 Wh/kg, among the highest of commercially available battery technologies

- Discharge Rate: Quality types of cells endure 300 to 1000 full charge-discharge routines yet maintain 80% of their initial power rating

- Operating Temperature: Regular battery cells have 1-2C discharge rate capabilities but high-drain cells work at 10C discharge rates or faster.

- Self-discharge Rate: The battery operates best in room temperature and works reliably between -20°C and 60°C.

- Internal Resistance: Approximately 5-10% per month at room temperature

- The battery delivers energy hindrances and produces extra heat when its internal resistance ranges between 20 and 60 milliohms.

These standards change depending on the model and producer of the batteries. User populations usually pick high-end 18650 cells from Panasonic electric bicycles, Samsung, LG and Sony because they prove more reliable and perform better but cost more than standard options.

The 18650 battery system serves many applications because its properties blend well for prolonged light power usage and intense short current spikes. 18650 batteries have become useful in many different business sectors because of their flexible performance options, which significantly enhance battery life .

Evolution and Development History

Origins and Early Development

In 1970 scientists M. Stanley Whittingham, John Goodenough, and Akira Yoshino started work on lithium-ion batteries but Sony became the first company to sell practical lithium-ion batteries in the early 1990s. The 18650 format gained success fast because its dimensions perfectly matched the amount of power it delivered good charger. The first models of these batteries entered laptop computers in the 1990s to defeat NiCd and NiMH technology with their increased energy storage and no memory effect issues, paving the way for applications in e bikes .

18650 cells from the early 1990s provided 1200 to 1500mAh which supported portable electronic devices then but are weak by present standards. Modern producers have enhanced battery performance through scientific improvements to reach higher mah values, such as 3000mAh, at the same size as earlier products.

The standard names for lithium batteries come from industrial measures that describe cylindrical cells using their specific sizes. The industry has used this naming system consistently despite advancing battery technology since it ensures stability in a fast-changing field.

Recent Technological Advances

In the past decade manufacturers improved 18650 technology successfully since newer battery designs appeared.

- Electronic devices now accept more lithium ions because of new high-capacity anode chemistry based on silicon-silicon composites

- Progress in creating powerful cathode materials that allow more energy storage over a broader operating voltage range

- Experienced battery specialists develop new electrolytes that keep batteries safer and work better across extreme temperatures.

- Advanced battery control technology lets batteries run better while stopping harmful activities

- Better and more consistent production happens through advanced machinery and full-quality inspections that reduce product costs.

- The creation of better separator materials builds battery protection and lowers electrical resistance.

- Special electrode coatings improve material protection and measured activity length

New battery products have not decreased the popularity of the 18650 model which continues to improve through technological advancements rc cars. The 18650 battery has maintained its small dimensions throughout the years while its battery capacity tripled from inception to today.

Milestones in Commercial Adoption

The 18650 battery passed several important stages as it transitioned from industrial component to widely used power supply.

In 1991 Sony began selling commercial lithium-ion batteries which included 18650 as one of their first formats.

Between 1994 and 1998 laptop manufacturers quickly adopted 18650 batteries which made battery production more efficient and lowered production costs good cells.

LED flashlight manufacturers adopted 18650 cells to produce high-power lighting products for consumer sale between 2006 and 2008.

Tesla Motors picked 18650 cells as the main power source for its electric vehicles during this period which created extensive demand from 2008 until 2012.

The power enhancement industry decided to base their battery packs on 18650 technology between 2010 and 2015.

From 2014 until today our production output grew extensively because our battery products joined many unique markets.

Market growth throughout these periods required companies to adjust their cell technology to match exact performance standards set by each new product application.

Applications and Uses

Consumer Electronics

Many products use the 18650 battery because it holds optimal amounts of energy with standardized rechargeable features.

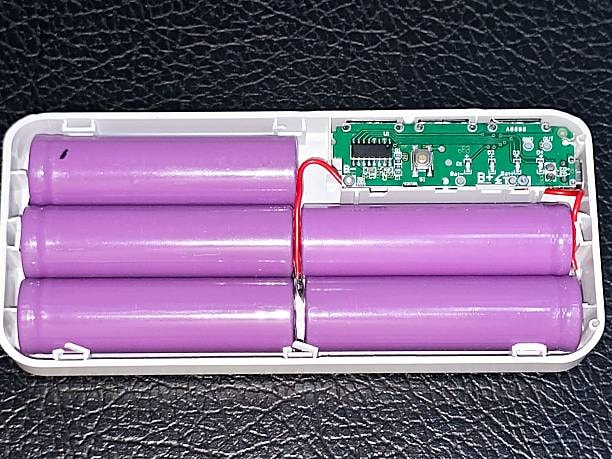

- Laptop computers come in sets of 6 to 9 cells as built-to-order rechargeable batteries.

- Powerful flashlights and headlamps serve people who work outdoors and prepare for emergencies plus professionals who depend on them.

- Users prefer portable audio devices that need continuous music playback.

- The portable charging devices power both smartphones and tablets.

- Electronic smoking devices and vaping pens use the device’s powerful power supply

- Digital cameras and video tools contain reliable power systems

- Power tools serve both amateur and professional users when they need devices that provide durable runtime and good weight balance.

- Cordless vacuum cleaners operate through electrical power sources at home

- Gaming controllers and portable gaming devices

- Video doorbells and home security cameras

- Emergency backup lighting systems

Small electronic devices count on these batteries either as single units or grouped together because they deliver energy for extended periods. ventional power cells make product development faster and more dependable because they work exactly as promised.

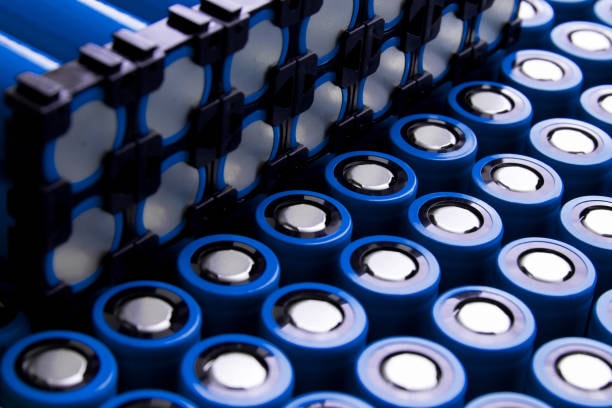

Electric Vehicles and Mobility

The 18650 battery made electric vehicle development possible because it enables vehicles that travel far and power as well as other mainstream vehicles.

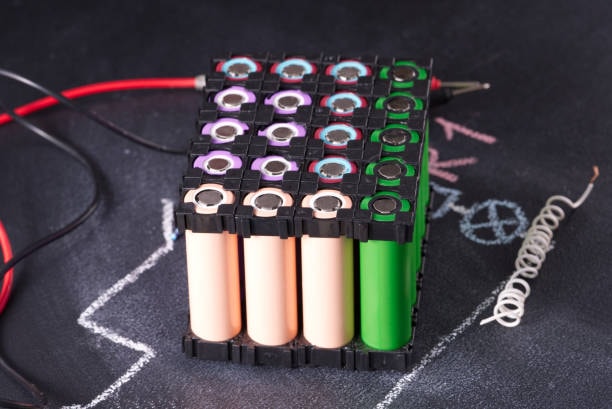

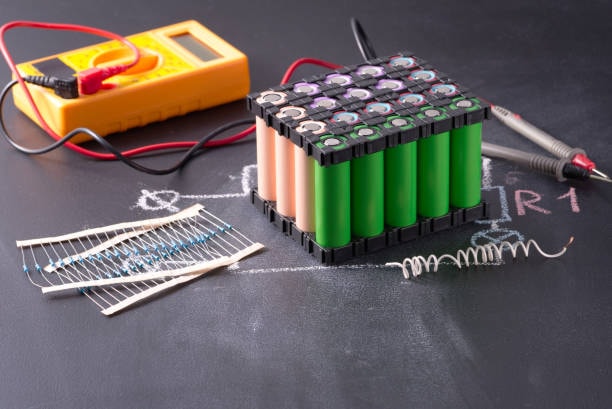

- Tesla Model S original battery units had over 7,000 18650 cells which were packed into modules and monitored to keep them safe from overheating and imbalance in charging.

- Small rechargeable electric scooters and bicycles require packs of 18650 units to deliver power over extended distances at different speeds.

- Personal mobility devices like hoverboards, electric skateboards, and self-balancing unicycles

- Electric motorcycles need high energy density batteries for good driving distances.

- Golf carts and neighborhood electric vehicles

- Portable charging stations for larger electric vehicles

Larger battery packs make from small cells give better temperature control and protect against faults while mass production becomes easier. Electric vehicles still apply the core knowledge gained from developing batteries using 18650 cells even though newer electric cars employ 21700 cells.

Energy Storage Systems

The batteries aid power backup and renewable energy production operations:

- Home energy storage systems consist of multiple 18650 batteries which collect solar power for nighttime power needs

- Solar-powered devices need rechargeable batteries which these cells serve for storing energy during lightless times.

- Systems that use backup power for necessary medical equipment and communications technology

- Power supply devices named UPS protect electronic systems at work.

- Power stabilizing systems deliver power to the grid during times of high demand or power disruptions

- Remote monitoring stations and scientific equipment in off-grid locations

- Our telecommunications systems immediately switch to backup power in any power outage to keep operations running.

The uniform size of 18650 batteries allows them to work together easily because they can be linked serially and parallelly to form larger battery packs. The product design environment enables users to customize power delivery and lets them update individual cells while ensuring they do not exceed the maximum charge voltage.

Industrial and Specialized Applications

Customers in specific sectors depend on our high-performance 18650 batteries under demanding operational environments.

- Patient care tools and portable medical tools demand uninterruptible power sources particularly for infusion pumps and diagnostic instruments.

- Military equipment and tactical gear like night vision devices and field communications

- High-performance satellites and drones need batteries with superior energy capacity as their primary operation power.

- Scientific instrumentation and research equipment operating in remote locations

- Critical infrastructure components need backup power supplies in traffic control systems and emergency messaging services

- Robotic and autonomous systems depend on batteries that provide enough power with excellent functioning results

- The devices operate underwater by using diving lights and motors.

- Portable test and measurement equipment for field technicians

Their outstanding performance qualities enable these batteries to operate safely in systems where interruptions cannot occur. Tests and validation processes performed on these batteries make them certification-ready for specific applications.

Technical Aspects and Considerations

Protection Circuits and Safety Features

Quality 18650 batteries use several automatic safeguards to stop unsafe battery actions.

- Protection Circuit Modules (PCMs): PCMs monitor electronic safety systems that protect batteries during overcharging at 4.2-4.3V, overdischarging at 2.5-3.0V, short circuits, and current limits to prevent damage and safety threats to users

- Positive Temperature Coefficient (PTC) Devices: The positive temperature coefficient devices on batteries reset themselves by increasing resistance as a protective measure when they recognize overheating situations before system breakdown

- Current Interrupt Devices (CIDs): During abnormal pressure buildups in cells CIDs use mechanical parts to break electrical contact which disables the battery permanently before it ruptures

- Pressure Relief Mechanisms: The battery includes safety valves that release dangerous gases when internal pressure reaches dangerous levels either from charging mistakes or breakdown within the cell.

- Thermal Runaway Prevention: Advanced battery cells have many safety measures to avoid thermal breakdown leading to fire hazards

- Flame-retardant Separators: Built-in fire-resistant separators stay intact under high heat to stop electrical shorts

- Overcurrent Protection: Systems either mechanical or electronic protect batteries from drawing too much power safely.

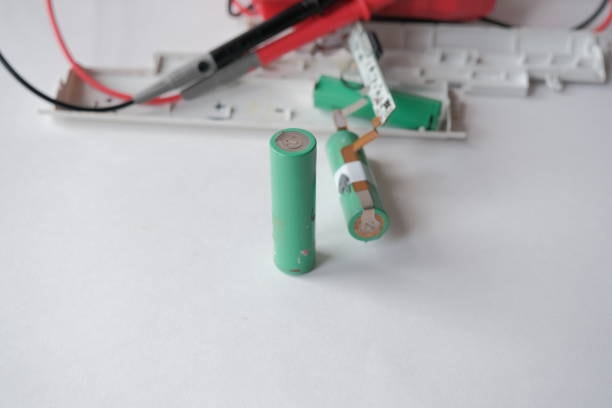

Protected 18650 batteries include built-in features or external safeguards that result in battery lengths known as 18650P cells. Because protected cells bring added safety features their advantages make them the superior choice when used by consumers.

Charging and Discharging Characteristics

Right charging methods ensure safety and extend the life of every 18650 battery type.

- The charging process includes a phase where power flows steadily (CC) before changing to voltage control (CV)

- Each battery cell accepts a full charge to 4.2 volts but certain chemistries work at various different voltages

- The best charging speed for lithium batteries is between half a charge and one charge of their rated capacity hourly.

- A battery stops charging fully once its current declines to 0.1C rates during the CV phase.

- Protecting cell components requires ending discharge between 2.5 and 3.0 volts

- Fast charging speeds up battery aging and produces more heat inside the device

- Keeping track of cell temperatures during charging ensures battery safety since charging should stop below 0°C and above 45°C.

- Charging many cells in sequence needs proper balance to keep each battery from taking in excessive voltages

Temperature extremes harm battery performance by cutting capacity to half at 0°C and creating dangerous heat risks. Beyond 500 charge-discharge cycles the battery will deliver only 80% of its initial capacity at most depending on operating conditions.

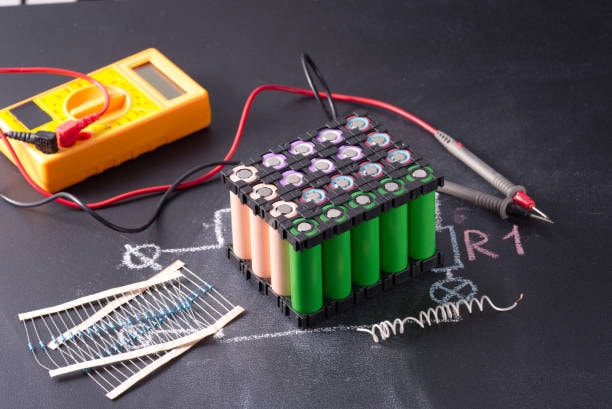

Battery Management Systems

A battery management system becomes necessary for battery packs made of several 18650 cells to maintain safety and reliability.

- The battery system uniformizes the power flow among cells placed one after another in a rechargeable battery module.

- The system watches battery temperatures to stop damage by adjusting power use or activating fans

- The battery system tracks both SoC and SoH data to help users manage their packs effectively.

- The system connects to other devices through connection ports that send battery data.

- Technology-based learning methods automatically select charging plans to create better results and longer life

- Fault detection finds and removes defective cells so they do not harm the whole battery pack

- Thermal management systems save battery packs with heating when conditions are cold while using cooling methods when needed.

- The system records data for performance evaluation and helps maintain the unit before potential issues arise

These systems must operate flawlessly with numerous cells linked together in top-performance electric vehicles. BMS technology starts with basic charge protection systems yet advances to advanced vehicle setups that watch cell voltage temperature and resistance to give reliable power measurements.

Manufacturing and Quality Control

The quality and performance of 18650 batteries rely fully on production precision and thorough quality checks.

- The coating material needs to have constant depth throughout the product to make electrical power flow equally across all areas

- Handling tension at assembly time influences how well electricity passes through the product and affects heat disbursement.

- How we fill batteries with electrolyte determines how well their ions move within the battery and affects its inner resistance.

- Producing batteries through formation procedures starts their electrochemical operations.

- Chemistry within the product stabilizes during aging before it reaches the customer.

- Regular quality tests find problematic cell units before they enter the market.

- Quality-control systems follow how materials and process parameters flow through manufacturing operations.

Leading battery producers utilize advanced technology to check every single cell produced at billions of units. Over many years these production methods have helped create dependable lithium-ion batteries which manufacturers steadily improve today.

Comparing 18650 to Other Battery Types

Versus Other Lithium-Ion Formats

The 18650 runs alongside various lithium-ion battery structures and carries special performance features for different uses.

- 21700 Cells: 21700 Cells became popular mainly because they use larger dimensions (21mm × 70mm) yielding 35-50% capacity increase and are now common in newer Tesla models and advanced battery systems.

- 26650 Cells: These 26650 batteries come as long (26mm × 65mm) power cells which have increased capacity but decreased energy density for strong flashlight applications.

- 14500 Cells: 14500 Cells Arrive in a small format (14mm × 50mm) that resembles AA batteries but uses lithium-ion technology for compact devices.

- Pouch Cells: Pouch cells provide space-saving designs yet their thin design makes them weak compared to cylindrical cells which power smartphones and tablets.

- Prismatic Cells: Prismatic Batteries Come in a Rectangular Shape for Many Electronic Devices but Each Manufacturer Uses This Type Differently

- Lithium Polymer (LiPo): Modified lithium-ion chemistry with polymer electrolyte offering flexibility in shape but typically with lower energy density than 18650s

Each battery layout works best in certain use cases where 18650 technology provides a balanced solution between power density and basic design standards while handling heat and remaining affordable to produce.

Advantages and Limitations

The 18650 format stands out because these benefits continue to support its widespread use in most electronic equipment .

- Manufacturing of industrial-size products produces stable quality at market-best prices

- The batteries perform well at shedding heat because their cylindrical shape allows good heat removal

- Manufacturers sell this battery product everywhere with similar design standards

- Strong mechanical structure resistant to physical damage and internal short circuits

- Since the batteries have been widely used people established recycling services with their network

- Extensive industry experience with safety characteristics and failure modes

- This technology stores more energy than rechargeable battery types that came before it

- Different battery packs combine this element to produce output ranges that customers require.

Multiple issues force researchers to explore new battery system patterns.

- Cylindrical cells provide less energy storage than pouch or prismatic cells because of their round shape.

- Cylindrical batteries have a smaller capacity to deliver power than 21700 and 26650 versions

- Senior designers choose cylindrical batteries for applications that need custom battery shapes and weigh less

- The battery control system needs complex technical support to manage packs that combine hundreds of small cells.

- The fixed battery form hinders customization possibilities when designers aim to match available spaces using pouch cells.

- Applications that need more than 3.7V power require two or more identical cells

- The battery format fails well in slim devices that need flat batteries.

The 18650 battery remains an excellent selection for products that require its dependable performance despite its size and construction limitations.

Comparison with Traditional Battery Technologies

18650 batteries present several better functions over older non-lithium battery types in our analysis.

- Versus Alkaline: The battery functions as a rechargeable unit equivalent to a 3.7V cell with greater capacity and power output without reaching 1.5V.

- Versus NiCd: No memory effect, approximately three times the energy density, higher cell voltage, and lower self-discharge rate

- Versus NiMH: Higher cell voltage (3.7V vs 1.2V), better high-current performance, lower self-discharge for most variants, and better cold-weather performance

- Versus Lead-Acid: Dramatically higher energy density (approximately 6-7 times), much longer cycle life, maintenance-free operation, and no toxic lead content

Because of its advantages the 18650 battery replaces older rechargeable designs yet each technology still finds use in its specialized areas.

Practical Consumer Information

Buying and Identifying Authentic Cells

18650 batteries have become so popular that sellers produce many fake versions to deceive consumers. When purchasing:

- Buy your cells from reliable suppliers and official dealers to prevent purchasing from untrustworthy sellers at below-market rates

- Commercial 18650 batteries avoid real cells that surpass 3600mAh since quality cells maintain capacity between 2000 and 3500mAh.

- Look for official manufacturer logos placed properly with high-level fabrication standards throughout the cell

- Examine cell weight because low-quality replicas tend to weigh less than original products

- Buying cells at abnormally low prices usually leads to receiving materials recovered from trashed laptop batteries

- Look at how professional major manufacturers present their battery packs and protect them from counterfeits

- High-capacity cells designed mainly for energy storage deliver less output power than optimized power cells.

- Check if product makers attach proper batch codes and QR codes for monitoring their work and product traces

- Check if cells are real by using checkers available on major manufacturer websites

Producing real batteries with proven quality are Panasonic/Sanyo, Samsung, LG, Sony, Molicel, and A123 Systems. These businesses maintain extensive research and testing programs that produce battery cells which outperform knockoffs in performance while protecting user safety for longer life.

Safe Handling and Best Practices

Working with 18650 batteries demands following safe procedures to stop accidental problems.

- The permanent electrical connection between terminals presents a fire hazard capable of detonating the battery

- Keep 18650 batteries charged between 40 to 60 percent when you do not need them to extend their lifespan

- Do not put any metal items close to the battery terminals especially the loose ones kept in jacket pockets and drawers

- Stay away from both high and low temperatures when using this product

- Check the battery pack daily for cracks or signs of damage and fluid leakage.

- When making battery packs stick to cells made by the same manufacturer with same specifications and production date

- Be gentle when working with the battery to prevent outer casing damage that may start an internal short circuit

- Rephrase with chargers designed to end the charging procedure when lithium-ion batteries need charging

- Keep the cells protected because any alterations can lead to harm.

- Get rid of the damaged battery in a safe manner instead of keeping it as a spare

- Unprotected cells must have battery holders that prevent reverse polarity connection

- Discharging all power from a cell harms it so badly it can never function again

- Installing protection circuits and thermal management belongs in all multi-cell battery pack setups

People building batteries at home should pick devices with built-in safety circuits because these safety features protect against most battery problems better than unprotected cells.

Recycling and Environmental Considerations

It is better to recycle the materials inside 18650 batteries instead of sending them to a landfill.

- The metals lithium cobalt nickel copper and aluminum can return to use in new products through efficient recovery processes.

- Regular trash systems are unsafe for 18650 batteries because they pose fire hazards and release harmful materials into groundwater

- Electronics retailer services let you recycle lithium-ion cells through their company programs.

- Most developed countries maintain exclusive battery recycling centers which accept batteries via mail-in programs.

- Manufacturers run collection systems that accept their used battery products for recycling.

- To recycle batteries needs discharging their energy and covering terminal parts with tape.

- Local authorities require people to recycle their lithium-ion batteries instead of sending them to landfills

- Organizations that recycle batteries handle them safely to extract materials that can be put back into use.ecycling operations safely dismantle batteries and separate materials for reuse

Because lithium-ion battery making affects our environment a lot scientists require proper recycling methods to keep our world sustainable. Extracting lithium cobalt and similar materials for batteries produces major environmental damage plus harms local communities and requires heavy electrical use in production. Environmental effects decrease through recycling because it recovers materials instead of needing fresh mining operations.

Future Trends and Developments

Emerging Technologies and Improvements

Research and production techniques continue to improve the 18650 format.

- Solid-state batteries replace liquid batteries to enhance battery safety and pack more energy.

- Using silicon-dominant anodes will boost lithium-ion battery energy density to twice its current performance level with graphite.

- Better crystal structures at the cathode level brings us enhanced voltage and greater power in cells

- Better manufacturing techniques lower expenses while producing better and more uniform products

- Manufacturers add advanced safety technology to mass-produced electric batteries without reducing performance quality

- Advanced separators with better temperature stability and ion conductivity

- Easier to maintain solid-electrolyte interphase (SEI) protection systems emerge thanks to improved electrolyte additives.

- Studies of cell damage allow us to develop batteries that last longer before needing replacement

- Cell manufacturers incorporate monitoring sensors to display essential health data as battery cells work

Newer battery formats such as 21700 keep appearing yet research ensures that the 18650 remains current and improves constantly in all battery standards.

Market Outlook and Industry Shifts

The worldwide demand for 18650 batteries keeps growing despite rising competition from modern battery designs.

- The market for electric mobility products uses 18650 batteries at rising rates in both light electric vehicle and portable power tool applications.

- Increasing adoption in energy storage applications for renewable power integration

- Although manufacturers still use 18650 batteries despite product designers building batteries for small portable devices

- Manufacturers increase their production facilities especially in Asian countries which hold most of their factories

- Regular environmental rules demand better battery recycling systems.

- Manufacturers of battery cells now expand into making their own materials for production.

- Electrical engineers now produce single-cell battery assembly systems at lower prices

- Areas pursuing energy independence focus more on creating batteries at home.

Top manufacturers acquire more battery plants to work at larger scales with separate businesses making batteries for special uses.

Sustainability and Ethical Sourcing Challenges

As 18650 batteries gain popularity the industry needs to develop sustainable solutions for better market acceptance.

- The way cobalt is mined from the Democratic Republic of Congo creates major ethical problems in the industry

- Extracting lithium causes significant water use issues within desert regions that need special protection

- Energy-consuming production methods release carbon into the environment.

- Current recycling technology does not solve the problem ofdisposing with batteries near the end of their lifespan.

- Alternative chemical compounds made from iron phosphate allow industries to substitute their use of rare elements.

- Traceability programs exist to help companies find minerals responsibly

- Scientists study natural electrode material sources to produce cleaner production approaches

- Under this system producers take full responsibility for recycling batteries through their lifecycle.

Companies in the battery sector will lead 18650 technology through the next several decades by working towards greener solutions for making and using batteries.

Specialized Applications and Case Studies

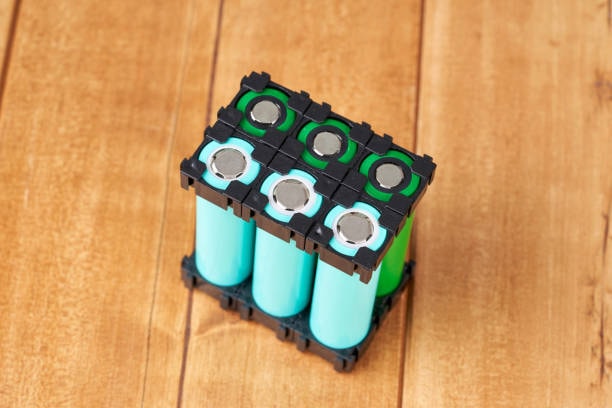

Electric Vehicle Revolution

Tesla Motors adopted a new electric vehicle design when it created batteries from thousands of 18650 cells rather than custom large batteries. This approach offered several advantages:

- Our use of current production lines kept production expenses low.

- Small battery cells could be properly cooled by fluids while maintaining high production standards

- The whole battery pack remained intact while researchers could find and remove faulty cells separately

- Cylindrical battery cells endured impacts better than conventional pouch cell designs did

- By using standard battery parts Tesla gained access to industry improvements as they became available.

After using larger 21700 cells Tesla kept the basic design rules it built with 18650 batteries to help modern vehicles move toward electric transportation. The Model S electric vehicle made it possible to travel farther with its 18650-celled battery pack which helped reduce range anxiety people faced with early electric vehicles.

Power Tool Evolution

Major advancements in cordless power tools happened between nickel-cadmium and lithium-ion 18650 batteries.

- Lighter weight tools with higher power output

- The new batteries now avoid damage from previous repetitive charging problems.

- Higher voltage options through series-connected packs

- Faster charging capabilities

- Longer runtime between charges

- Better performance in cold conditions

Experts in construction and manufacturing started using the better cordless tools because improved models changed their minds. When 18650 became the industry standard tool producers could use upgraded battery cells directly in their designs.

Home Energy Storage Integration

Ste clothing home energy storage systems based on 18650 batteries makes it possible to use solar energy effectively in daily life

- The system stores valuable sunshine energy from daytime hours before using it at night.

- Our system stores power when the grid loses power during outages

- Home owners use stored energy to stay connected in isolated areas

- Shaped-top demand peaks to lessen electricity load results

- The technology helps communities achieve self-generated power through small energy networks

Standard 18650 cells proved useful when Teslas adapted them from small electronics to full home battery systems that help everyday users access renewable energy.

Conclusion

Modern electronics use 18650 batteries as the top example of successful energy storage standards. Its features of high battery power delivery and affordable pricing with multiple design types made the product suitable for many business and everyday use applications across industries. Our modern portable living depends on 18650 technology which made electric vehicles practical and brought compact high-power flashlights into use.

Organized development kept to the fixed battery dimensions allowed scientists to perfect the cell’s inner content rather than seeking new structures. Through advanced engineering the new batteries hold almost triple the energy of old 18650 cells even though they fit within familiar sizes.

The 18650 battery remains useful because its stable production methods and continuous upgrades make it a reliable solution for the next several years. The ordinary 18650 battery will remain essential for both renewable-powered society and mobile power supply because of rising global energy storage needs. The 18650 battery brings important benefits to everyday life as well as plays a key role in making our world greener and cleaner.